CodeSection

Well-Known Member

- Joined

- Feb 4, 2018

- Messages

- 1,655

- Reaction score

- 819

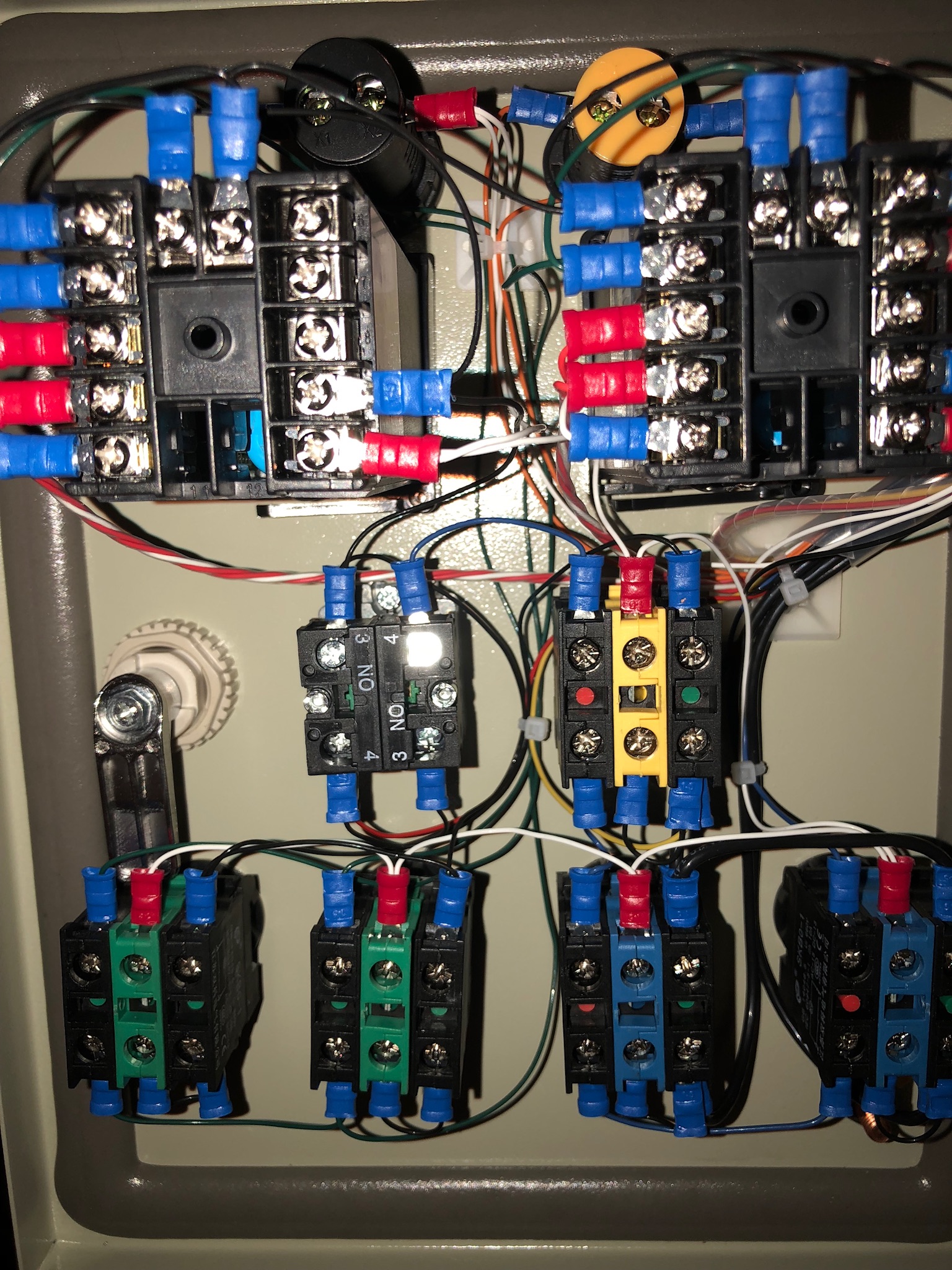

Yesterday, after everything was crushed, hop additions measured, water profile additions added, and 12 minutes into heating my water, my brand new controller made a "pop" noise and the heating element light turned off. When I opened the panel, there was smoke and a smell of wires or plastic burning. The internal circuit breakers did not trip. My electrical 30A breaker did not trip either. I could not see any burning marks on any wires or anything.

I turned off all breakers and then turned them back on to see if that would reset everything. It did not work. The control panel would still light up with everything turning on except the heating element.

Since this was the first time using the controller, I wanted to test to see if anything else had problems. I decided to see if my pumps would work. I opened the valves and turned on my boil pump and had it recirculating water back into the boil kettle. After a minute, I heard another "pop" and noticed all the lights turned off on the controller. Opened the controller, saw the same smoke as before and smelled the same smell as before. This time the breaker in the controller was tripped. Nothing I tried would turn it back on.

So, yesterday was a disaster for my first all grain brew. I plan on contacting the manufacturer of the controller unit on Monday regarding returning the unit to them.

Do you have any ideas why this happened? Could it be bad parts, incorrect wiring or too small wires being used?

To say I was disappointed is an understatement.

I turned off all breakers and then turned them back on to see if that would reset everything. It did not work. The control panel would still light up with everything turning on except the heating element.

Since this was the first time using the controller, I wanted to test to see if anything else had problems. I decided to see if my pumps would work. I opened the valves and turned on my boil pump and had it recirculating water back into the boil kettle. After a minute, I heard another "pop" and noticed all the lights turned off on the controller. Opened the controller, saw the same smoke as before and smelled the same smell as before. This time the breaker in the controller was tripped. Nothing I tried would turn it back on.

So, yesterday was a disaster for my first all grain brew. I plan on contacting the manufacturer of the controller unit on Monday regarding returning the unit to them.

Do you have any ideas why this happened? Could it be bad parts, incorrect wiring or too small wires being used?

To say I was disappointed is an understatement.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)