You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bottle Carbing Idea (Final Data Review)

- Thread starter RukusDM

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

pimento

Well-Known Member

I've been following and replicating RukusDMs experiment since last week and he asked me to post my data here as well.

I bottled a batch of graff on 11/4/10, half I backsweetened and half I bottled with the standard amount of priming sugar for 2.5 volumes.

There were a few differences, mine was a graff instead of plain cider, I used Nottingham yeast and it was bottled only with priming sugar.

For the pressure gauged bottle, I didn't backsweeten, just priming sugar.

11/4/10 - bottled dry 68F

11/5/10 - 5.5 psi

11/6/10 - 8 psi

11/7/10 - 9 psi

11/8/10 - 10.5 psi

11/9/10 - 11.5 psi

11/10/10 - 13.5 psi

11/11/10 - 15 psi

11/12/10 - 17.5 psi

11/13/10 - 20 psi

11/14/10 - 22 psi

As you can see, my priming curve mirrors RukusDMs and matches well with standard keg priming charts for pressure vs vol.

It matches the standard timings for bottle carbing in beers as well.

I also opened a bottle to check carbonation ever 2-3 days and found very little carbing at up to 15 psi, with what i would consider normal carbing only showing within the last day at 20-21 psi.

In the past I have found the plastic squeeze bottle test to be a very unreliable way to judge carbonation. On my first try at pasteurization I blew 2 bottles and popped 2 other caps, on the 2nd batch I pasteurized to early and had almost no carbonation. Even though my squeeze bottles seemed just as firm.

I'll be pasteurizing the backsweetened graff later today, so we'll see if a standard bottle carb will cause bottle bombs. I'll post results after I finish.

Even if this test fails, I'm hoping that by using a pressure gauge we can home in on a reliable pressure that doesn't cause bottle bombs.

I bottled a batch of graff on 11/4/10, half I backsweetened and half I bottled with the standard amount of priming sugar for 2.5 volumes.

There were a few differences, mine was a graff instead of plain cider, I used Nottingham yeast and it was bottled only with priming sugar.

For the pressure gauged bottle, I didn't backsweeten, just priming sugar.

11/4/10 - bottled dry 68F

11/5/10 - 5.5 psi

11/6/10 - 8 psi

11/7/10 - 9 psi

11/8/10 - 10.5 psi

11/9/10 - 11.5 psi

11/10/10 - 13.5 psi

11/11/10 - 15 psi

11/12/10 - 17.5 psi

11/13/10 - 20 psi

11/14/10 - 22 psi

As you can see, my priming curve mirrors RukusDMs and matches well with standard keg priming charts for pressure vs vol.

It matches the standard timings for bottle carbing in beers as well.

I also opened a bottle to check carbonation ever 2-3 days and found very little carbing at up to 15 psi, with what i would consider normal carbing only showing within the last day at 20-21 psi.

In the past I have found the plastic squeeze bottle test to be a very unreliable way to judge carbonation. On my first try at pasteurization I blew 2 bottles and popped 2 other caps, on the 2nd batch I pasteurized to early and had almost no carbonation. Even though my squeeze bottles seemed just as firm.

I'll be pasteurizing the backsweetened graff later today, so we'll see if a standard bottle carb will cause bottle bombs. I'll post results after I finish.

Even if this test fails, I'm hoping that by using a pressure gauge we can home in on a reliable pressure that doesn't cause bottle bombs.

RukusDM

Well-Known Member

I ran a few more tests this morning. My original Pasteurization test only used 2 bottle. It occurred to me there would be more of a bath temperature drop with a full sixpack in there.

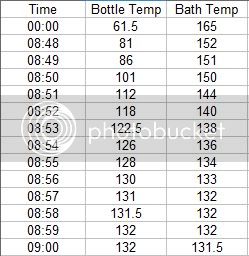

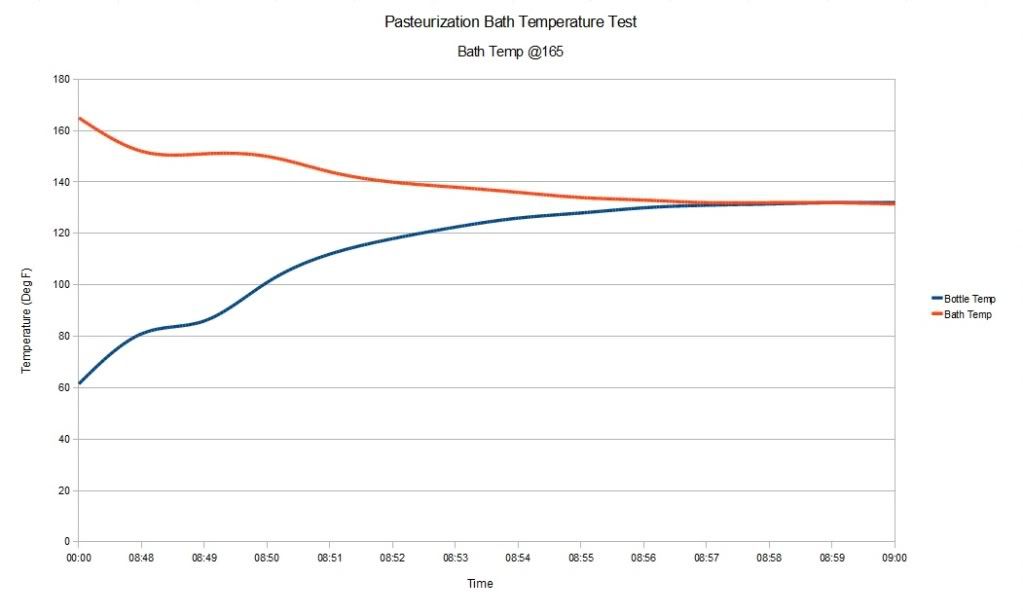

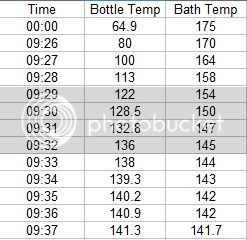

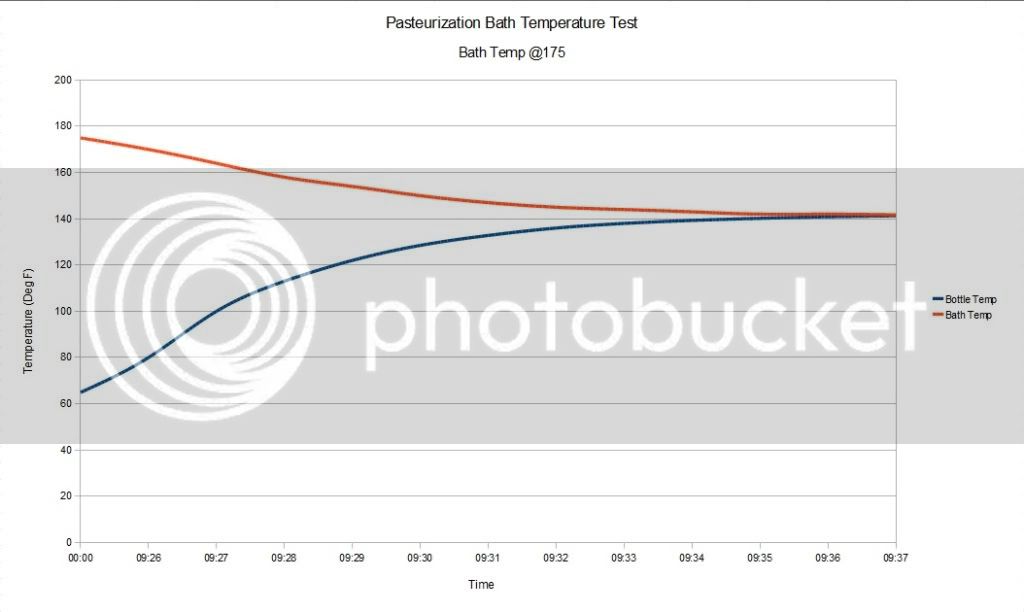

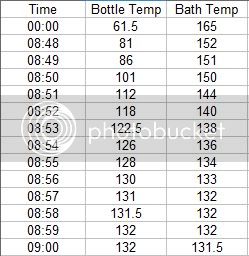

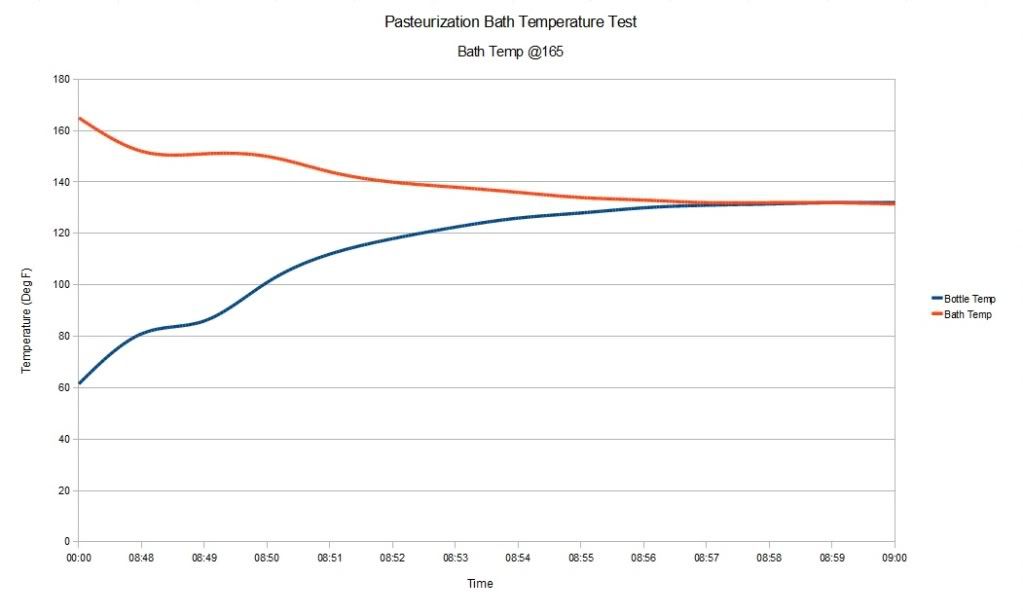

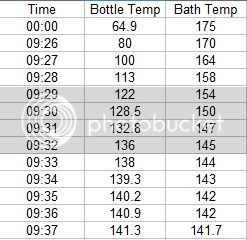

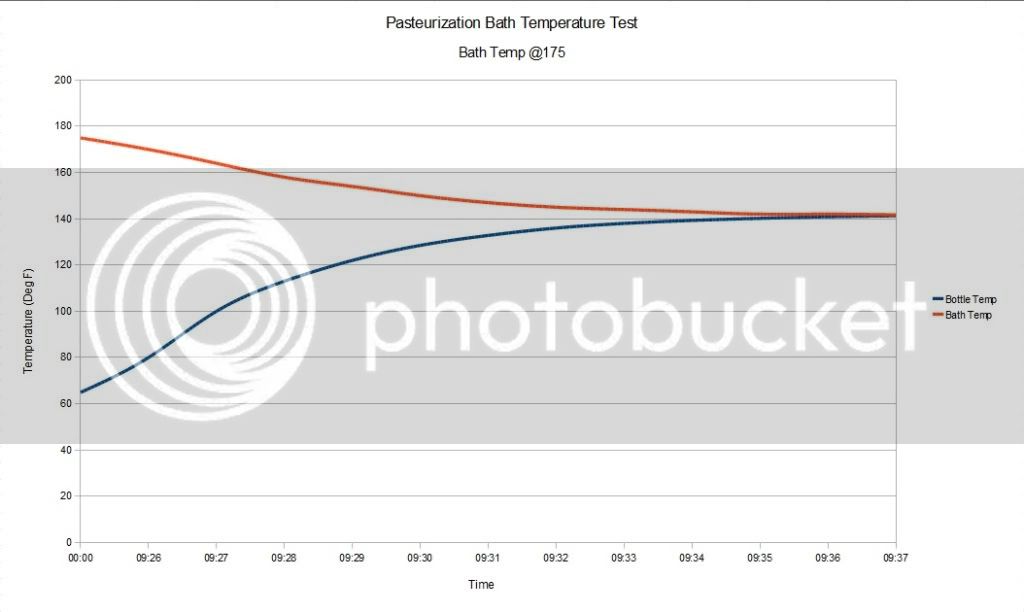

I did 2 tests. 1 test with 165 Degree's and 1 test with 175 Degrees. This was with 12oz Longnecks with water inside instead of beer. I will have to repeat these with cider as I don't have Pressure data, just pasteurization temperature data.

Here is the data for tests with a Sixpack in the bath.

165 Degree Test Data -

175 Degree Test Data -

Summary to follow

I did 2 tests. 1 test with 165 Degree's and 1 test with 175 Degrees. This was with 12oz Longnecks with water inside instead of beer. I will have to repeat these with cider as I don't have Pressure data, just pasteurization temperature data.

Here is the data for tests with a Sixpack in the bath.

165 Degree Test Data -

175 Degree Test Data -

Summary to follow

pimento

Well-Known Member

I forgot to post the yeast pasteurization temperature links earlier.

Advances in Applied Microbiology on google books

The Biological Impact of Flash Pasteurization Over a Wide Temperature Interval

The Handbook of Food Preservation

They all recommend that 60-65C or 140-150F for 30-40 mins should be adequate to kill yeast to log 5.

Lower temps can be used, but the time length becomes a problem.

I've tested my 3 gallon pot by adding 8 12oz capped beer bottles filled with water. I heated the water to 170, removed it from the stove and added the bottles. After 5 mins the water bath temp had dropped to 145F and a test of one bottle showed that the internal water temp was 145F.

I left the bottles in the pot for 10 more mins then removed them and tested 1 bottle every 5 mins. The heat loss from the bottles was very slow, 1-2 degrees every 5 mins.

Including their 10 mins at temp in the waterbath, they remain over 140F for 1/2 and over 130 for 1 hr. I'm confident that is enough time and heat to reduce the yeast to negligible levels.

Advances in Applied Microbiology on google books

The Biological Impact of Flash Pasteurization Over a Wide Temperature Interval

The Handbook of Food Preservation

They all recommend that 60-65C or 140-150F for 30-40 mins should be adequate to kill yeast to log 5.

Lower temps can be used, but the time length becomes a problem.

I've tested my 3 gallon pot by adding 8 12oz capped beer bottles filled with water. I heated the water to 170, removed it from the stove and added the bottles. After 5 mins the water bath temp had dropped to 145F and a test of one bottle showed that the internal water temp was 145F.

I left the bottles in the pot for 10 more mins then removed them and tested 1 bottle every 5 mins. The heat loss from the bottles was very slow, 1-2 degrees every 5 mins.

Including their 10 mins at temp in the waterbath, they remain over 140F for 1/2 and over 130 for 1 hr. I'm confident that is enough time and heat to reduce the yeast to negligible levels.

RukusDM

Well-Known Member

I forgot to post the yeast pasteurization temperature links earlier.

Advances in Applied Microbiology on google books

The Biological Impact of Flash Pasteurization Over a Wide Temperature Interval

The Handbook of Food Preservation

They all recommend that 60-65C or 140-150F for 30-40 mins should be adequate to kill yeast to log 5.

Lower temps can be used, but the time length becomes a problem.

I've tested my 3 gallon pot by adding 8 12oz capped beer bottles filled with water. I heated the water to 170, removed it from the stove and added the bottles. After 5 mins the water bath temp had dropped to 145F and a test of one bottle showed that the internal water temp was 145F.

I left the bottles in the pot for 10 more mins then removed them and tested 1 bottle every 5 mins. The heat loss from the bottles was very slow, 1-2 degrees every 5 mins.

Including their 10 mins at temp in the waterbath, they remain over 140F for 1/2 and over 130 for 1 hr. I'm confident that is enough time and heat to reduce the yeast to negligible levels.

Pimento, very nice summary. I didn't consider the temperature dwell time once removing from the bath. I'm really glad you thought of it.

I'm also happy to see that we have 2 tests that produced the same results. This gives more merit to the data originally posted.

I think that I need to continue tests and plot carbonation curves though. I was a bit concerned to hear that someone had a bottle carb up in 12 hours. Not knowing what that pressure was doesn't help though.

I don't have any cider left to bottle, so I'll have to start a couple of new batches. I'll try a small one with Champagne yeast, as I don't really care for that Strain, and I'll also try a Notty and another S-04 to see if that repeats as well.

I mentioned in my Temperature test post that I would do a summary, I think yours is more than sufficient.

Thanks again, and waiting to see your results

Regards

Doug.

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$27.29 ($13.64 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$39.22 ($39.22 / Count)

Brewer's Best Home Brew Beer Ingredient Kit - 5 Gallon (Mexican Cerveza)

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

No! These results do not reflect each other.

Pimento's cider was dry, with just enough priming sugar added to achieve carbonation. It makes sense that it would take a week to two weeks to carbonate. With less sugar in solution, the yeast have a harder time finding it and consuming it. It's the same principle that causes wine and mead to ferment 90% relatively quick, but often that last 10% takes time, usually in an actual secondary vessel. It's the same reason a beer can ferment out in as little as 3 days, but will take a week or two weeks to carbonate because the yeast has settled, there are fewer cells in the bottles, and less sugar added back in.

RukusDM's cider was sweet.... what, like 1.012... and wasn't cold crashed to drop cells, and then even more sugar added to prime. Just because you both had similar results in the time it took to carbonate does not mean you've replicated each other's experiments. I am still having a hard time wrapping my mind around those results. I urge you to repeat this experiment before you draw any conclusions. I once bottled beer with a filthy tube that I didn't sanitize, I also used my mouth to create the siphon, and didn't use mouthwash first. I got no infection. That does not mean it's acceptable practice.

I don't want to crap on your work, I enjoy and appreciate it, especially the water bath temp/time curves.

I think you need to do more research before you draw any conclusions. And as a pessimist, I believe you'll find too many variables that you can't control that will swing the results every time.

Pimento's cider was dry, with just enough priming sugar added to achieve carbonation. It makes sense that it would take a week to two weeks to carbonate. With less sugar in solution, the yeast have a harder time finding it and consuming it. It's the same principle that causes wine and mead to ferment 90% relatively quick, but often that last 10% takes time, usually in an actual secondary vessel. It's the same reason a beer can ferment out in as little as 3 days, but will take a week or two weeks to carbonate because the yeast has settled, there are fewer cells in the bottles, and less sugar added back in.

RukusDM's cider was sweet.... what, like 1.012... and wasn't cold crashed to drop cells, and then even more sugar added to prime. Just because you both had similar results in the time it took to carbonate does not mean you've replicated each other's experiments. I am still having a hard time wrapping my mind around those results. I urge you to repeat this experiment before you draw any conclusions. I once bottled beer with a filthy tube that I didn't sanitize, I also used my mouth to create the siphon, and didn't use mouthwash first. I got no infection. That does not mean it's acceptable practice.

I don't want to crap on your work, I enjoy and appreciate it, especially the water bath temp/time curves.

I think you need to do more research before you draw any conclusions. And as a pessimist, I believe you'll find too many variables that you can't control that will swing the results every time.

RukusDM

Well-Known Member

No! These results do not reflect each other.

Pimento's cider was dry, with just enough priming sugar added to achieve carbonation. It makes sense that it would take a week to two weeks to carbonate. With less sugar in solution, the yeast have a harder time finding it and consuming it. It's the same principle that causes wine and mead to ferment 90% relatively quick, but often that last 10% takes time, usually in an actual secondary vessel. It's the same reason a beer can ferment out in as little as 3 days, but will take a week or two weeks to carbonate because the yeast has settled, there are fewer cells in the bottles, and less sugar added back in.

RukusDM's cider was sweet.... what, like 1.012... and wasn't cold crashed to drop cells, and then even more sugar added to prime. Just because you both had similar results in the time it took to carbonate does not mean you've replicated each other's experiments. I am still having a hard time wrapping my mind around those results. I urge you to repeat this experiment before you draw any conclusions. I once bottled beer with a filthy tube that I didn't sanitize, I also used my mouth to create the siphon, and didn't use mouthwash first. I got no infection. That does not mean it's acceptable practice.

I don't want to crap on your work, I enjoy and appreciate it, especially the water bath temp/time curves.

I think you need to do more research before you draw any conclusions. And as a pessimist, I believe you'll find too many variables that you can't control that will swing the results every time.

Well its true the testing isn't complete, however I didn't make these numbers up. Perhaps you could do some testing to verify?

RukusDM

Well-Known Member

What was the starting time in each of your latest tables? 8:47 and 9:25?

Yes, those were the times.

RukusDM

Well-Known Member

No! These results do not reflect each other.

Pimento's cider was dry, with just enough priming sugar added to achieve carbonation. It makes sense that it would take a week to two weeks to carbonate. With less sugar in solution, the yeast have a harder time finding it and consuming it. It's the same principle that causes wine and mead to ferment 90% relatively quick, but often that last 10% takes time, usually in an actual secondary vessel. It's the same reason a beer can ferment out in as little as 3 days, but will take a week or two weeks to carbonate because the yeast has settled, there are fewer cells in the bottles, and less sugar added back in.

RukusDM's cider was sweet.... what, like 1.012... and wasn't cold crashed to drop cells, and then even more sugar added to prime. Just because you both had similar results in the time it took to carbonate does not mean you've replicated each other's experiments. I am still having a hard time wrapping my mind around those results. I urge you to repeat this experiment before you draw any conclusions. I once bottled beer with a filthy tube that I didn't sanitize, I also used my mouth to create the siphon, and didn't use mouthwash first. I got no infection. That does not mean it's acceptable practice.

I don't want to crap on your work, I enjoy and appreciate it, especially the water bath temp/time curves.

I think you need to do more research before you draw any conclusions. And as a pessimist, I believe you'll find too many variables that you can't control that will swing the results every time.

How many of the variables are changed when you don't do the testing we have done and bottle carb anyway?

Nothing has changed in the pasteurization method that Pappers has put together other than how we build in a safety by measuring pressure, and use lower temperatures to complete the pasteurization.

I think if you are going to do Pasteurization, you should have a method to measure pressure or you will most defiantly run the risk of popping some.

You think this is less safe than current methods?

Well its true the testing isn't complete, however I didn't make these numbers up. Perhaps you could do some testing to verify?

I didn't say you made up the numbers. Relax.

I have tested, but didn't plot the data. They were mental notes. I outlined my last gallon of cider results on page one. They are very distant from your results. You chose to ignore those, but accept pimentos. Are you doing what scientists often do, unintentionally; accepting results similar to yours while ignoring results that contradict your own?

RukusDM

Well-Known Member

I didn't say you made up the numbers. Relax.

I have tested, but didn't plot the data. They were mental notes. I outlined my last gallon of cider results on page one. They are very distant from your results. You chose to ignore those, but accept pimentos. Are you doing what scientists often do, unintentionally; accepting results similar to yours while ignoring results that contradict your own?

If you would read more carefully, you would find I Said tests are not complete. I mentioned someone having a event where a bottle carbed in 12 hours, and I was concerned.

RukusDM

Well-Known Member

I got my hands on 2 more gauges in the 0 - 100 Psi. I'll be able to do several tests at a time. I should be able to do a Champagne, Notty and another S-04 Carbonation all at the same time.

I have to get 6 Gallons of cider fermenting with the different yeasts first. I'll try and stop after work Monday to get the stuff.

I will try and get a very aggressive carbonation going with a but load of sugar to see what that produces with Champagne yeast, unless someone has a more aggressive one I should try.

I may elect to can the S-04 and go with the S-05 if I can find it. I havn't seen that at the local brew shop.

That would help reproduce what Fletch had seen in his test. Perhaps S-05 and a but-load of sugar 1.020 at SG finish to see what happens pressure wise during carbing.

Fletch, could you give me a rough recipe you used to produce that batch of cider so I can get as close as I can?

I have to get 6 Gallons of cider fermenting with the different yeasts first. I'll try and stop after work Monday to get the stuff.

I will try and get a very aggressive carbonation going with a but load of sugar to see what that produces with Champagne yeast, unless someone has a more aggressive one I should try.

I may elect to can the S-04 and go with the S-05 if I can find it. I havn't seen that at the local brew shop.

That would help reproduce what Fletch had seen in his test. Perhaps S-05 and a but-load of sugar 1.020 at SG finish to see what happens pressure wise during carbing.

Fletch, could you give me a rough recipe you used to produce that batch of cider so I can get as close as I can?

pimento

Well-Known Member

No! These results do not reflect each other.

Pimento's cider was dry, with just enough priming sugar added to achieve carbonation. It makes sense that it would take a week to two weeks to carbonate. With less sugar in solution, the yeast have a harder time finding it and consuming it. It's the same principle that causes wine and mead to ferment 90% relatively quick, but often that last 10% takes time, usually in an actual secondary vessel. It's the same reason a beer can ferment out in as little as 3 days, but will take a week or two weeks to carbonate because the yeast has settled, there are fewer cells in the bottles, and less sugar added back in.

RukusDM's cider was sweet.... what, like 1.012... and wasn't cold crashed to drop cells, and then even more sugar added to prime. Just because you both had similar results in the time it took to carbonate does not mean you've replicated each other's experiments. I am still having a hard time wrapping my mind around those results. I urge you to repeat this experiment before you draw any conclusions. I once bottled beer with a filthy tube that I didn't sanitize, I also used my mouth to create the siphon, and didn't use mouthwash first. I got no infection. That does not mean it's acceptable practice.

I don't want to crap on your work, I enjoy and appreciate it, especially the water bath temp/time curves.

I think you need to do more research before you draw any conclusions. And as a pessimist, I believe you'll find too many variables that you can't control that will swing the results every time.

If you'd bothered to read my full post you'd see that only half my graff was done dry, the other half was backsweetened to a level similar to RukusDMs.

I have just now finished pasteurizing the whole batch and there was very little difference in carbonation between the two.

Your theory that wine and mead slows down in the last 10% because of less sugar is entirely unfounded and honestly, I don't think you know what you are talking about.

Wines and meads slow down in the later stages because the nutrients get used up. It has nothing to do with there being less sugar. Re-read Cvillekevins posts and pay attention to when he talks about keeving and using low-nitrogen apples. Yeast in the absence of nutrients, particularly nitrogen will slow down and eventually go dormant.

As far as the cider I just pasteurized, both the dry and the sweet were somewhat over carbonated and yes, I think I got lucky not having and bottles break. Next time I will probably pasteurize at 17-18psi.

That is the point of RukusDMs post, he hasn't drawn any conclusions. He simply posted his findings on his experiments. It's an attempt to find a reliable, repeatable pressure at which bottle pasteurization can be done.

RukusDM

Well-Known Member

I must say I'm a bit confused as your bottles having more carbonation than mine with the same pressures. I did not use the higher temperature though, I used 160, and they have a nice initial head but not allot of carb, but something I would not mind having every day.

Any chance they weren't cooled down to normal fridge temps before you opened?

Thinking....hmmmf.

Any chance they weren't cooled down to normal fridge temps before you opened?

Thinking....hmmmf.

RukusDM

Well-Known Member

Is graff something that might be more on the acidic side or more toward the base side of the ph scale?

Mine was more on the acidic side as I had added Citric Acid to tart the stuff up prior to bottling. hmmm

Mine was more on the acidic side as I had added Citric Acid to tart the stuff up prior to bottling. hmmm

pimento

Well-Known Member

I must say I'm a bit confused as your bottles having more carbonation than mine with the same pressures. I did not use the higher temperature though, I used 160, and they have a nice initial head but not allot of carb, but something I would not mind having every day.

Any chance they weren't cooled down to normal fridge temps before you opened?

Thinking....hmmmf.

They were room temp, before pasteurizing. I expect they will get less foamy once refrigerated, but still a higher carb than i'd like.

I'm bottling another cider next week, so we'll see how that stacks up.

RukusDM

Well-Known Member

I just recalled something. I took a sixer of this stuff over to my neigbors last week to have a couple with him.

We drank a couple...They were chilled. The last one he opened had a mild gusher and lost a oz or so of cider. We had just opened 4 with nothing like this. We drank these prior to Pasteurization, as they were still in the bottle conditioning stage.

I took a look at his bottle and it had more yeast on the bottom than I had seen with any of the bottles. Its possible when I bottled the last few from the bucket, I got some lees from the bottom in them.

We drank a couple...They were chilled. The last one he opened had a mild gusher and lost a oz or so of cider. We had just opened 4 with nothing like this. We drank these prior to Pasteurization, as they were still in the bottle conditioning stage.

I took a look at his bottle and it had more yeast on the bottom than I had seen with any of the bottles. Its possible when I bottled the last few from the bucket, I got some lees from the bottom in them.

Your theory that wine and mead slows down in the last 10% because of less sugar is entirely unfounded and honestly, I don't think you know what you are talking about.

Wines and meads slow down in the later stages because the nutrients get used up. It has nothing to do with there being less sugar. Re-read Cvillekevins posts and pay attention to when he talks about keeving and using low-nitrogen apples. Yeast in the absence of nutrients, particularly nitrogen will slow down and eventually go dormant.

Unfounded? This is from the Mead Sticky by hightest.. his Staggered Nutrient Addition link. It contradicts you. Should he re-read Cville's sticky too?

http://home.comcast.net/~mzapx1/FAQ/SNAddition.pdf

pimento

Well-Known Member

Unfounded? This is from the Mead Sticky by hightest.. his Staggered Nutrient Addition link. It contradicts you. Should he re-read Cville's sticky too?

http://home.comcast.net/~mzapx1/FAQ/SNAddition.pdf

Did you even bother to read your own link?

Can you point to me where hightest mentions mead fermentation slowing down because of lower sugar levels in the last 10%?

Notice that he never says that.

In fact he's saying the same thing I did, that yeast with to little nutrients will slow down later in fermentation.

His entire stepped nutrient additions are planned to stop the slow down.

Apparently you're having comprehension issues with this paragraph

The nutrient quantities were changed based on conversations with Dr. Clayton Cone wherein I learned that he recommended the bulk of the nutrients be added before 30% sugar depletion - the yeast are usually well into their stationary phase at 50% sugar depletion and cannot utilize the nutrients as well as they can before 30% depletion. As such, the NAS (second revision) now adds 85% of the nutrient nitrogen before 30% sugar depletion.

He is saying that the yeast do no utilize the nutrients well after 30% sugar depletion, not that lack of sugar is the cause.

Nutrients applied before the 30% depletion help the yeast build healthy cells, budd and process sugar so they can remain healthy later in the fermentation process.

To put it simply nutrients early on make for stronger yeast cells which don't slow down later in fermentation.

This doesn't contradict what I said at all,

Wines and meads slow down in the later stages because the nutrients get used up. It has nothing to do with there being less sugar. Re-read Cvillekevins posts and pay attention to when he talks about keeving and using low-nitrogen apples. Yeast in the absence of nutrients, particularly nitrogen will slow down and eventually go dormant.

The nutrients get used up, the cells are weaker and eventually slow down.

Sorry for the derail RukusDM.

pimento

Well-Known Member

I just recalled something. I took a sixer of this stuff over to my neigbors last week to have a couple with him.

We drank a couple...They were chilled. The last one he opened had a mild gusher and lost a oz or so of cider. We had just opened 4 with nothing like this. We drank these prior to Pasteurization, as they were still in the bottle conditioning stage.

I took a look at his bottle and it had more yeast on the bottom than I had seen with any of the bottles. Its possible when I bottled the last few from the bucket, I got some lees from the bottom in them.

I just cracked open my gauged pop bottle and it had less carbonation than the rest.

It may be that when I split the batches the priming sugar wasn't mixed well and that bottle got a bit less.

I won't be splitting this coming batch, so we'll see how it compares.

No, you said yeast slow down because they run out of nutrients.

The fact is that yeast can't use the nutrients after the 1/2 (or 2/3, there is debate) sugar break.

The last 10% of fermentation is well after both the 1/2 and 2/3 sugar break.

The OP asked for opinions on his/her data, I gave my opinion, and you don't like it. Fine. If I keep participating in this thread, it's going to get locked and sent to a place where the plebians can't enjoy it. I want plebians to enjoy it. Have fun with the rest of this. I'm done.

The fact is that yeast can't use the nutrients after the 1/2 (or 2/3, there is debate) sugar break.

The last 10% of fermentation is well after both the 1/2 and 2/3 sugar break.

The OP asked for opinions on his/her data, I gave my opinion, and you don't like it. Fine. If I keep participating in this thread, it's going to get locked and sent to a place where the plebians can't enjoy it. I want plebians to enjoy it. Have fun with the rest of this. I'm done.

RukusDM

Well-Known Member

I just cracked open my gauged pop bottle and it had less carbonation than the rest.

It may be that when I split the batches the priming sugar wasn't mixed well and that bottle got a bit less.

I won't be splitting this coming batch, so we'll see how it compares.

That might explain the overcarb on the others but having the same pressure as I had.

RukusDM

Well-Known Member

To be clear, are you adding priming sugar to a dry, cold crashed, racked cider?

Because I recently cold crashed a fermenting cider at 1.020 ... bottled... and tested 12 hours later and had adequate carbonation. If noobs read this, and think it will take two weeks for their sweet cider to carbonate in the bottle before pasteurizing, someone is going to die. Can you give more info, preferably edited into your OP, about the cider going into your experiment?

Fletch, as I mentioned in the PM, I found some S-05 yeast. Thanks for passing your recipe on to me. I don't have a 1 Gallon ferment jug, however I do have a 3 Liter, I should be able to produce your initial conditions. I don't use camp-den, but I'll get some this week and put that in the batch as well.

This should put me in the position of getting close to your original situation. Do you know roughly what temperature you fermented at?

I'll stop it at 1.020 and put into my pressure bottle and also regular beer bottles and condition to see what the pressure curve is. Also I think you already provided, however what was your bottle conditioning temperature. Roughly that is.

Regards

Doug

Rukus, your PM box must be full.

Ferm temp low 60's, no exact number. Campden was only added 24 hours prior because it was raw and for all I know this lady accidentally ground up one of the stray cats in the cider press. Bottle conditioned is 72, almost exactly, kitchen counter temp.

Thought #1:

I didn't use a pressure gauge. I went by bubbles and foam in the glass when poured. 12 hours, "carbonated". It occurred to me just now, there is already alot of CO2 dissolved in the cider from fermentation... I just degassed another batch by gently swirling the carboy and this occurred to me. Because there was so much CO2 already in the liquid, a long wait for the bottle to carb wasn't necessary.

Thought #2:

It went from 1.056 to 1.020 in about 6 days. That equals about 6 gravity points a day, or 3 gravity points every 12 hours. My understanding, I've read somewhere, it's less than 1 gravity point that is necessary to carbonate a beer. Doing a quick calculation, a standard 5 oz of priming sugar in a 5 gallon batch of beer only bumps the gravity by 0.001.

Ferm temp low 60's, no exact number. Campden was only added 24 hours prior because it was raw and for all I know this lady accidentally ground up one of the stray cats in the cider press. Bottle conditioned is 72, almost exactly, kitchen counter temp.

Thought #1:

I didn't use a pressure gauge. I went by bubbles and foam in the glass when poured. 12 hours, "carbonated". It occurred to me just now, there is already alot of CO2 dissolved in the cider from fermentation... I just degassed another batch by gently swirling the carboy and this occurred to me. Because there was so much CO2 already in the liquid, a long wait for the bottle to carb wasn't necessary.

Thought #2:

It went from 1.056 to 1.020 in about 6 days. That equals about 6 gravity points a day, or 3 gravity points every 12 hours. My understanding, I've read somewhere, it's less than 1 gravity point that is necessary to carbonate a beer. Doing a quick calculation, a standard 5 oz of priming sugar in a 5 gallon batch of beer only bumps the gravity by 0.001.

RukusDM

Well-Known Member

Rukus, your PM box must be full.

Ferm temp low 60's, no exact number. Campden was only added 24 hours prior because it was raw and for all I know this lady accidentally ground up one of the stray cats in the cider press. Bottle conditioned is 72, almost exactly, kitchen counter temp.

Thought #1:

I didn't use a pressure gauge. I went by bubbles and foam in the glass when poured. 12 hours, "carbonated". It occurred to me just now, there is already alot of CO2 dissolved in the cider from fermentation... I just degassed another batch by gently swirling the carboy and this occurred to me. Because there was so much CO2 already in the liquid, a long wait for the bottle to carb wasn't necessary.

Thought #2:

It went from 1.056 to 1.020 in about 6 days. That equals about 6 gravity points a day, or 3 gravity points every 12 hours. My understanding, I've read somewhere, it's less than 1 gravity point that is necessary to carbonate a beer. Doing a quick calculation, a standard 5 oz of priming sugar in a 5 gallon batch of beer only bumps the gravity by 0.001.

strange....there were just 2....I get five. hmmf. I deleted everything but your recipe. Should be ok now

RukusDM

Well-Known Member

Rukus, your PM box must be full.

Ferm temp low 60's, no exact number. Campden was only added 24 hours prior because it was raw and for all I know this lady accidentally ground up one of the stray cats in the cider press. Bottle conditioned is 72, almost exactly, kitchen counter temp.

Thought #1:

I didn't use a pressure gauge. I went by bubbles and foam in the glass when poured. 12 hours, "carbonated". It occurred to me just now, there is already alot of CO2 dissolved in the cider from fermentation... I just degassed another batch by gently swirling the carboy and this occurred to me. Because there was so much CO2 already in the liquid, a long wait for the bottle to carb wasn't necessary.

Thought #2:

It went from 1.056 to 1.020 in about 6 days. That equals about 6 gravity points a day, or 3 gravity points every 12 hours. My understanding, I've read somewhere, it's less than 1 gravity point that is necessary to carbonate a beer. Doing a quick calculation, a standard 5 oz of priming sugar in a 5 gallon batch of beer only bumps the gravity by 0.001.

Fletch, I believe you have the answer. That is a great thought. Cider already carbed up prior to bottle. I never gave that a thought. Good one.

Think I should still continue, or do you think that was it? Of course I cant see what you did just now, but it sure makes sense.

Edit: Also very good idea on thought #2 as well

Similar threads

Latest posts

-

-

-

-

-

-

-

I just poured 42 bottles of HB Dunkelweizen down the drain

- Latest: Hoochin'Fool

-