I appreciate BB's plug, though I think crediting me for only the TC tee isn't exactly telling the whole story. I did not receive any notice, but they certainly weren't obligated to. I put the information on here freely for the advancement of the community. If they want to package the kit and make a a few bucks on it - it's all good.

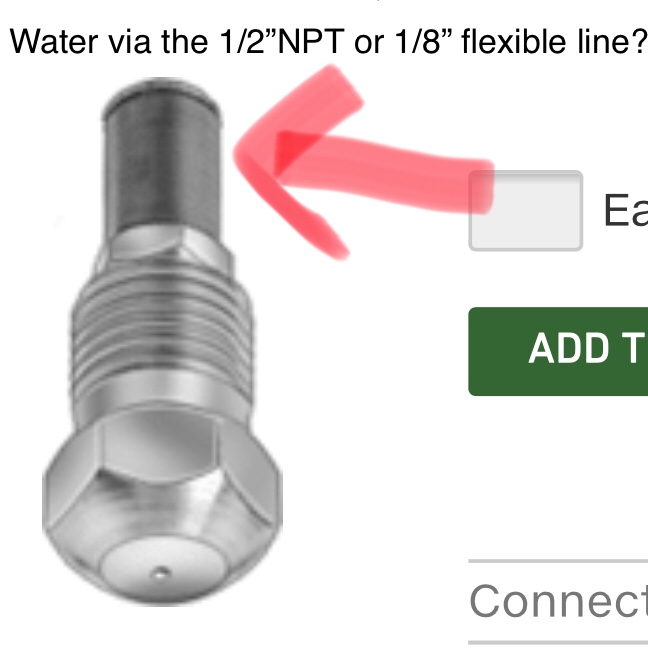

In any event, here is a parts list should anyone want to piece this up themselves. This uses 2" TC, but you could perhaps go smaller as BB is. Maybe 1.5" TC would be acceptable and save a few dollars - I just didn't test that so cannot vouch for it. I used different parts in mine but I think this would be how I would do it if starting over. This will yield a 1/2" NPT female connection for you to add whatever fitting you need to for incoming water. It mounts via a 2" TC flange that needs to be soldered on, welded, or JB welded on for those kettles that don't have a TC port there. Other methods for connected can certainly be explored. For example, BrewHardware sells a 1.5" weld-less TC port that could work if going 1.5" TC.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)