so now we have a TC port in the lid, can anyone see why we couldnt use this to mount a Whirlpool/return line to the BK? So flame out remove Steam Slayer and mount a return fitting. I would use this for re-circulation through the CFC to bk for a few minutes to sterilize.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boil kettle condenser - no overhead ventilation needed

- Thread starter BrunDog

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ancientmariner52

Well-Known Member

Probably not as good as reflectix (sp?) or similar materials. Since my concerns were more avoiding contact burns and being machine washable than thermal performance, I believe it will serve.How well do you think it will insulate?

What I really wanted was wooden slats and brass bands like an 1830s locomotive boiler, but I'm much too lazy to actually build it.

Once I actually brew with this rig I'll report back. I intend to set the HLT and kettle on pieces of blue foam insulation board. I don't THINK it will quite melt. I'll let you know.

Additional: forgot to mention, we used three layers of the pre-quilted fabric.

Last edited:

ancientmariner52

Well-Known Member

Sounds practical to me. If suitable fittings aren't available off the shelf, it wouldn't be too difficult to drill a TC blank to fit a 1/2 NPT weldless bullhead fitting. Probably a dozen better ways, just have to think about it.so now we have a TC port in the lid, can anyone see why we couldnt use this to mount a Whirlpool/return line to the BK? So flame out remove Steam Slayer and mount a return fitting. I would use this for re-circulation through the CFC to bk for a few minutes to sterilize.

Probably not as good as reflectix (sp?) or similar materials. Since my concerns were more avoiding contact burns and being machine washable than thermal performance, I believe it will serve.

Additional: forgot to mention, we used three layers of the pre-quilted fabric.

I'd bet the other way, that it's better than reflectix, at least a single layer of reflectix. I have a layer of reflectix around my kettle mash tun, and while it certainly helps, if I were to choose, I'd choose yours.

ancientmariner52

Well-Known Member

You may well be right. I used some relectix and duct tape on a Charlie Papazian-style mash tun years ago. It worked well enough, but to be honest I just hated the appearance of it. Kind of ragged and unfinished looking, I suppose.I'd bet the other way, that it's better than reflectix, at least a single layer of reflectix. I have a layer of reflectix around my kettle mash tun, and while it certainly helps, if I were to choose, I'd choose yours.

d3track

Are you sure about that?

I asked my daughter to stitch up an insulated wrapper for my boil kettle. I couldn't find black quilted fabric to match the HLT, so I bought white. This is what she presented to me just now.View attachment 599053

I would have left it classy

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid MFL)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

Gotta keep that lace on there. That is classic!!!I asked my daughter to stitch up an insulated wrapper for my boil kettle. I couldn't find black quilted fabric to match the HLT, so I bought white. This is what she presented to me just now.View attachment 599053

ingchr1

Well-Known Member

I recirc while mashing, then swap it out with the 90 for my condenser.so now we have a TC port in the lid, can anyone see why we couldnt use this to mount a Whirlpool/return line to the BK? So flame out remove Steam Slayer and mount a return fitting. I would use this for re-circulation through the CFC to bk for a few minutes to sterilize.

I recirc while mashing, then swap it out with the 90 for my condenser.

View attachment 599270

View attachment 599271

View attachment 599272

This is one of the times this site really shines. I have a locline manifold as well, and had it connected to a 1/2" NPT nipple on the inside of my kettle; after seeing how you used camlocks on yours, I realized I could do the same, utilizing a couple spare parts I had lying around.

Before I had to thread it on and off. Now, easy to connect, easy to remove.

It will definitely perform much better if he keeps the lace on.How well do you think it will insulate?

I recirc while mashing, then swap it out with the 90 for my condenser.

View attachment 599270

View attachment 599271

View attachment 599272

That really is very cool. I have lockline on order and will try this out when it arrives

What are you guys using for containing your hops during the boil, while using a lid on your BK? I currently use a hop spider from Utah Biodiesel, and it hangs on the side of the BK during the boil. This idea really intrigues me. And, I wouldn't have to drill a large hole to the outside for my vent hood.

Thanks

Thanks

What are you guys using for containing your hops during the boil, while using a lid on your BK? I currently use a hop spider from Utah Biodiesel, and it hangs on the side of the BK during the boil. This idea really intrigues me. And, I wouldn't have to drill a large hole to the outside for my vent hood.

Thanks

I'm just tossing them in. I'm going to do some long-term testing of Yakima Valley hop shots, which don't have any hop trub. I did hops in a bag, hops in a spider, hops in a screened cylinder that hangs off the side--and I was never happy with the utilization I got them them.

Once I get the Hop Shot thing dialed in, assuming I do, then most of the late addition hops will end up in a hop cone after whirlpooling.

I'm not sure you can really hang anything off the side of the kettle and get a good enough "seal" for the steam catcher to work--though in fairness, I haven't actually tried that. I always assumed it wouldn't work properly. Maybe I should give it a try.

[...]I'm not sure you can really hang anything off the side of the kettle and get a good enough "seal" for the steam catcher to work--though in fairness, I haven't actually tried that.[...]

You're suspicion is on point - I had a spider with the thin over-hanging straps and steam would definitely emit through the resulting lid gap.

An experiment in setting the spider on the kettle floor resulted in a matching scorch ("Don't Do That") so that's out.

Years ago I had high hopes for the original Hop Stopper that were fairly dashed on the first outing. I wonder if the latest incarnation is much better...

Cheers!

I'm with mongoose33; I no longer put my boil or WP hops in anything. However, somewhere way back in this thread someone discussed mounting magnets to their hop spider to hold it to the side. Just search 'magnets' in this thread.

Years ago I had high hopes for the original Hop Stopper that were fairly dashed on the first outing. I wonder if the latest incarnation is much better...

Cheers!

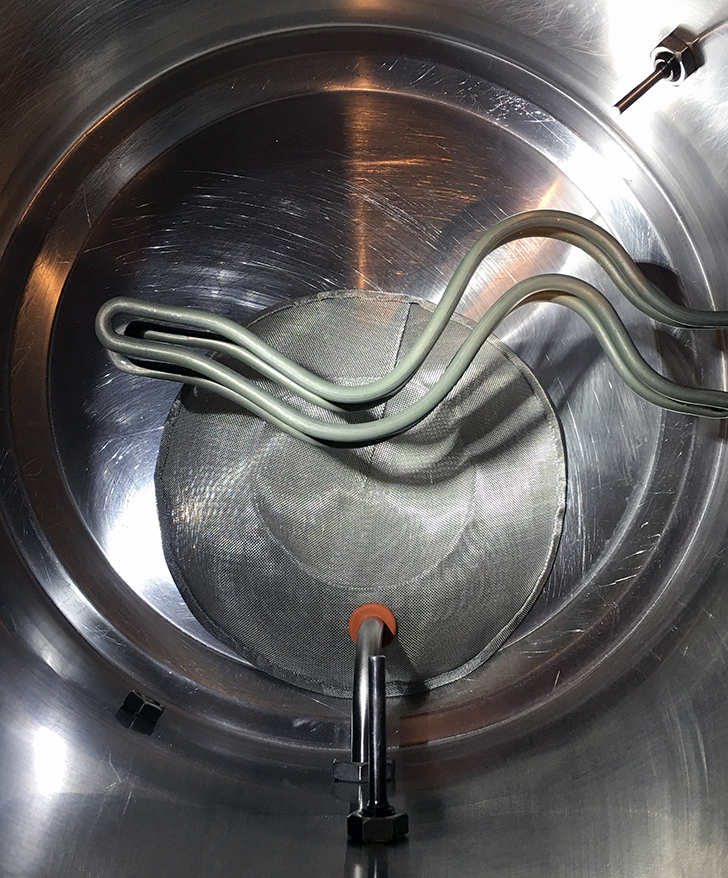

That looks...interesting....but I can't see how it would work in a kettle with an electric heating element. Like so:

Am I missing something with how it's used?

so now we have a TC port in the lid, can anyone see why we couldnt use this to mount a Whirlpool/return line to the BK? So flame out remove Steam Slayer and mount a return fitting. I would use this for re-circulation through the CFC to bk for a few minutes to sterilize.

Sure, you just use something like this https://www.norcalbrewingsolutions.com/store/1.5-Inch-Tri-Clover-x-4-Inch-NPT-Nipple-Connect.html

mount your whirlpool arm on the inside and a quick disconnect of choice on the outside.

rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

The last time I brewed (an oatmeal stout - so not hoppy at all), I put the hops in a fine mesh bag and let the opening of the bag hang over the top of the kettle. I flattened out the bag as much as I could and put the cover on the kettle to hold the bag in place. It sealed just OK, not perfect. I suppose I could have tied off the end of the mesh bag and just thrown it in the kettle when boiling and probably not seen any difference.What are you guys using for containing your hops during the boil, while using a lid on your BK? I currently use a hop spider from Utah Biodiesel, and it hangs on the side of the BK during the boil. This idea really intrigues me. And, I wouldn't have to drill a large hole to the outside for my vent hood.

Thanks

In the future, I may make or buy a hop spider/basket and modify it to be held with a magnet outside the kettle. Or, just continue to use the mesh bag, but tied off and thrown in - that would be much easier, and likely no difference in effectiveness or final result.

I do like keeping the hop sludge out of the process during and after boiling.

I absolutely love this idea and am glad that I stumbled upon it before buying a vent hood and fan for my garage brewery.

I'm not sure if this has been asked already (since we're at 23 pages so far and I don't have time to read them all at the moment), but why can't we achieve the same thing with a large coil of copper tubing, like an old immersion chiller, which is sitting on top of a box fan or some other air powered cooling source?

I'm not sure if this has been asked already (since we're at 23 pages so far and I don't have time to read them all at the moment), but why can't we achieve the same thing with a large coil of copper tubing, like an old immersion chiller, which is sitting on top of a box fan or some other air powered cooling source?

The last time I brewed (an oatmeal stout - so not hoppy at all), I put the hops in a fine mesh bag and let the opening of the bag hang over the top of the kettle. I flattened out the bag as much as I could and put the cover on the kettle to hold the bag in place. It sealed just OK, not perfect. I suppose I could have tied off the end of the mesh bag and just thrown it in the kettle when boiling and probably not seen any difference.

In the future, I may make or buy a hop spider/basket and modify it to be held with a magnet outside the kettle. Or, just continue to use the mesh bag, but tied off and thrown in - that would be much easier, and likely no difference in effectiveness or final result.

I do like keeping the hop sludge out of the process during and after boiling.

I was honestly not too happy with the hop utilization from the nylon mesh basket I first used, then I went to a hop spider thinking the extra space would be nice, then now finally to the SS Mesh Hop spider....I'm still not too happy with it. So, I have been considering going to one of the BIAB baskets Utah Biodiesel sells. Then, the hops could do whatever they wanted during the boil. My other thought was doing a whirlpool, during flame out since I'm planning to get a pump.

I would be much more happy to deal with hop trub, then having to cut in hole in my perfectly good wall(with brand new exterior siding) for a vent.

Are you referring to using a basket as large as the entire diameter of your kettle? I too was thinking of doing that a couple of years ago, but have been told by many experts that the wort inside a basket like that will never boil. I don't completely understand the science, but this came from people in the industry that I trust.I was honestly not too happy with the hop utilization from the nylon mesh basket I first used, then I went to a hop spider thinking the extra space would be nice, then now finally to the SS Mesh Hop spider....I'm still not too happy with it. So, I have been considering going to one of the BIAB baskets Utah Biodiesel sells. Then, the hops could do whatever they wanted during the boil. My other thought was doing a whirlpool, during flame out since I'm planning to get a pump.

I would be much more happy to deal with hop trub, then having to cut in hole in my perfectly good wall(with brand new exterior siding) for a vent.Plus, I live in a somewhat rural community, and the more holes in my exterior, the more likely I find intruders.

My guess, you'd never be able to condense all the steam because you couldn't transfer enough BTUs given the limitations on heat transfer (air on outside, slow moving steam on the inside that's probably in the laminar flow regime). Now if you had something more like a radiator with finned tubing, you might be on to something.I absolutely love this idea and am glad that I stumbled upon it before buying a vent hood and fan for my garage brewery.

I'm not sure if this has been asked already (since we're at 23 pages so far and I don't have time to read them all at the moment), but why can't we achieve the same thing with a large coil of copper tubing, like an old immersion chiller, which is sitting on top of a box fan or some other air powered cooling source?

I could see other questions around how to support a large copper coil off the side of the kettle.

Gameface

Well-Known Member

I brewed with my steam slayer over the weekend. Worked very well!

In fact, it worked too well in that I could maintain a vigorous boil at 50% power (PID in manual mode) and I was a bit slow to go that low. But I didn't even have a real boil-over, the steam slayer sucked everything out. Bottom of the lid had a nice layer of hops on it after the brew and I'm guessing I didn't get the hop utilization I was expecting with all the hops left on the walls of the kettle and the lid, but this is a Scottish Export Ale and my IBUs were on the high side in the recipe so I'm sure it'll be fine.

In fact, it worked too well in that I could maintain a vigorous boil at 50% power (PID in manual mode) and I was a bit slow to go that low. But I didn't even have a real boil-over, the steam slayer sucked everything out. Bottom of the lid had a nice layer of hops on it after the brew and I'm guessing I didn't get the hop utilization I was expecting with all the hops left on the walls of the kettle and the lid, but this is a Scottish Export Ale and my IBUs were on the high side in the recipe so I'm sure it'll be fine.

I brewed with my steam slayer over the weekend. Worked very well!

In fact, it worked too well in that I could maintain a vigorous boil at 50% power (PID in manual mode) and I was a bit slow to go that low. But I didn't even have a real boil-over, the steam slayer sucked everything out. Bottom of the lid had a nice layer of hops on it after the brew and I'm guessing I didn't get the hop utilization I was expecting with all the hops left on the walls of the kettle and the lid, but this is a Scottish Export Ale and my IBUs were on the high side in the recipe so I'm sure it'll be fine.

Don't feel like you're the first brewer to which this has happened.

But yeah, it sure works, and works well.

That looks...interesting....but I can't see how it would work in a kettle with an electric heating element. [...]Am I missing something with how it's used?

The link was to a lengthy web page that has a bunch of pics showing the standard V2 Stopper under a ULD ripple element.

Like this:

So I guess it depends on high up the element is mounted...

Cheers!

Are you referring to using a basket as large as the entire diameter of your kettle? I too was thinking of doing that a couple of years ago, but have been told by many experts that the wort inside a basket like that will never boil. I don't completely understand the science, but this came from people in the industry that I trust.

Very interesting. It also doesn't make sense to me that it wouldn't boil. I guess is it because of how fine the SS mesh is on the basket? Because every dude in the south boiling crayfish would have a problem with their basket with this theory.

I guess I could ask the Utah BioDiesel guys if they've boiled with their basket in the kettle.

I'm one of those dudes in the south! Those crawfish baskets have large holes punched in them. But like I said, I don't completely understand the science. I recall it does have something to do with the bubbles produced by boiling. Just trying to give you fair warning to do your research before investing in one of those baskets.Very interesting. It also doesn't make sense to me that it wouldn't boil. I guess is it because of how fine the SS mesh is on the basket? Because every dude in the south boiling crayfish would have a problem with their basket with this theory.

I guess I could ask the Utah BioDiesel guys if they've boiled with their basket in the kettle.

I could see other questions around how to support a large copper coil off the side of the kettle.

The coil wouldn't need to be supported if the coil input was long enough. I'm just trying to avoid the requirement for running water. Don't get me wrong, I'd use the excess water to clean up afterwards. It is just that extra bit of plumbing complexity being added to an already complex process. Whenever I describe how my brewery works to the non-initiated, their eyes will always glaze over about halfway through

ancientmariner52

Well-Known Member

I'm thinking that circulation of the boiling water would be the issue. Large holes, say 1/4" or bigger, will allow heated water to rise, so that colder, denser, water can reach the heating surface. A solid or fine mesh bottom basket, not so much. In the worst case, a steam bubble forms and the basket hops up and down, and the wort is scorched, on account of lack of circulation.I'm one of those dudes in the south! Those crawfish baskets have large holes punched in them. But like I said, I don't completely understand the science. I recall it does have something to do with the bubbles produced by boiling. Just trying to give you fair warning to do your research before investing in one of those baskets.

Similar threads

- Replies

- 2

- Views

- 913

- Replies

- 1

- Views

- 548

- Replies

- 11

- Views

- 994

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)