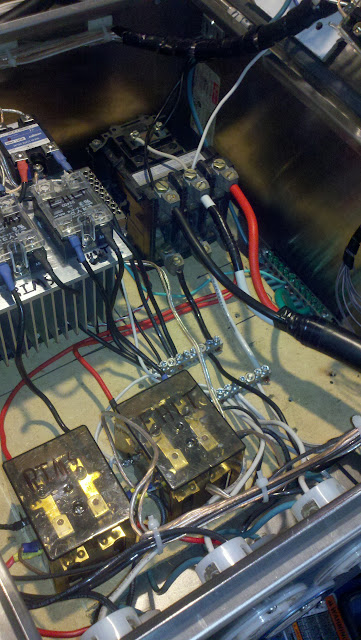

I know what they are, that's why I answered the question "what the hell are those?". Just helping him find what he's looking for. I was actually going to suggest the insulated strips, but he wasn't asking for those. I've done a lot of service work in the last 5 years, and I like to keep things as insulated as possible. The ground bars aren't really good to use for a power strip, because they're all metal, and unless you're fastening them to a nonconductive surface, they're useless. The op looks to have some kind of isolating barrier between the guts and those bars. I don't see any screws holding them in place, so they seem to be isolated from the metal box. Personally, when it comes to electricity, I wouldn't trust anything that isn't screwed or bolted in place.

True, the terminal blocks look nice, and are neat, but I"d rather splice everything together. If you know how to splice (seems simple, but I've seen some really bad splices over the years) then that splice will never come apart. A terminal block, in my mind at least, has multiple points of failure. Say you forget to really tighten down your hot wire screw, and over the years it loosens up and comes free. With a box that's jam packed, there's so much stuff that wire could come in contact with, cause an arc and set the whole thing on fire. Sure, it's probably far fetched, but electricity can kill you, quick. There's a lot of things that could go wrong. But like everything, we each have our own way of doing things, and mine is no more right than some others. If you put it together safely, then it should be fine.

Sorry, didn't mean that to sound like you didn't know what the grounding bar is. I intended it more as "that's x, I need y, would you know where to find that or what it is called?"

It also sounds like you think it would be better to solder it all together than use a terminal block type thing. Say I have 3 wires that all need to connected to the incoming hot line. Should I solder the three together onto a single line and then solder that line to the incoming hot line? The hot line coming into the box is a 6 or 8 gauge line (I don't recall, it's whatever is rated for 50amps). The wiring I'm using in the box for everything except the elements is 14 gauge.

Sorry to thread jack.

edit: great avatar BTW

Same boat for me.

Same boat for me.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)