This was a step mash with a protein rest... It had oatmeal in the grain bill.

I doughed in at 128 according to an oatmeal stout recipe, and then ramped up to mash temp.

Look guys,

The protein rest I used for this brew was an optional step, not required for 90% of the batches you'll make.... Only required when using unmodified malts.. But I'm not gonna spend time on what you already know. Maybe people read that, got confused, and stopped reading. A step mash is always more cumbersome, regardless of the system... But I probably should've omitted it to alleviate confusion. Could I have achieved the same results by removing that step and mashing in a few degrees higher than desired mash temp (as you would with any other system)? Yes ofcourse.

The point of my long write up was this: check your ph, and don't trust the digital controller completely as gospel.

Is this system as easy to use as Blichmann advertises? Yes absolutely,

If you're happy to boost your grain bill and accept efficiency in the mid 60's.

Is it capable of much more? Yup. Which is what I wanted to prove. It's much more of a pain to get there, and I may not go this far every time, but it's possible.

At the end of the day it's still much easier to use and clean than my previous 3-tier Gravity, cooler, and propane rig.

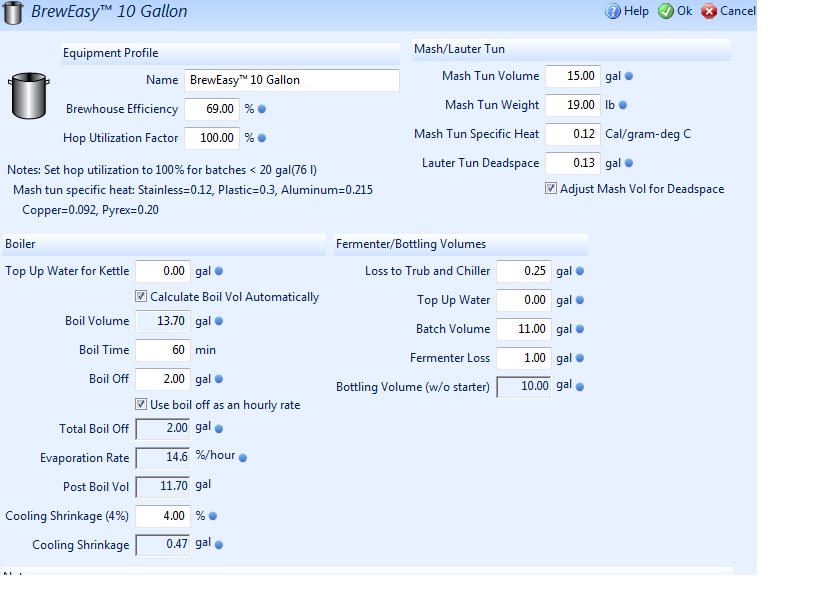

10 gallon Breweasy, 240v electric. System and kart purchased at great fermentations

I doughed in at 128 according to an oatmeal stout recipe, and then ramped up to mash temp.

Look guys,

The protein rest I used for this brew was an optional step, not required for 90% of the batches you'll make.... Only required when using unmodified malts.. But I'm not gonna spend time on what you already know. Maybe people read that, got confused, and stopped reading. A step mash is always more cumbersome, regardless of the system... But I probably should've omitted it to alleviate confusion. Could I have achieved the same results by removing that step and mashing in a few degrees higher than desired mash temp (as you would with any other system)? Yes ofcourse.

The point of my long write up was this: check your ph, and don't trust the digital controller completely as gospel.

Is this system as easy to use as Blichmann advertises? Yes absolutely,

If you're happy to boost your grain bill and accept efficiency in the mid 60's.

Is it capable of much more? Yup. Which is what I wanted to prove. It's much more of a pain to get there, and I may not go this far every time, but it's possible.

At the end of the day it's still much easier to use and clean than my previous 3-tier Gravity, cooler, and propane rig.

10 gallon Breweasy, 240v electric. System and kart purchased at great fermentations

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

but before I did 3 vessel brewing, I was a BIAB'er. The BIAB mash profile makes the most sense to me since you are using a full volume of water.

but before I did 3 vessel brewing, I was a BIAB'er. The BIAB mash profile makes the most sense to me since you are using a full volume of water.