pegasusherd

Active Member

Hi All,

I bought the BrewEasy (5-gal) in 2016 around the time it first came out. I used it a few times without ever truly dialing in my process, and after many years hiatus, I started again in 2023. Unfortunately, I still have yet to get my process fully dialed in, and would love some feedback from anyone who uses the system successfully.

(1) Mash-In. I calculate water temp with BeerSmith paying attention to also input correct gain temp. At first, when grain is sitting ~10 min in MT with ~50% of the water (the other 50% is below in BK), the temp is significantly low. Once I start recirculation, I have a lot of trouble getting MT up to correct mash temp. A few observations:

-- I think some heat is lost during the 10-15 min mash-in (prior to recirculation). This could probably be remedied by mashing in with water a few degrees hotter.

-- I’ve been making beers with a fair amount of wheat, oats, etc. and have had some issues with slow or stuck mashes. This contributes to the problem because the MT temp is initially low and when I cannot get the recirculation going quickly, the temp keeps falling.

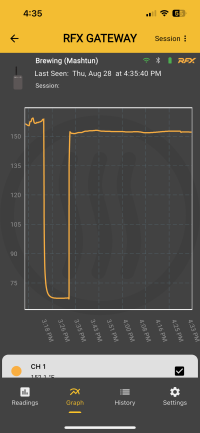

(2) Big Beers. For the first time I tried making a beer with a LOT of grain in the mash. 9 lbs two row, 3 lbs carapils, 5 lbs flaked oats, and 1.5 lbs rice hulls (pre-soaked). Many of the problems above were exacerbated and then some. MT temp was low to begin with. Had some trouble getting the recirculation going cleanly and by this time, MT was even lower and so the Boil Kettle had to ramp up temps very high (180 at one point) to get the MT back to temp. I assume this denatured a good portion of the enzymes because after a very long mash, I had absolutely terrible efficiency and ended up needing to compensate with DME.

Overall, I think the solution is to get the recirculation started rapidly after the 10-15 min mash-in period. Rather than trying to perfect this with simple recipes, I’ve been using lots of wheat, oats, etc. which is not helping the process.

Overall, to any BrewEasy users out there, any tips for (1) mash-in and (2) big beers that you can share? Thanks for reading, and for any suggestions you may have.

Chris

I bought the BrewEasy (5-gal) in 2016 around the time it first came out. I used it a few times without ever truly dialing in my process, and after many years hiatus, I started again in 2023. Unfortunately, I still have yet to get my process fully dialed in, and would love some feedback from anyone who uses the system successfully.

(1) Mash-In. I calculate water temp with BeerSmith paying attention to also input correct gain temp. At first, when grain is sitting ~10 min in MT with ~50% of the water (the other 50% is below in BK), the temp is significantly low. Once I start recirculation, I have a lot of trouble getting MT up to correct mash temp. A few observations:

-- I think some heat is lost during the 10-15 min mash-in (prior to recirculation). This could probably be remedied by mashing in with water a few degrees hotter.

-- I’ve been making beers with a fair amount of wheat, oats, etc. and have had some issues with slow or stuck mashes. This contributes to the problem because the MT temp is initially low and when I cannot get the recirculation going quickly, the temp keeps falling.

(2) Big Beers. For the first time I tried making a beer with a LOT of grain in the mash. 9 lbs two row, 3 lbs carapils, 5 lbs flaked oats, and 1.5 lbs rice hulls (pre-soaked). Many of the problems above were exacerbated and then some. MT temp was low to begin with. Had some trouble getting the recirculation going cleanly and by this time, MT was even lower and so the Boil Kettle had to ramp up temps very high (180 at one point) to get the MT back to temp. I assume this denatured a good portion of the enzymes because after a very long mash, I had absolutely terrible efficiency and ended up needing to compensate with DME.

Overall, I think the solution is to get the recirculation started rapidly after the 10-15 min mash-in period. Rather than trying to perfect this with simple recipes, I’ve been using lots of wheat, oats, etc. which is not helping the process.

Overall, to any BrewEasy users out there, any tips for (1) mash-in and (2) big beers that you can share? Thanks for reading, and for any suggestions you may have.

Chris

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)