Steven Deeds

Member

- Joined

- Oct 22, 2014

- Messages

- 5

- Reaction score

- 0

Each of the parts in this series will stand alone, but you might be interested in reading the kickoff article: 4 Tips for Making Great Beer in 15 Minutes.

One of the most wonderful things about brewing is that every step can be accomplished by a multitude of methods. The advantages of a particular method may make one preferred over others by some brewers, but this doesn't necessarily make one method universally better than the others. These 15 minute brew articles are a summary of what works for me with a focus on some techniques that you may not have heard of. My goal is that every brewer will find some useful information in these articles and, for those interested, the procedure will be laid out start to finish.

The most common method for adding hop bitterness to beer by far is the traditional ventilated wort boil, and for good reason: The wort needs to be boiled for sterilization purposes making it a convenient time to also add bittering hops. However, if the wort does not need to be boiled, as is the case for brewing with dry extracts, other options may be better suited for adding bitterness.

Hop tea can be a convenient method for adding bitterness to beer. Because a smaller volume of water is required, it takes less time get to, and return from boil. Because there is no sugar or extract in solution there is a lower chance of a boil over. And if it does happen, you aren't going to be scrubbing a sticky mess off of your stove. Hop tea can be made ahead of time for multiple batches, and it's easy to make. Hops can be boiled in water on the stove, in the microwave, or in a hot pot. Other common methods are using a percolator, or using a French Press. My book Brewing Engineering has some more details on hop tea. One of the more obscure methods is the one I will focus on in this article: the use of a pressure cooker. The same bittering levels of a traditional 60 minute boil can be achieved with a pressure cooker in 10.

Bittering six times faster may sound like a farce, but I assure you, there is no deception here, only a carefully engineered solution. Replacing your boil kettle with a pressure cooker uses the same amount of hops with the same alpha-acids to achieve the same bitterness levels. The big difference is time. Including the time for heating and cooling, a 60 minute boil may take 2 hours to complete, while a 10 minute boil in a pressure cooker can take less than 15 minutes.

For a given set of conditions, alpha-acids in hops are isomerized at a constant rate and can be described as a first order kinematic reaction. The rate at which this occurs is expressed as conversion per time and is known as the rate constant. Jaskula [1] demonstrated that the rate constant exhibits Arrhenius behavior in that the rate is a function of temperature and activation energy. Malowiki [2] demonstrated this behavior over a temperature range of 195F to 265F (90C to 130C).

Isomerization of alpha-acids in hops can therefore be expressed as a function of not only time, but temperature as well.

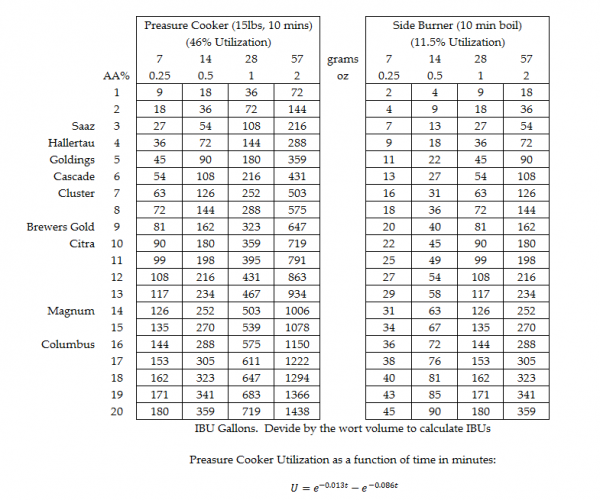

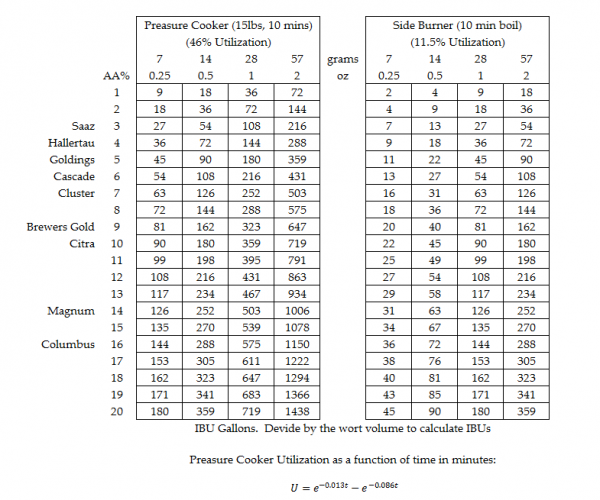

The equation, table, and chart summarize the relationship between temperature and conversion rate. The conversion rate is the percentage of available alpha-acids that are isomerized per minute.

The high temperature of the pressure cooker presents a new challenge that doesn't exist with the traditional boil. Along with increasing the rate of isomerization at high temperatures, the rate of degradation also increases. Using the characterization that Malowiki[2] identified, the peak in utilization can be identified for the pressure cooker and traditional boil. Using a traditional boil the maximum utilization occurs around 150 minutes. In a pressure cooker the elevated temperature causes peak utilization to occur six times faster at only 25 minutes. The hop tea will actually become less bitter if cooked for more than 25 minutes in a pressure cooker.

Dissolved alpha-acids vs pH - Spetsig[5]

When using any form of a partial boil to add hop bitterness, alpha-acid solubility must be considered. Although the same amount of isomerization occurs in a partial boil, only small amount is actually dissolved. You may have heard that 100 IBUs is the maximum achievable bitterness in beer. This likely stems from the solubility of alpha-acid, which is 90 parts per million at 5.2 pH and 20 degrees Celsius. (1 IBU is equal to 1ppm of isomerized alpha-acids[3]) In practice, the solubility will be higher at this phase in the brewing process. Spetsig[5] Characterized alpha-acid solubility and noted that solubility increases with pH. At a pH of 7 (that of neutral water), the solubility is 3000 times higher than at a pH of 5.2. This works to our advantage because the pH will typically be higher when boiling without extract. During a traditional boil, wort acts as a buffer, reducing the pH. When only boiling the hops, there is very little to buffer the solution, and alpha-acids are very weak. The result is that the pH is much closer to 7. When 1oz of 6%AA hops are dissolved in 1 cup of distilled water the pH measures about 6.5. At this pH level, the solubility is 1000ppm (or 1000 IBUs).

Using the 15 minute brew method only a small amount of water (typically 20% of the total) is boiled to speed the brewing processes. If a saturated 100 IBU solution is simply diluted five to one, the maximum resulting bitterness is a disappointing 20 IBUs. To solve this problem, we can borrow a technique from all-grain brewing: laughtering. After the hops are boiled, the vessel can be topped off with water before pouring through a strainer into the fermenter. The additional water can then be poured through the hops in the strainer. This is effectively a fly-sparge. Because the total volume of water that came into contact with the hops is the full volume of the beer the bitterness level will be the same as if a full volume boil was conducted.

For most pressure cookers, at 15 lbs of pressure, the time is simply the bittering hop boil time divided by 6. To use the table above, multiply the bittering IBU target of your beer by the volume. Find the closest value in each column on the table. To the left is the alpha-acid content, and above is the weight of hops required.

Using the pressure cooker to replace my boil kettle has worked for me, and I hope it works for you.

[1] Jaskula, B. J., A Kinetic Study on the Isomerization of Hop Alpha-Acids. 2008.

[2] Malowicki, M. G., Hop Bitter Acid Isomerization and Degradation Kinetics in a Model Wort-Boiling System. 2005.

[3] http://en.wikipedia.org/wiki/Beer_me...ent#Bitterness

[4] http://en.wikipedia.org/wiki/Isohumulone

[5] Spetsif, L. O., Electrolytic Constants and Solubilities of Humolinic Acid, Humulone, and Lupulone, Ata Chem. Scand. 9:1421-1424, 1955

***

Steven Deeds is "The Woodland Brewer". For more from this Brewer/Author visit him at his site, woodlandbrew.com, or find his book "Brewing Engineering" on Amazon.

From Steven, and everyone at HomeBrewTalk we want to wish you a Happy New Year!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)