Like they've been spying on me? Mmmhmmm...I would think a smoker, gas grill, etc. wouldn't be considered open flame. Fire pit and propane burner, yes. Seems odd that they mentioned open flames and propane tanks. Makes you kind of wonder . . .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BIAB vs 3 vessel setups

- Thread starter Travis H

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Travis H

Active Member

Scary

Travis H

Active Member

Gotta keep an eye out for THE MAN!!!!Like they've been spying on me? Mmmhmmm...

I brew ten gallon batches with a 25 gallon kettle. I'd recommend a larger kettle.I have done mostly BIAB brewing. Mostly 3-5 gallon batches. Currently I have a basic 8 gallon kettle. I am looking at getting a 20 gallon kettle with the ports so I can hook up a pump. I am looking to be able to do 10-12 gallon batches but still do some in the 5-7 gallon batches.

These threads are popping up more and more on the forum. If you still want some functionality of a 3 vessel but like the bells and whistles of BIAB, my advice is to get two AIOs. Use one for the mash and one for the boil. Then one can be an HLT too. And later you can utilize the open one for holding chilling water as well. You can lauter away from the grain bag so you do not need to lift the full bag of wet grain. This also allows for some advanced techniques like underletting the strike water into your mash.

Two Anvil Foundrys or two Digiboils would not be that expensive in comparison to what is on the market.

Two Anvil Foundrys or two Digiboils would not be that expensive in comparison to what is on the market.

I never tried 3 vessel because I always read something like 3x vessels equals 3x cleaning {shudder}. As I know how important cleanliness is for good beer, I’d rather produce good beer with less cleaning and a smaller footprint.

I have a spike custom solo BIAB setup I bought from a great dude on this forum. He had it customized to use 2x 110v heating elements, and if 220 is a problem this could be a route for you. Bobby at Brewhardware.com even has Blichmann controllers wired for dual 110. I currently just run 1 through a controller and a second hard plugged or removed for ramp/boil v. temp maintaining. You just have to make sure your elements are plugged into separate circuits which is easily done with a standard extension cord.

I’ve often considered moving to 220 for the extra speed to temp, but with 2x110 I still get something like 3200w of heat so it’s just me wanting to get as efficient as I can with brew time.

I have a spike custom solo BIAB setup I bought from a great dude on this forum. He had it customized to use 2x 110v heating elements, and if 220 is a problem this could be a route for you. Bobby at Brewhardware.com even has Blichmann controllers wired for dual 110. I currently just run 1 through a controller and a second hard plugged or removed for ramp/boil v. temp maintaining. You just have to make sure your elements are plugged into separate circuits which is easily done with a standard extension cord.

I’ve often considered moving to 220 for the extra speed to temp, but with 2x110 I still get something like 3200w of heat so it’s just me wanting to get as efficient as I can with brew time.

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

Be careful with 2 x 120v elements. 3200w of heat is over the ~2000w normal load of a single outlet panel breaker. Make sure each element is plugged into its own breaker. Just a PSA

Yes, very important here! I brew near the kitchen so one line goes onto that circuit and the other from a separate breaker circuitBe careful with 2 x 120v elements. 3200w of heat is over the ~2000w normal load of a single outlet panel breaker. Make sure each element is plugged into its own breaker. Just a PSA

I've recently told myself to back off on these conversations because they do seem to get a little heated and everyone really wants to defend the choices they've made. I'll be restrained for now.. I couldn't agree more with these two points.Two things I’ve changed, in order, and couldn’t be paid to reverse.

1. Propane to electric

2. 3v to 1v BIAB.

I’m not saying it’s for everyone and I get there might be logistical issues but its been a godsend for me.

I have done mostly BIAB brewing. Mostly 3-5 gallon batches. Currently I have a basic 8 gallon kettle. I am looking at getting a 20 gallon kettle with the ports so I can hook up a pump. I am looking to be able to do 10-12 gallon batches but still do some in the 5-7 gallon batches.

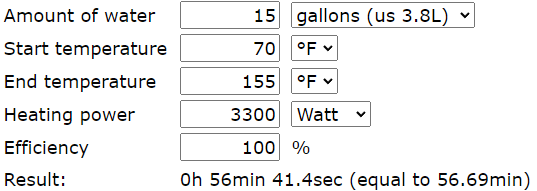

If 12 gallon batches are desired, even occasionally, it's not going to happen on a 120v electric system. Well.... As someone brought up elsewhere in this thread, a system can be built to use two 120v x 1650 watt elements plugged into two distinct circuits, but that's a great solution for 5/6 gallon batches but less so for larger batches. Here's the real world....

5/6 gallon BIAB batch initial strike water heat up:

10/11 gallon version:

I suppose an hour is not the end of the world, but also factor in the ramp up to boil time and the fact that 3300 watts is just barely enough to get 13/14 gallons to a simmer.

If you can work out brewing pretty close to where your main circuit breaker panel is, and don't mind the cost to add a 240v outlet, this is more like it:

Edit: I forgot that there was one customer that just absolutely wanted to stick to 120v because he was always moving (military) and wanted to be able to brew anywhere without always adding 240v circuits. I put THREE 1650w elements in the kettle. It took some interesting element bends at the time, but now I could probably work it out via TC port arrangement.

Most of the choices I've made are based on being a real cheapskate who is married to an even bigger cheapskate. That's the extent of my defense.I've recently told myself to back off on these conversations because they do seem to get a little heated and everyone really wants to defend the choices they've made.

One of these days I'll probably get around to moving the now-unused dryer outlet over to the garage door, maybe even outside. Then maybe I'll ask Santa for recirculating eBIAB system.If you can work out brewing pretty close to where your main circuit breaker panel is, and don't mind the cost to add a 240v outlet

There are pros and cons that can be listed for each system type but they are always going to be contextual for the goals of any given brewer.Looking to get back into doing some brewing again. Just wondering 3 vessel or BIAB system. Is there any real benefit to the 3vessel systems?

For example, that list would look very different if you knew that you wanted to work up to being a head brewer on a 10BBL brew house in the next few years.

Personally, and for most of the excellent brewers I have gotten to know over the years, high power electric single vessels are the way to go. Some of them have had years of experience on various 3 vessel rigs of varying sophistication (gravity driven, mostly passive vessels (coolers and such) all the way up to full electric controlled HERMS and then later converted to eBIAB. Others jumped into eBIAB as their first all grain brewing rig based on recommendations of others. How they arrive there is less important, but the recurring theme is most people stick with that and they make great beers.

There's an allure to a big brew house with a bunch of plumbing and pumps. I still stand back and admire them every time I deliver a custom system to a customer who walks in with a blank check and unwavering demands. I should also follow this up with the fact that a good portion of those customers telegraph (or outright admit) regret after several brew days. I've been hired to teach those customers how to run that system many times. You have to want the additional hands on for it to pay off.

To be fair, My HLT is only used for heating water. I use it to collect hot water at the end from the chiller, but that is still clean water that I then use for cleaning. And while the mash tun has to be cleaned, it's a quick rinse to get all the sugars out. I did just switch to a new bottom draining mash tun that I will be using with a bag, so we will see of it makes it any easier.I never tried 3 vessel because I always read something like 3x vessels equals 3x cleaning {shudder}. As I know how important cleanliness is for good beer, I’d rather produce good beer with less cleaning and a smaller footprint.

I don't see this as that much more than cleaning the boil kettle and all of the hoses, pumps, chiller etc.. which you have to do with an AIO system as well. Still have to clean the fermentor(s), kegs/bottles on both as well. I think doing what works for you is what you should do.

For me though, and I am fortunate to have a dedicated brew area in my house with a large sink for cleaning, the ability to set up the night before, with all the grains ready to go, water collected etc.. and wake up to strike temp water, transfer into the mash tun, then go get coffee, shower, makes it well worth it.

That’s fair, but also sounds a bit like you had to buy more (expensive) things to make it as easy to clean as a BIAB setup might be.To be fair, My HLT is only used for heating water. I use it to collect hot water at the end from the chiller, but that is still clean water that I then use for cleaning. And while the mash tun has to be cleaned, it's a quick rinse to get all the sugars out. I did just switch to a new bottom draining mash tun that I will be using with a bag, so we will see of it makes it any easier.

But this is a pretty significant difference for me as well. With my current house layout I’m essentially renting our common space for brew day. I might feel differently if I had a dedicated room (though I honestly suspect not).For me though, and I am fortunate to have a dedicated brew area in my house with a large sink for cleaning, the ability to set up the night before, with all the grains ready to go, water collected etc.. and wake up to strike temp water, transfer into the mash tun, then go get coffee, shower, makes it well worth it.

Having a dedicated brewing space makes every system easier to operate. I would suspect a single vessel with one pump is at least twice as easy to haul out and setup (and also break down and store away) than a 3 vessel with two pumps or whatever the configuration actually is.

If I had to do any of that stuff, I'd probably go with an all in one. You can literally carry out one piece of gear.

If I had to do any of that stuff, I'd probably go with an all in one. You can literally carry out one piece of gear.

I agree.. The dedicated space alone saves me a significant amount of time carting equipment from basement to garage and back. Space and finances have not always allowed me to have this, but man, it's nice.Having a dedicated brewing space makes every system easier to operate. I would suspect a single vessel with one pump is at least twice as easy to haul out and setup (and also break down and store away) than a 3 vessel with two pumps or whatever the configuration actually is.

If I had to do any of that stuff, I'd probably go with an all in one. You can literally carry out one piece of gear.

There's also a habit part.. There were not AIO systems when I started brewing, and I've spent years slowly upgrading my keggle based system. So I'm comfortable with it, I know what to expect, and I enjoy the process. It's good for me to have time to relax, listen to some music, and do my thing. If it were simplified to push a button, I don't think I would get the down-time as I would attempt to do other stuff while I brew.

I agree.. The dedicated space alone saves me a significant amount of time carting equipment from basement to garage and back. Space and finances have not always allowed me to have this, but man, it's nice.

There's also a habit part.. There were not AIO systems when I started brewing, and I've spent years slowly upgrading my keggle based system. So I'm comfortable with it, I know what to expect, and I enjoy the process. It's good for me to have time to relax, listen to some music, and do my thing. If it were simplified to push a button, I don't think I would get the down-time as I would attempt to do other stuff while I brew.

I think the single vessel systems are incorrectly viewed by many as a beer Keurig or something. It's very much still hands on for all but maybe the temperature stability of the mash. That's one hour where you COULD walk away if you wanted to. You could also just sit there and stare into space if you want.

G_robertus

Well-Known Member

I have a small stovetop 3V system and large AIO. I liked the process of the 3V system much more (especially since I got the third pot that made sparging so much easier). I still use my smaller system for test batches and other stuff I don't need too much of, when I want to top up a sour for example or when I want to brew something I can't on the AIO. I have noticed that recently I've switched over to BIAB + batch sparge on the small system because it's so much faster. BIAB + batch sparge gets me pretty much the same efficiency as 3V + batch sparge (75-80%, usually 77%). I'm not a fan of no sparge on this system as I drop way too many points and don't feel like I gain much, but rather lose flavour (and money on grain).

So I would say you do not necessarily miss out on a lot if you sparge, though others might not agree.

I also prefer the process of my small system over that of the larger system. I seem to enjoy the beer more, but I'm not sure if that is because of the relative effort, the boil or something else. I do like the benefit of time saved with recirculation, which my 3V doesn't have. However, there are also many other things I could point out I don't like about electric AIO.

So I would say you do not necessarily miss out on a lot if you sparge, though others might not agree.

I also prefer the process of my small system over that of the larger system. I seem to enjoy the beer more, but I'm not sure if that is because of the relative effort, the boil or something else. I do like the benefit of time saved with recirculation, which my 3V doesn't have. However, there are also many other things I could point out I don't like about electric AIO.

LegacyBanker

Member

Can you post an image of this and where did you buy the pulley?If you have a 6/8ft ladder you hook your pulley to that over your boil kettle.

This isn't mine, I use a 3v system, this is my brother's. Harbor Freight has rope pulleys.Can you post an image of this and where did you buy the pulley?

Attachments

Last edited:

This. I enjoy the alone time. I can sit in the garage, put on my music and watch water either boil, or soak up into grains. To me, and being a very simple minded guy, this is a day well spent. Almost as good as playing golf, of course because I can drink beer when I do that. LOL>I agree.. The dedicated space alone saves me a significant amount of time carting equipment from basement to garage and back. Space and finances have not always allowed me to have this, but man, it's nice.

There's also a habit part.. There were not AIO systems when I started brewing, and I've spent years slowly upgrading my keggle based system. So I'm comfortable with it, I know what to expect, and I enjoy the process. It's good for me to have time to relax, listen to some music, and do my thing. If it were simplified to push a button, I don't think I would get the down-time as I would attempt to do other stuff while I brew.

If I remember correctly, Alton Brown (yes the cook) had a setup on his website that he used to lift turkey's he had fried in buckets of oil. Here is the link:Can you post an image of this and where did you buy the pulley?

https://altonbrown.com/how-to-build-a-turkey-derrick/

- Joined

- May 28, 2018

- Messages

- 3,262

- Reaction score

- 2,971

To the original question; I like my 3V rig and don't see going BIAb at this point. Next brew I make will be 200th 10 Gal batch in this rig. First 35 or so were propane fired, then I went electric.

As brewing got more routine, I've run series of batches with some constants and limited variables, such as three pilsner batches in a row trying different malts with same hops and yeast. Ditto with same malt & different hops, same malt with different yeasts.

Anyway, I've gotten pretty good at brewing what I want to drink while continuously refining process and trying different inputs.

For me, a 3V rig is the way to go, doing what I'm doing, as I can separate process into definable parameters. The seemingly more complicated rig being simpler as inputs results are more easily defined and measured.

As brewing got more routine, I've run series of batches with some constants and limited variables, such as three pilsner batches in a row trying different malts with same hops and yeast. Ditto with same malt & different hops, same malt with different yeasts.

Anyway, I've gotten pretty good at brewing what I want to drink while continuously refining process and trying different inputs.

For me, a 3V rig is the way to go, doing what I'm doing, as I can separate process into definable parameters. The seemingly more complicated rig being simpler as inputs results are more easily defined and measured.

Here's my rig. I use an 8 ft step ladder (more room to work under it than with a 6 footer.) I don't use the perforated basket anymore, just the bag. I got the pulley from Wilser with the bag. And I have a better burner now.Can you post an image of this and where did you buy the pulley?

Brew on

- Joined

- Jan 3, 2020

- Messages

- 3,226

- Reaction score

- 3,908

You may know this but depending on the age of the residence, there may two 20 amp GFCI countertop branch lines as that is code for a kitchen. Not sure if that extends to multi-unit dwellings but it would be obvious if there were two GFCI outlets along the countertops.Yes, very important here! I brew near the kitchen so one line goes onto that circuit and the other from a separate breaker circuit

- Joined

- Jan 3, 2020

- Messages

- 3,226

- Reaction score

- 3,908

Wheels on the brew table makes both equal if you can wheel out the brew rig from its storage space. Does not apply to everyone.Having a dedicated brewing space makes every system easier to operate. I would suspect a single vessel with one pump is at least twice as easy to haul out and setup (and also break down and store away) than a 3 vessel with two pumps or whatever the configuration actually is.

If I had to do any of that stuff, I'd probably go with an all in one. You can literally carry out one piece of gear.

- Joined

- Jan 3, 2020

- Messages

- 3,226

- Reaction score

- 3,908

I have a laundry sink in the garage that I installed that gets used heavily for brewery cleanup. But that could be used for either. Other than that, I just have a couple different brushes, a garden hose sprayer, scrubbies, and rags which are used to clean the vessels. A bag can be used in the MT to begin with if one wanted to but I get the feeling cleaning the bag is about the same as cleaning the false bottom of the MT. I've cleaned mesh bags before that held grains and hops. Stuff collects on the seams which takes time. Personally, I'd rather clean the false bottom. I do have a different mash tun in the works myself as well, which will be easier to clean as it's the SS brewtech insulated one vs. a keggle, but it's also for better efficiency and a slight weight savings. I will be getting rid of the lip around the keggle opening at the top which is awkward to scrub and makes dumping the grains harder.That’s fair, but also sounds a bit like you had to buy more (expensive) things to make it as easy to clean as a BIAB setup might be.

...

Yeah, definitely depends on the age of the dwelling. My kitchen had one 15 amp and one 20 amp circuit when I bought the house, and no GFCI. Built in 1967, new 200 amp service installed by second owner in 1994. NEC didn't require GFCI for all kitchen counter receptacles until 1996, and who knows when any particular jurisdiction implemented that requirement.depending on the age of the residence, there may two 20 amp GFCI countertop branch lines as that is code for a kitchen

- Joined

- Jan 3, 2020

- Messages

- 3,226

- Reaction score

- 3,908

The aughts I think would be a good guess for many jurisdictions. And I'll say while two GFCI receptacles is a good indication, the owner/renter/handyperson may have installed another one on the same line not knowing just the first one upstream is needed or thinking the second outlet was a second line, or even trying to put one over on the inspector. Hit the test button and check which outlets work and don't to be safe!Yeah, definitely depends on the age of the dwelling. My kitchen had one 15 amp and one 20 amp circuit when I bought the house, and no GFCI. Built in 1967, new 200 amp service installed by second owner in 1994. NEC didn't require GFCI for all kitchen counter receptacles until 1996, and who knows when any particular jurisdiction implemented that requirement.

Similar threads

- Replies

- 7

- Views

- 574

- Replies

- 14

- Views

- 675

- Replies

- 11

- Views

- 817

- Replies

- 0

- Views

- 368

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)