The_Bishop

Well-Known Member

- Joined

- Dec 8, 2013

- Messages

- 2,100

- Reaction score

- 676

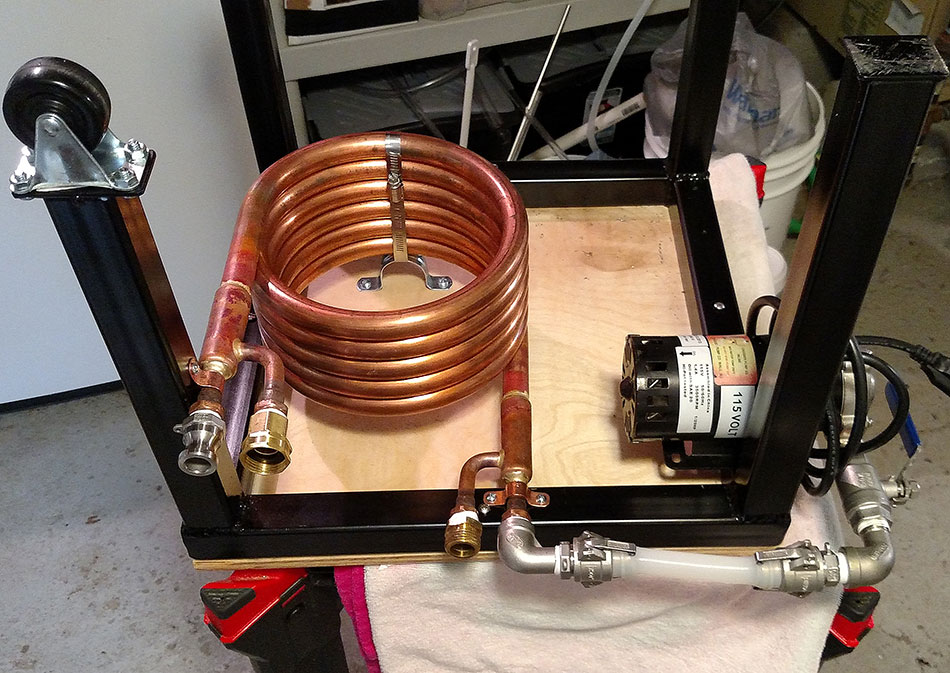

I've decided to finally build a brew stand. After much deliberation, and accounting for the lack of space for storage, I decided to make a return to BIAB, since I can build a BIAB stand that's pretty compact.

This is today's progress. I still need to design the overhead boom to support the bag for draining.

This is today's progress. I still need to design the overhead boom to support the bag for draining.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

![41eyIOBtSDL._SX425_[1].jpg 41eyIOBtSDL._SX425_[1].jpg](https://cdn.homebrewtalk.com/data/attach/253/253972-41eyIOBtSDL.-SX425-1-.jpg)