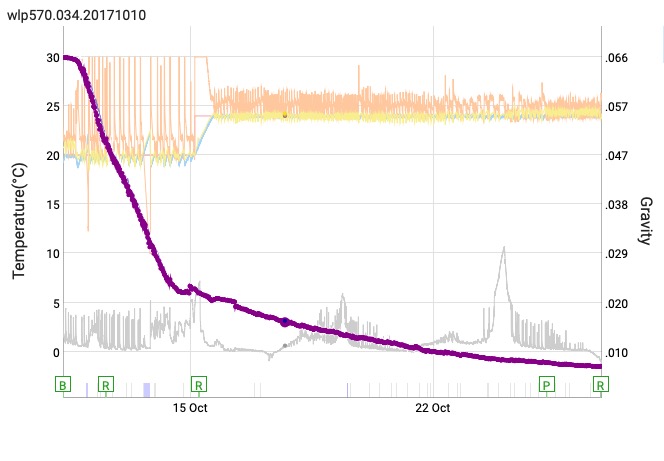

The goal: indirectly figure out the amount of alcohol produced based on the amount of CO2 emitted.

From what I've read, it's nearly a 1:1 ratio, by weight, of emitted CO2 and generated alcohol. So, if 100 grams of CO2 are emitted, roughly 100 grams of alcohol would have been produced. If you know your must volume, then you could derive the alcohol percentage without having to open up your fermentation vessel and use a thief with a hygrometer.

So, that's the idea and the goal. It's probably easier to measure the total volume of CO2 emitted and then derive from that the weight of the CO2. So, what's the best sensor for that? Not sure how accurate it would be, but a digital bubble counter could be used to estimate it:

With a humidity and temperature sensor, you could probably also deduct the water vapor from the total gas emitted.

Is there a better way to automate the measurement? Or am I looking at this wrong, and maybe there's already some completely different way to automatically gauge the alcohol content in your wine or other brew?

Another way to measure the CO2 weight would be to put a scale under the fermenter and measure how much the weight goes down. I think that might be easiest, but for an automated system, you wouldn't be able to re-zero between the measurements, and so I don't know how accurate the measurements would be over time, short of automating a robotic way to lift the fermentation vessle up, re-zero the scale, and then place it down again.

Anyone tried either of these ways?

From what I've read, it's nearly a 1:1 ratio, by weight, of emitted CO2 and generated alcohol. So, if 100 grams of CO2 are emitted, roughly 100 grams of alcohol would have been produced. If you know your must volume, then you could derive the alcohol percentage without having to open up your fermentation vessel and use a thief with a hygrometer.

So, that's the idea and the goal. It's probably easier to measure the total volume of CO2 emitted and then derive from that the weight of the CO2. So, what's the best sensor for that? Not sure how accurate it would be, but a digital bubble counter could be used to estimate it:

With a humidity and temperature sensor, you could probably also deduct the water vapor from the total gas emitted.

Is there a better way to automate the measurement? Or am I looking at this wrong, and maybe there's already some completely different way to automatically gauge the alcohol content in your wine or other brew?

Another way to measure the CO2 weight would be to put a scale under the fermenter and measure how much the weight goes down. I think that might be easiest, but for an automated system, you wouldn't be able to re-zero between the measurements, and so I don't know how accurate the measurements would be over time, short of automating a robotic way to lift the fermentation vessle up, re-zero the scale, and then place it down again.

Anyone tried either of these ways?

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)