About a year ago, I decided I was done hauling 5+ gallons of wort out of my garage, through my kitchen, down the stairs and across my basement to where my fermentation chamber was located. I probably spent a 1/2 year (on and off) cleaning and throwing away "stuff" in my basement in order to make room for a brewery area. There was only one spot it was going to work and that was about a 11' by 7" area in the back corner of the unfinished basement. This was my journey...

Replaced the old tired utility sink with with a stainless 4.5' x 2' (bin 18"x18") cleaning area...

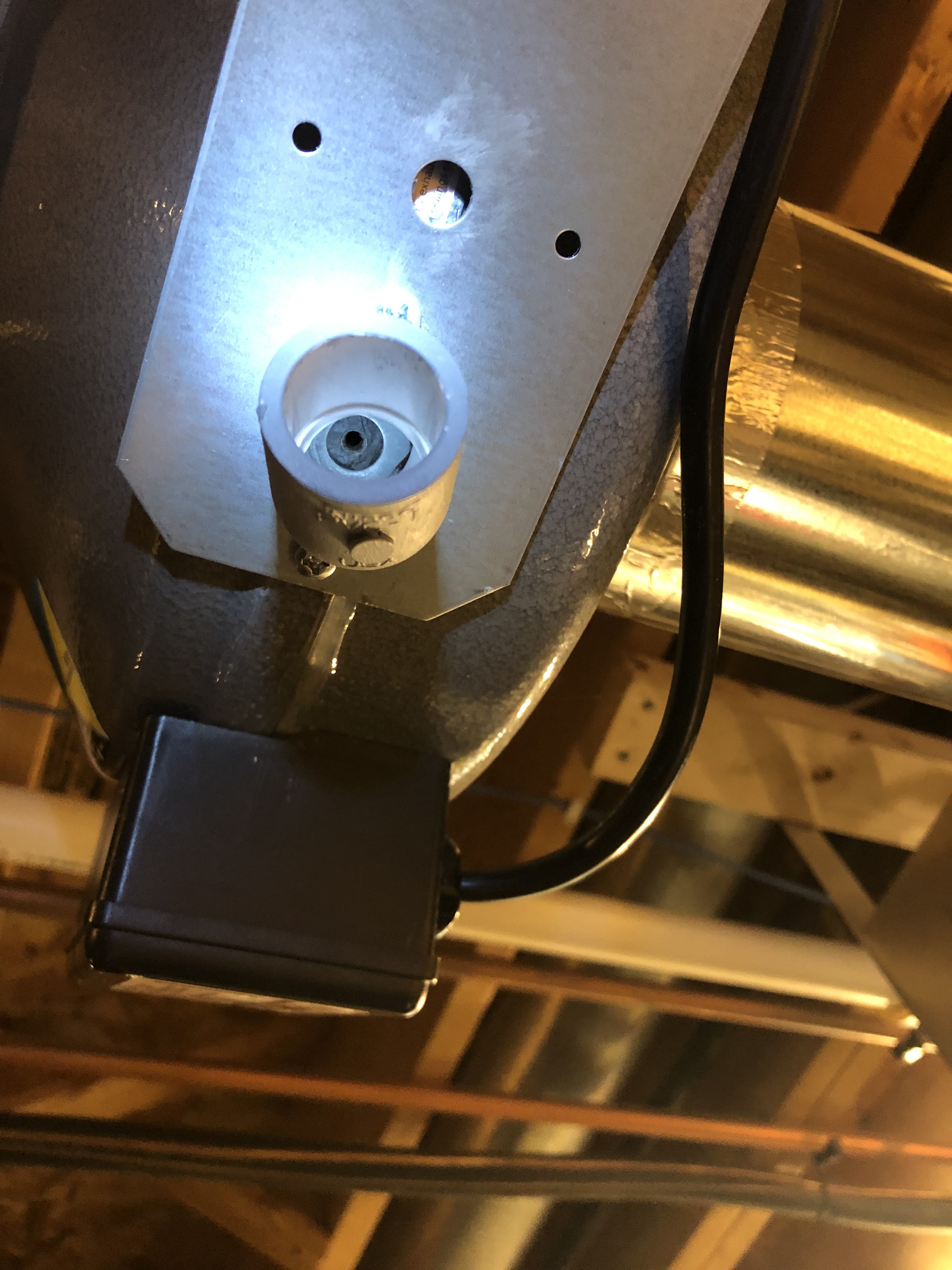

Installed a RO System...

Setup a 72"x30" stainless table in the recently cleaned up brewery space...

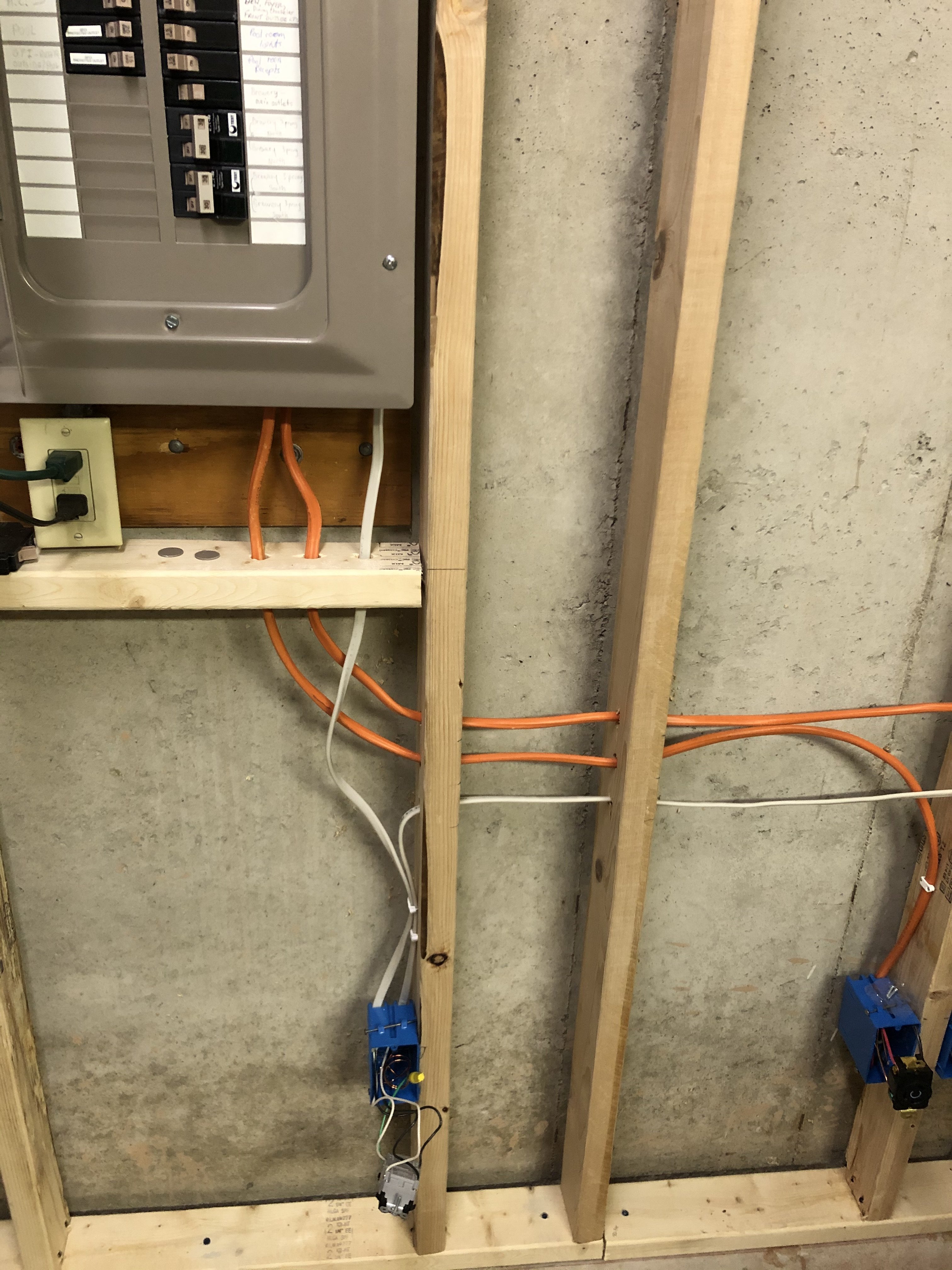

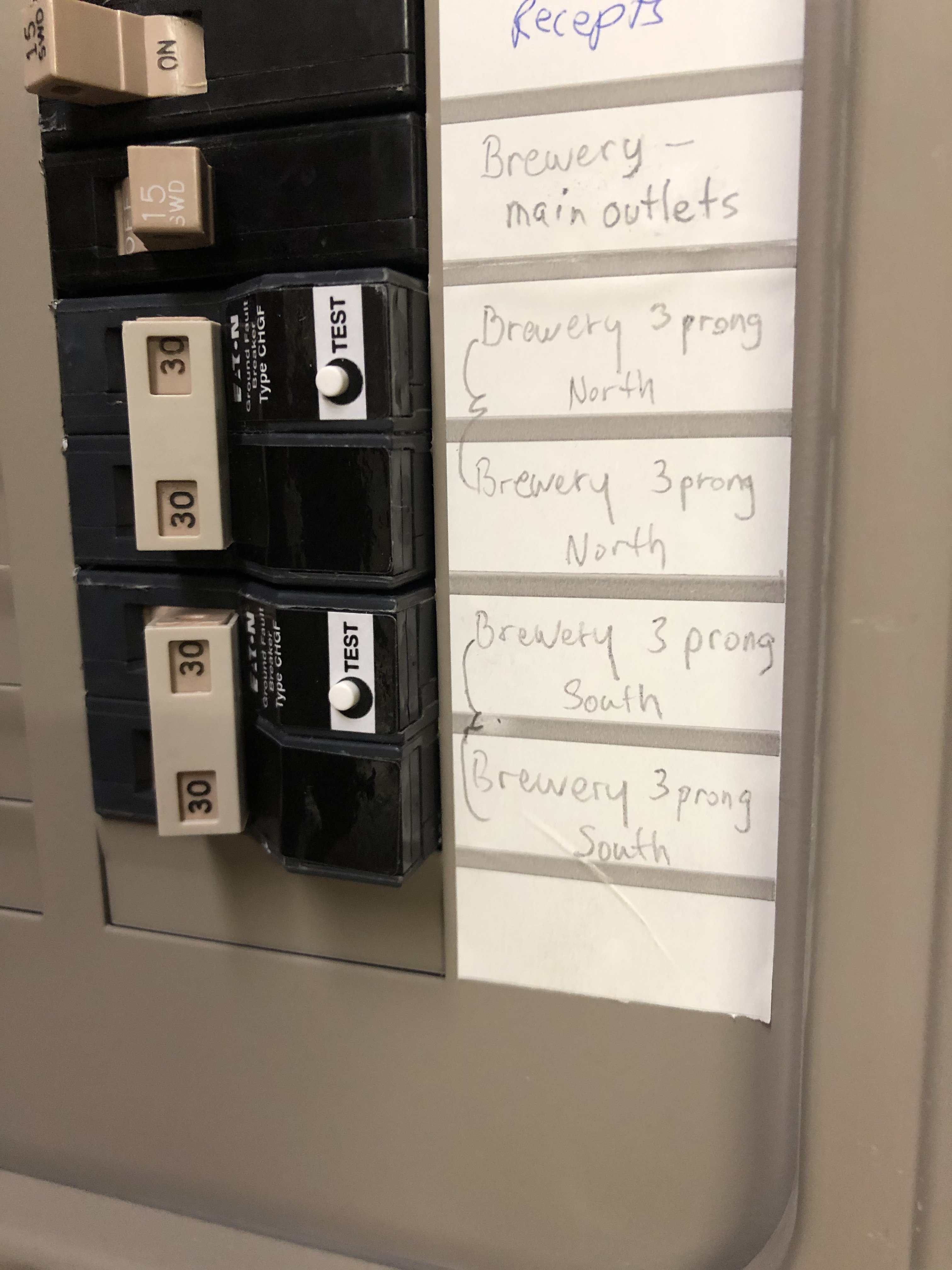

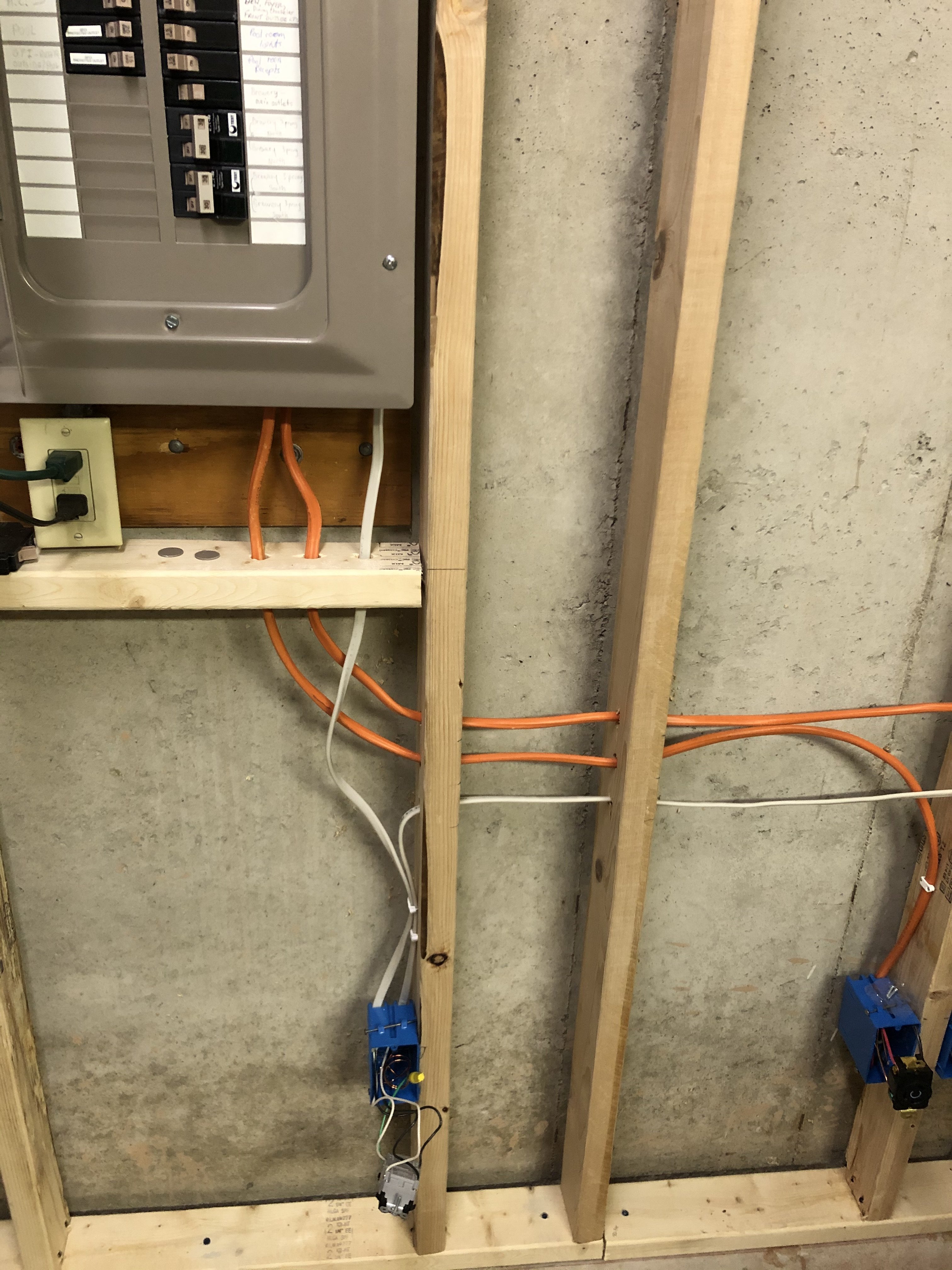

Framing complete for electrical, RO water hose and an eventual pine board finish...

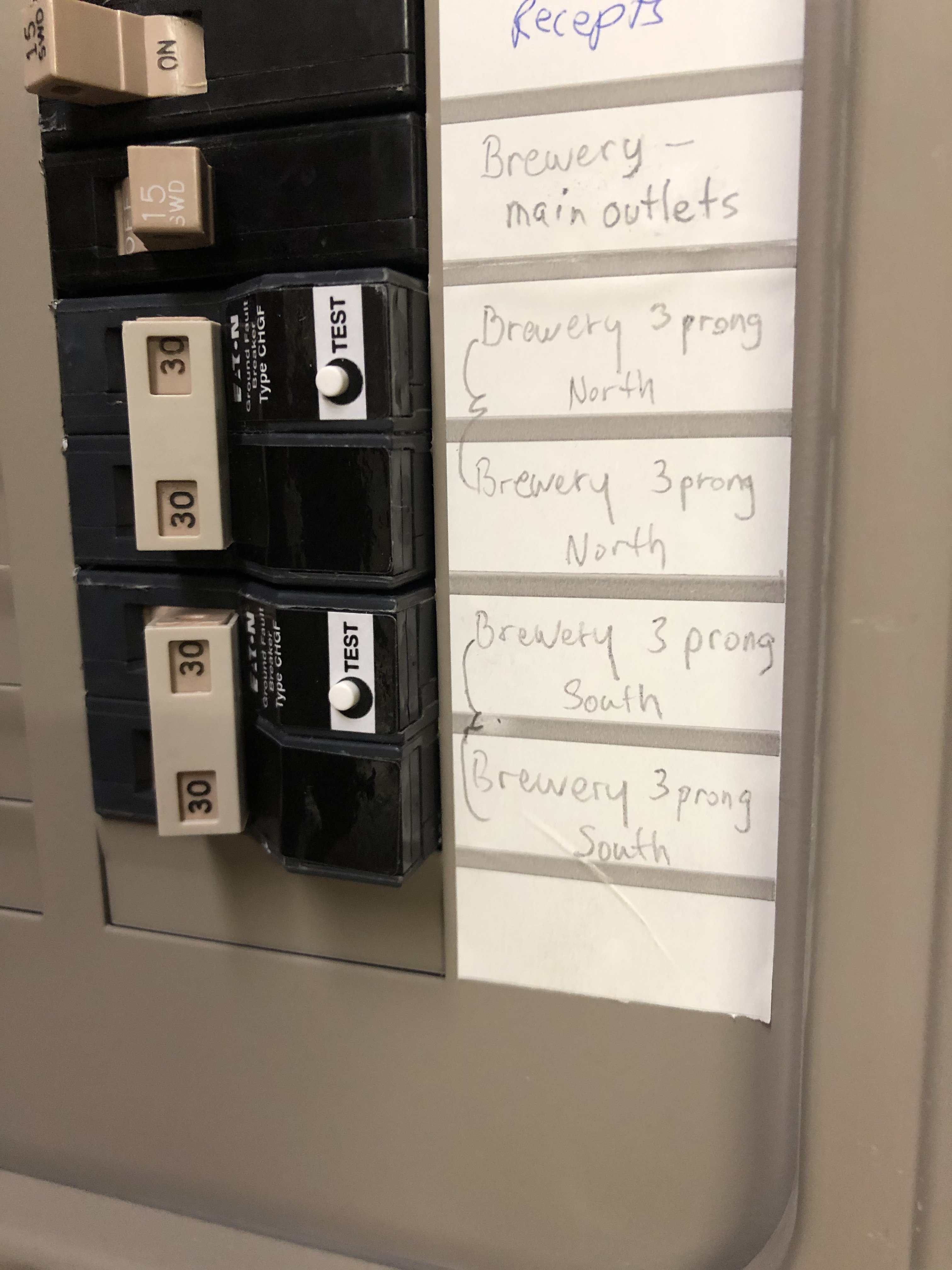

Required electrical purchased: (2) 30amp outlets, (1) GFCI 15amp outlet, (4) standard 15amp outlets, 10 & 14 gauge wire...

Aluminum vent hood arrives: It's approximately 6'x2'x1'. Had a local Mechanical shop bend it up for me...

Replaced the old tired utility sink with with a stainless 4.5' x 2' (bin 18"x18") cleaning area...

Installed a RO System...

Setup a 72"x30" stainless table in the recently cleaned up brewery space...

Framing complete for electrical, RO water hose and an eventual pine board finish...

Required electrical purchased: (2) 30amp outlets, (1) GFCI 15amp outlet, (4) standard 15amp outlets, 10 & 14 gauge wire...

Aluminum vent hood arrives: It's approximately 6'x2'x1'. Had a local Mechanical shop bend it up for me...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)