Okay thanks for update.

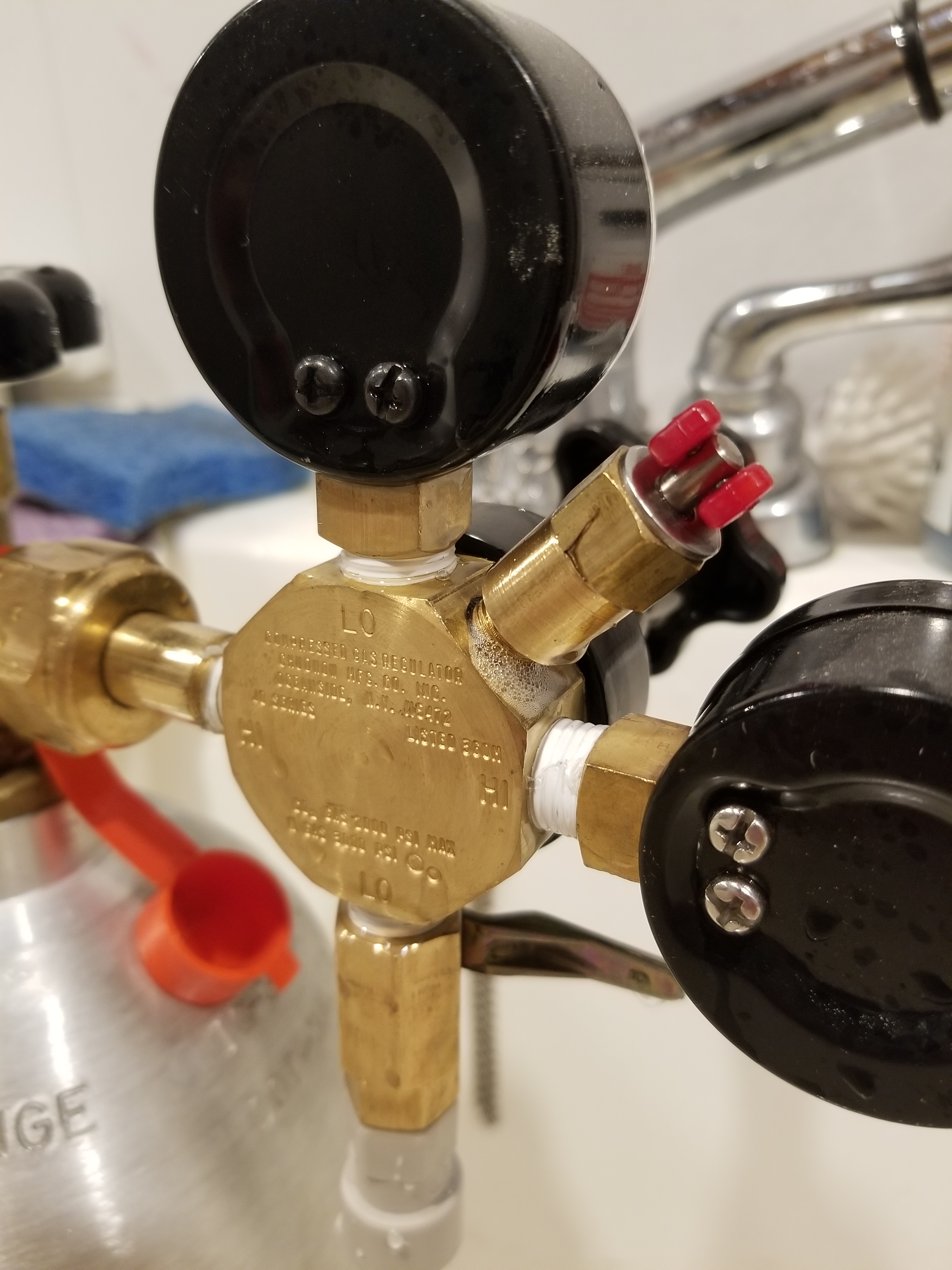

So if valve from cylinder off, but had been on, the low gauge reads the setting you have for the kegerator.

High gauge reads the tank pressure but now isolated as the cylinder is off.

If gas is being used either because beer is being drawn, or carbonating ( as system balancing out) then it will move past your non return valve to the beer side.

The high pressure valve drops as it supplies this gas ( but it only needs to supply a bit ) so it's a slow process.

So it might be okay. If you disconnected the gas end to the kegerator ( with ball lock ? ) then as long as the ball lock and connectors, non return valve and join to regulator not leaking that would identify more. IE it might stay higher for the high pressure gauge for longer as no losses south of it.

Not sure if I have explained my logic well here.

But as it stands you have an open system that you are testing for leaks and the only way to check the regulator and connections is to isolate it as much as possible and then work away from it hunting for any leak. If one exists.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)