Here is an update from yesterday's brew day, Our system is definitely getting more stable.

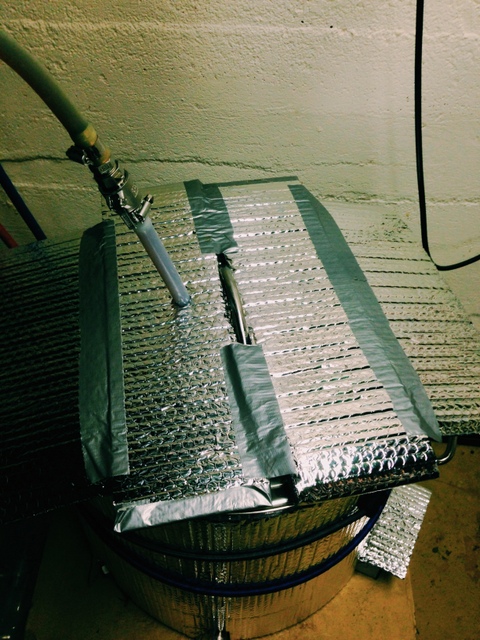

As you can see from the photos, we added Reflectix (2 layers) to the brew pot. Not surprisingly, this provided enough insulation that the element did not need to fire that often. We also made a hat for the lid. We put the recirc hose in the center of the mash (had previously been putting it on the side, opposite the pickup tube). I think this significantly helped recirculate the hot wort. The next step will be to drill a hole in the lid, so the lid can be all the way on.

The other big improvement was the 16" aluminum pizza screen. I made legs for it with 2.5" machine screws, washers, and finishing nuts. $2.25 per nut! I am relieved to say the screen did not collapse, though the screen is clearly deformed after one use. The legs were placed strategically around the element, and above the pickup tube. The big gaps in the spacing of the legs is because the screen rests on the fittings for the element and the valve. The tabs are a stainless brace, cut in half, to wedge the screen against the sides of the pot, to keep the screen from moving side to side.

The most interesting finding was that we had a vacuum lock throughout the mash. That is presumably why the screen is deformed. We had good luck with the pump running at about 50%, the bag was firmly stuck in place, but we did not drain all of the wort from underneath the screen and we did not have cavitation. Yambor44, the lid was more than a little open. I think the issue is the concrete oatmeal created by the fine mesh bag and the double crushed grain. I wonder if a slightly more coarse bag would allow the wort to flow more easily?

We managed to hold the mash between 151-153 pretty easily, though still with occasional stirring, albeit less stirring than before. We still need to move the RTD to the pump output, to minimize the temperature differences. As it stands, the SV needs to be a few degrees higher than our target mash temp.

Finally, I think we will ditch the pickup tube. I'm not sure it is doing anything except making it easy to pickup trub. We haven't had great luck whirlpooling, but the gunk does settle to the bottom pretty quickly. I'm thinking that without the tube, the valve will sit high enough above the trub after letting it rest for 15 minutes. There's always one more thing to experiment with...

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)