11/29/13 update

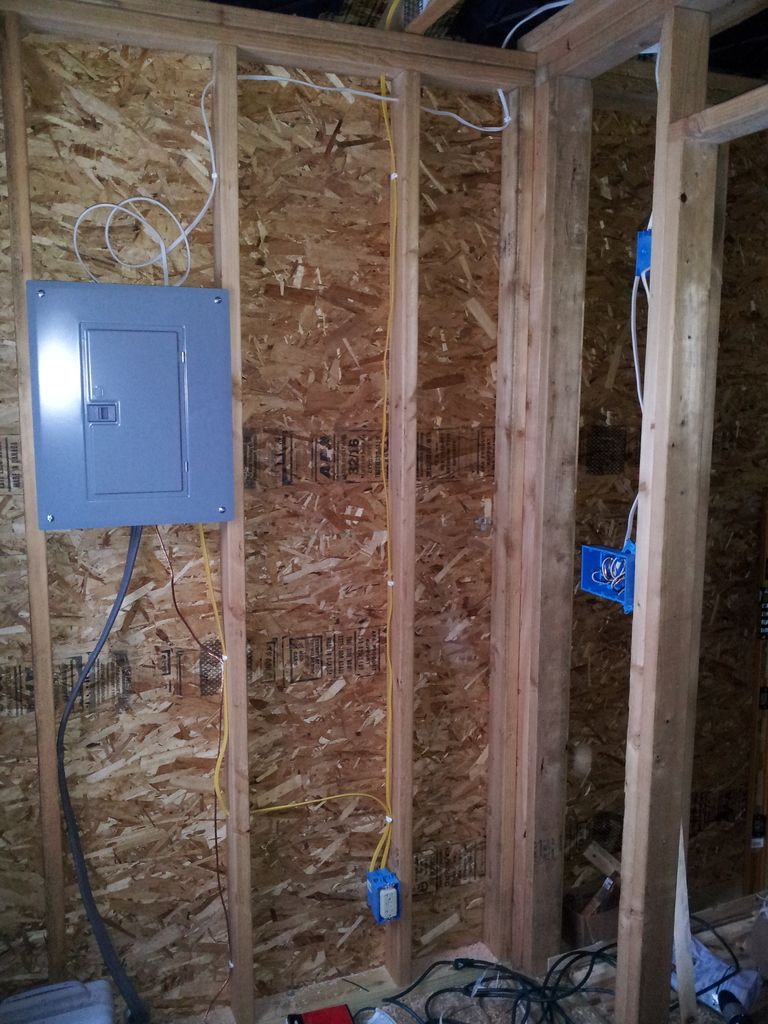

started interior electrical work. as you walk in the exterior door, the panel is on the left wall, such that it is 'covered' when the door is opened. i don't have any plans for expansion so i went with a flush mounting. at the bottom of the panel, you can see the incoming uf feeder. adjacent to that is the bare grounding electrode conductor connected to the ground rods outside. the yellow cable on the right is the 20 amp circuit for the convenience receptacles. there is one receptacle in the changing room (bottom of photo) and the cable continues up over the changing room to the wall opposite the photo, where it connects to the exterior receptacle.

the white cable coming out the top is a 15 amp circuit for lighting. the two blue boxes on the right are in the shared wall with the hot room (that's the hot room door opening on the far right). the upper box is to serve the light in the hot room. the lower box is a three-gang box in the changing room for the the lights: hot room, changing room and exterior:

started interior electrical work. as you walk in the exterior door, the panel is on the left wall, such that it is 'covered' when the door is opened. i don't have any plans for expansion so i went with a flush mounting. at the bottom of the panel, you can see the incoming uf feeder. adjacent to that is the bare grounding electrode conductor connected to the ground rods outside. the yellow cable on the right is the 20 amp circuit for the convenience receptacles. there is one receptacle in the changing room (bottom of photo) and the cable continues up over the changing room to the wall opposite the photo, where it connects to the exterior receptacle.

the white cable coming out the top is a 15 amp circuit for lighting. the two blue boxes on the right are in the shared wall with the hot room (that's the hot room door opening on the far right). the upper box is to serve the light in the hot room. the lower box is a three-gang box in the changing room for the the lights: hot room, changing room and exterior:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)