VirginiaHops1

Well-Known Member

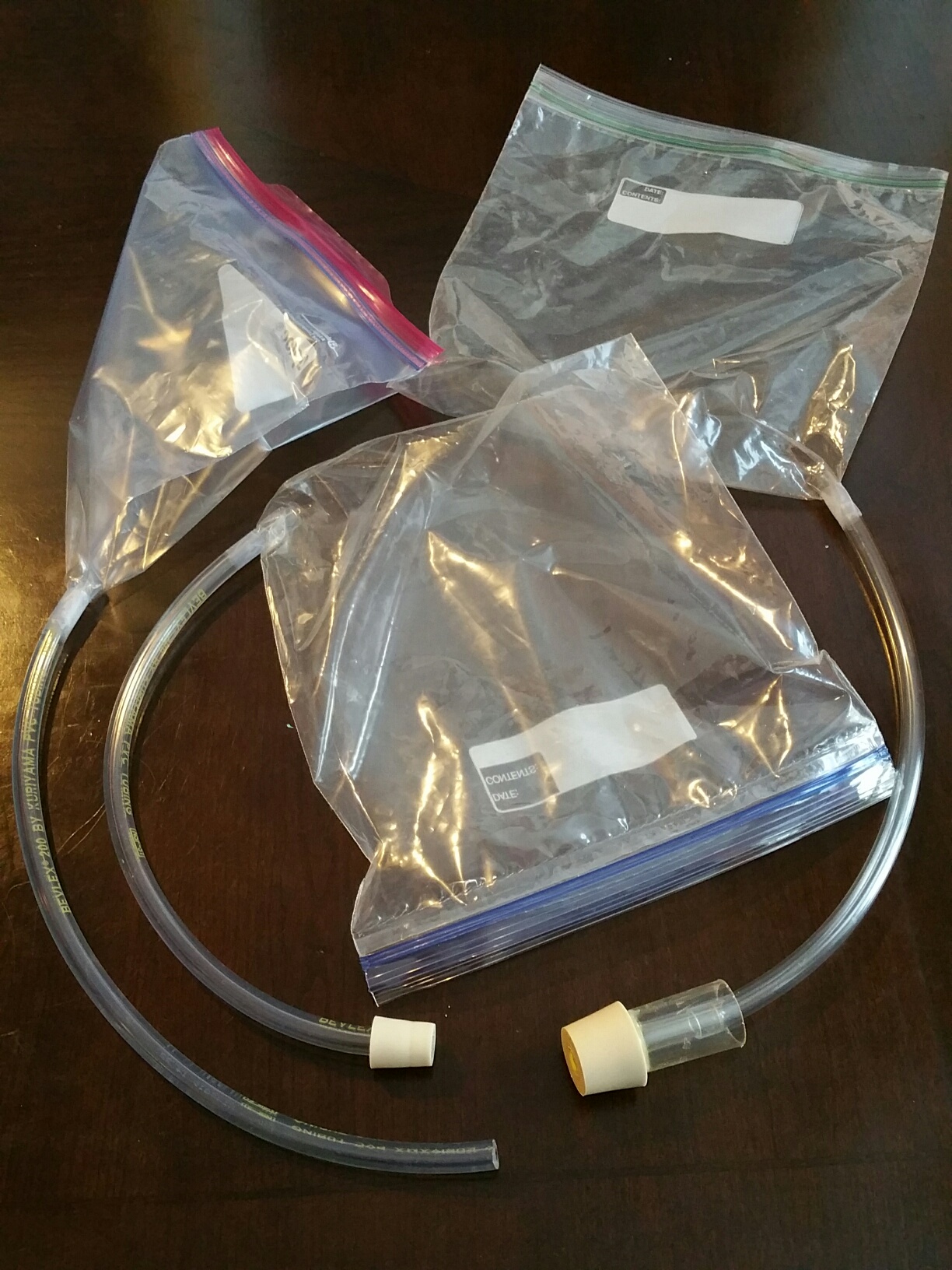

I stopped cold crashing to avoid possible oxidation but I recently tried doing a closed transfer to keg which completely went to hell thanks to clogged keg inlet, so I'm considering crashing again to try to make the transfer easier. I know about the balloon method, to feed CO2 back in during crash. What about using a really long blowoff tube? The tube would fill with CO2 during fermentation, then during crash that would get sucked backwards. I would just need a long enough tube so the liquid didn't make it to the fermenter. I just ordered 10 foot of tube I was going to cut up and use as blow-off. Anyone done this? I'm sure the entire 10 feet isn't needed but definitely want enough so my Starsan doesn't end up in the beer.