Just a teaser at the moment. This is a 2-vessel brew stand which is more or less automated to the goals below. The controller is an Arduino Mega.

Goal of stand

Planned activities for the next 3-ish months

Planned posts in no particular order

Until then... 'Merica

Goal of stand

- load grain

- enter recipe

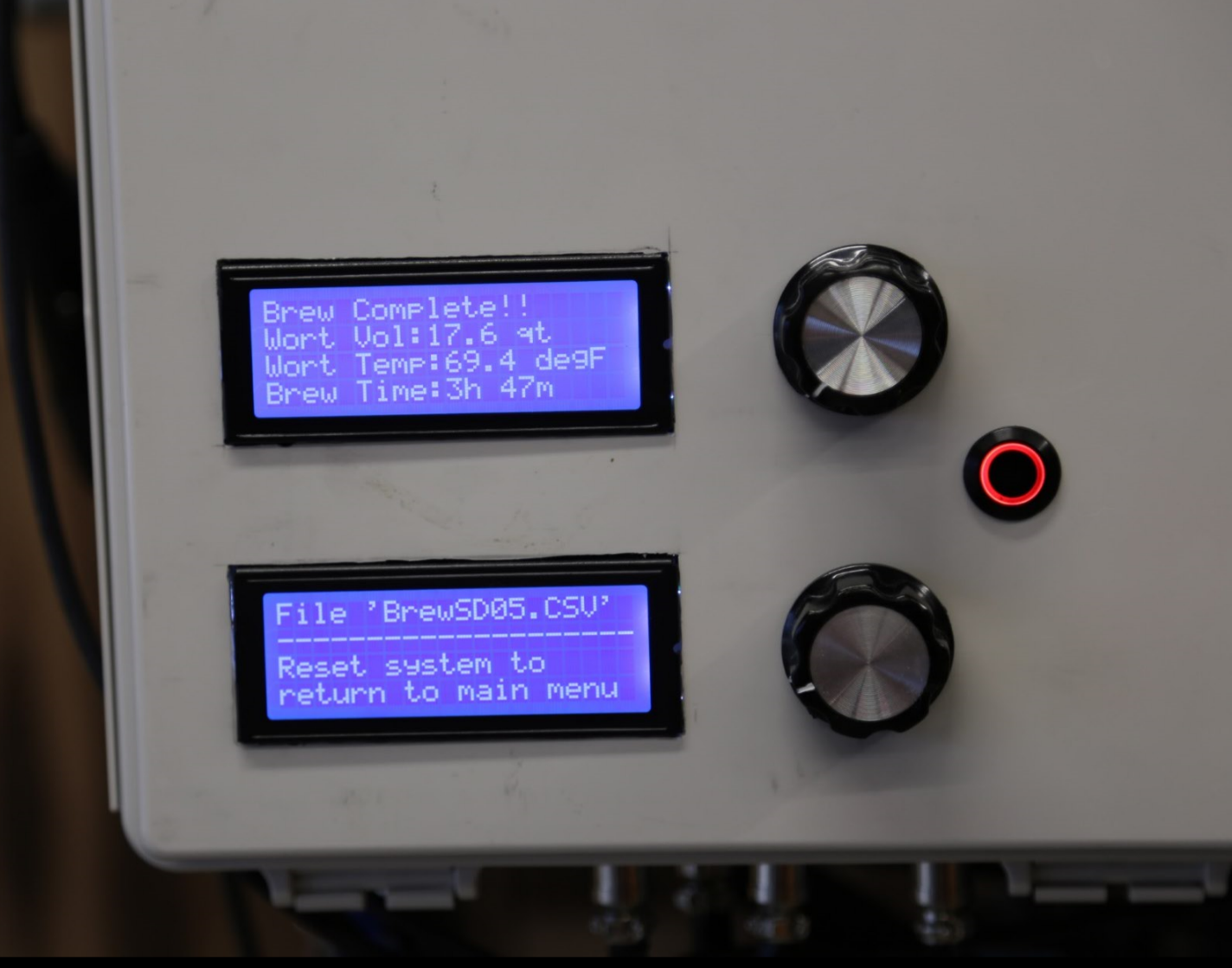

- return to find a carboy with cooled wort ready for yeast

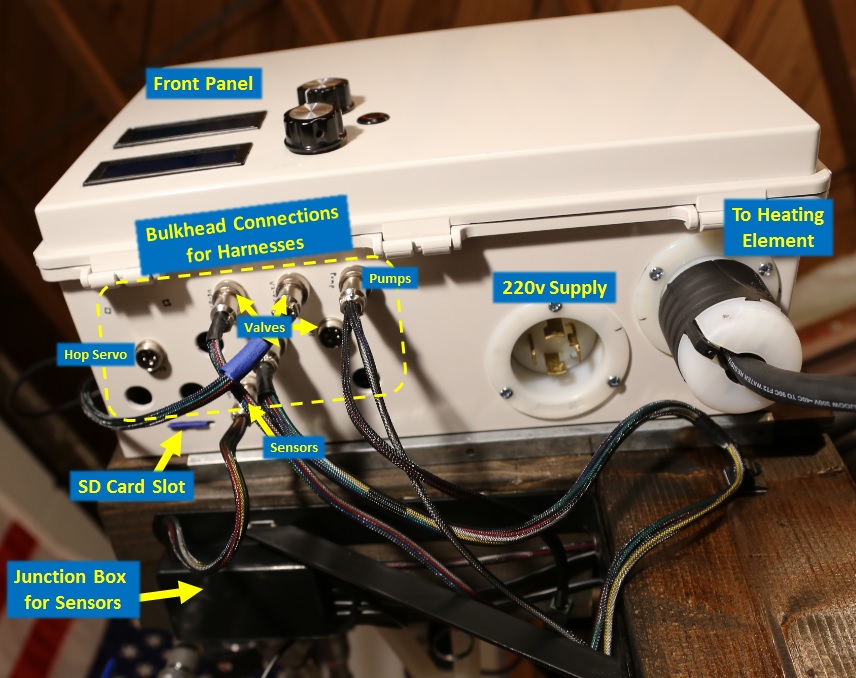

- all sensor data & key variables from session logged to SD card for post mortem

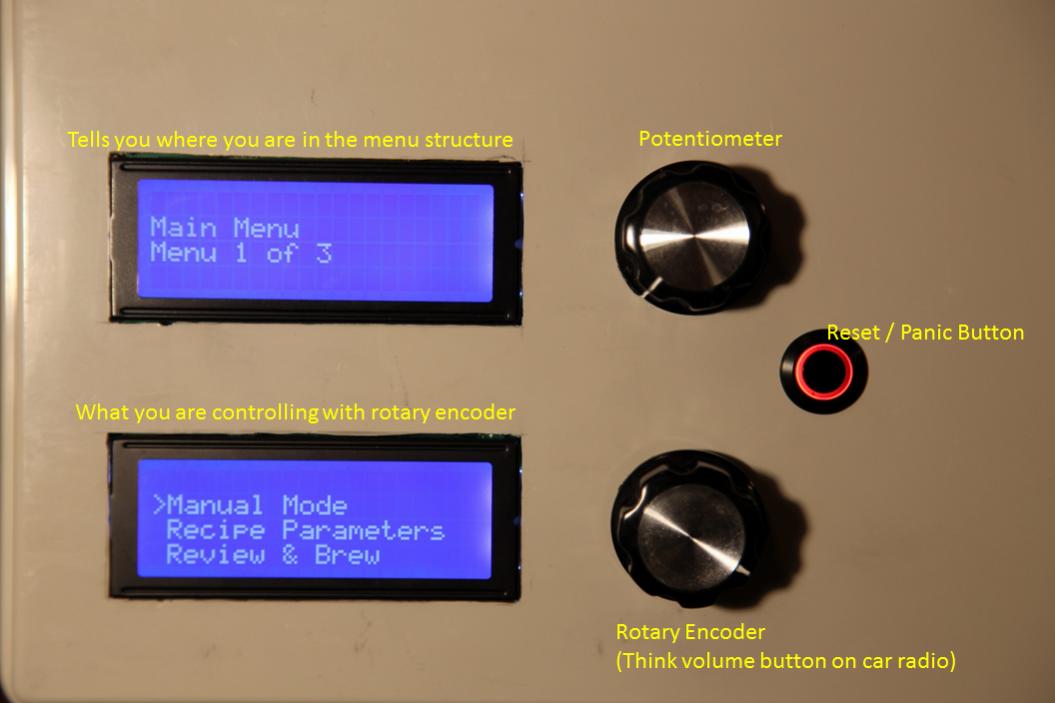

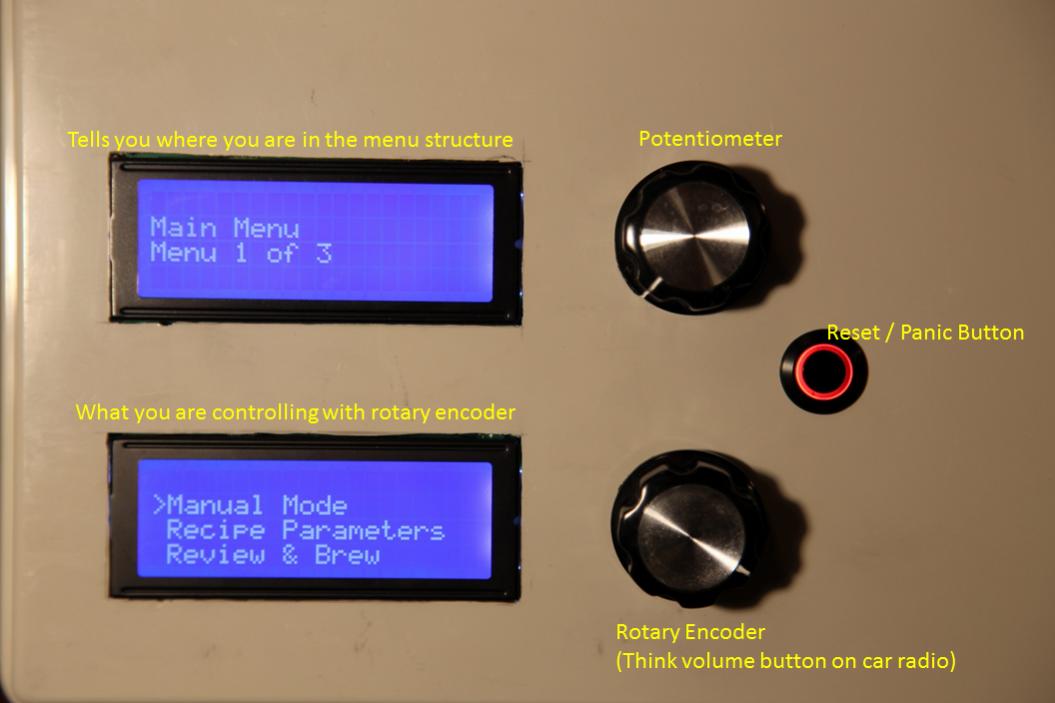

- user interface to monitor progress & provide inputs to system

- easy cleaning

Planned activities for the next 3-ish months

- Calibrating the water level sensor this week -- Good enough for initial testing. Will improve later

- Connecting to house water supply this weekend (followed by fixing leaks

) -- 1x v.slow leak so far

- Simulating brew sessions for a couple more weeks (i know there are bugs hiding in there)

- Moving to a new-to-me home (no progress for a month)

- Hopefully brewing in November

Planned posts in no particular order

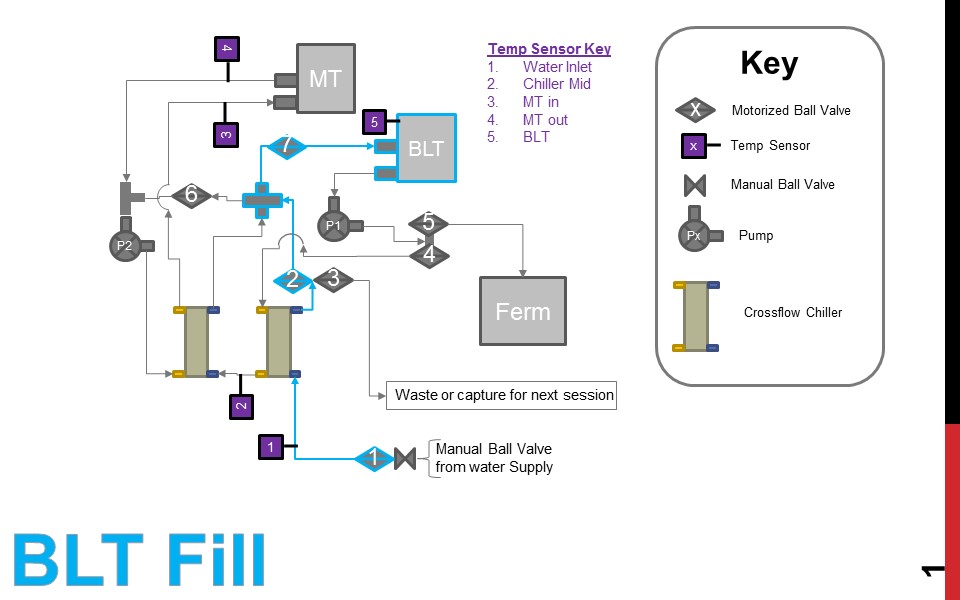

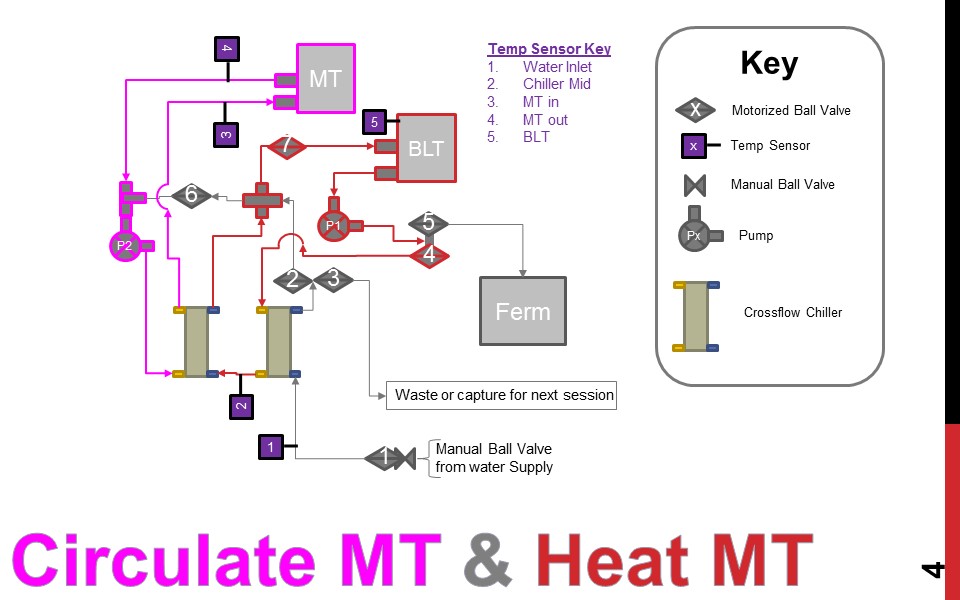

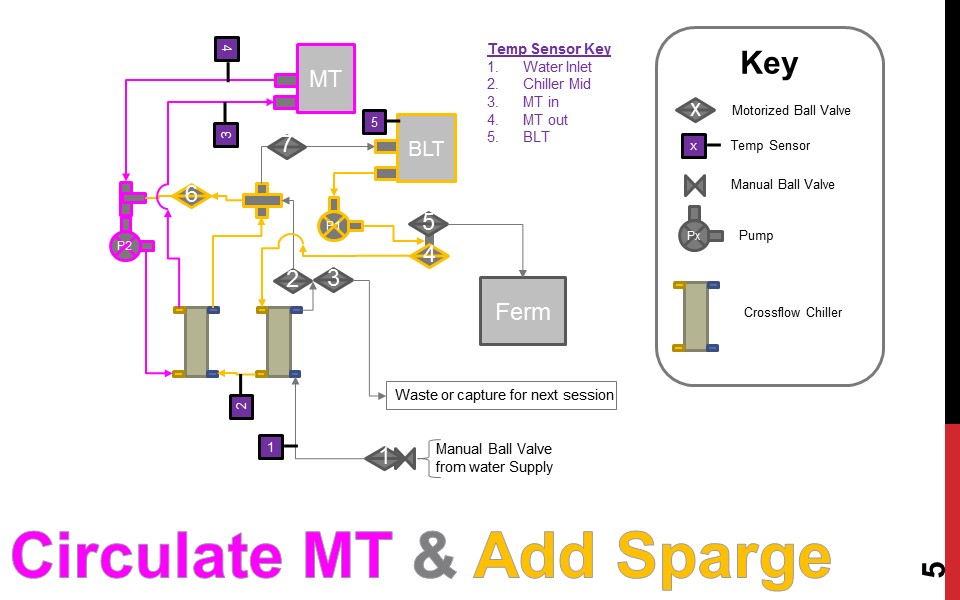

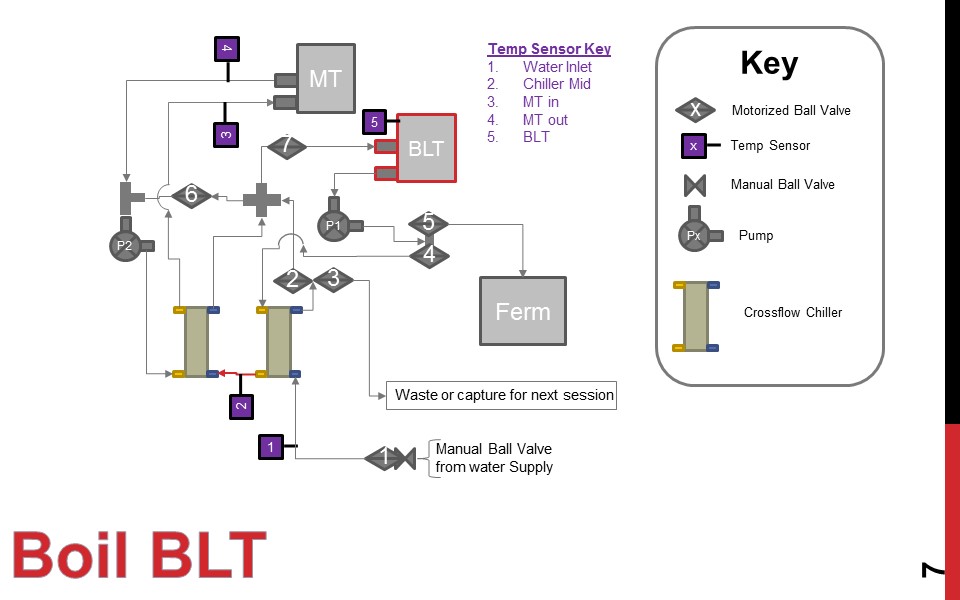

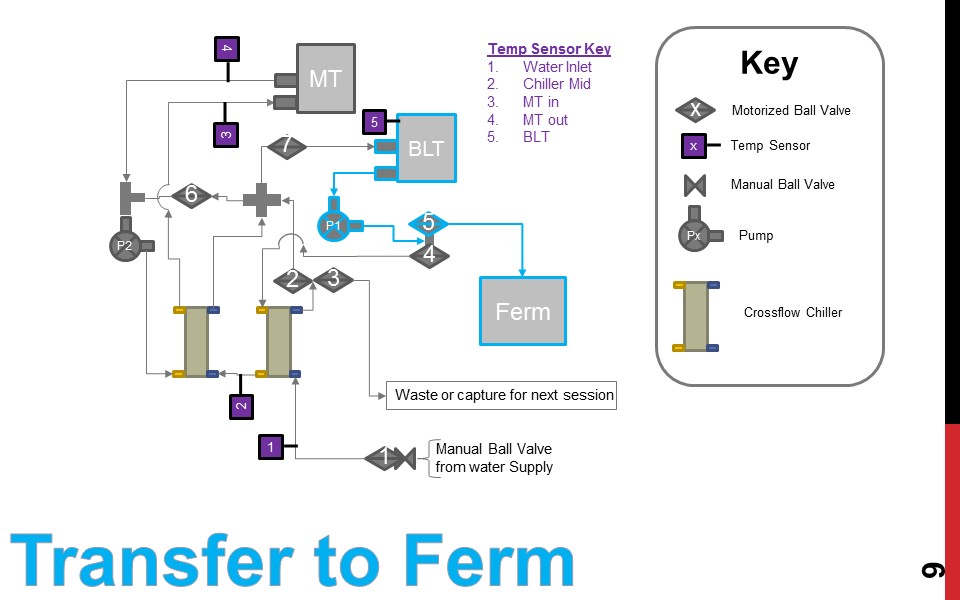

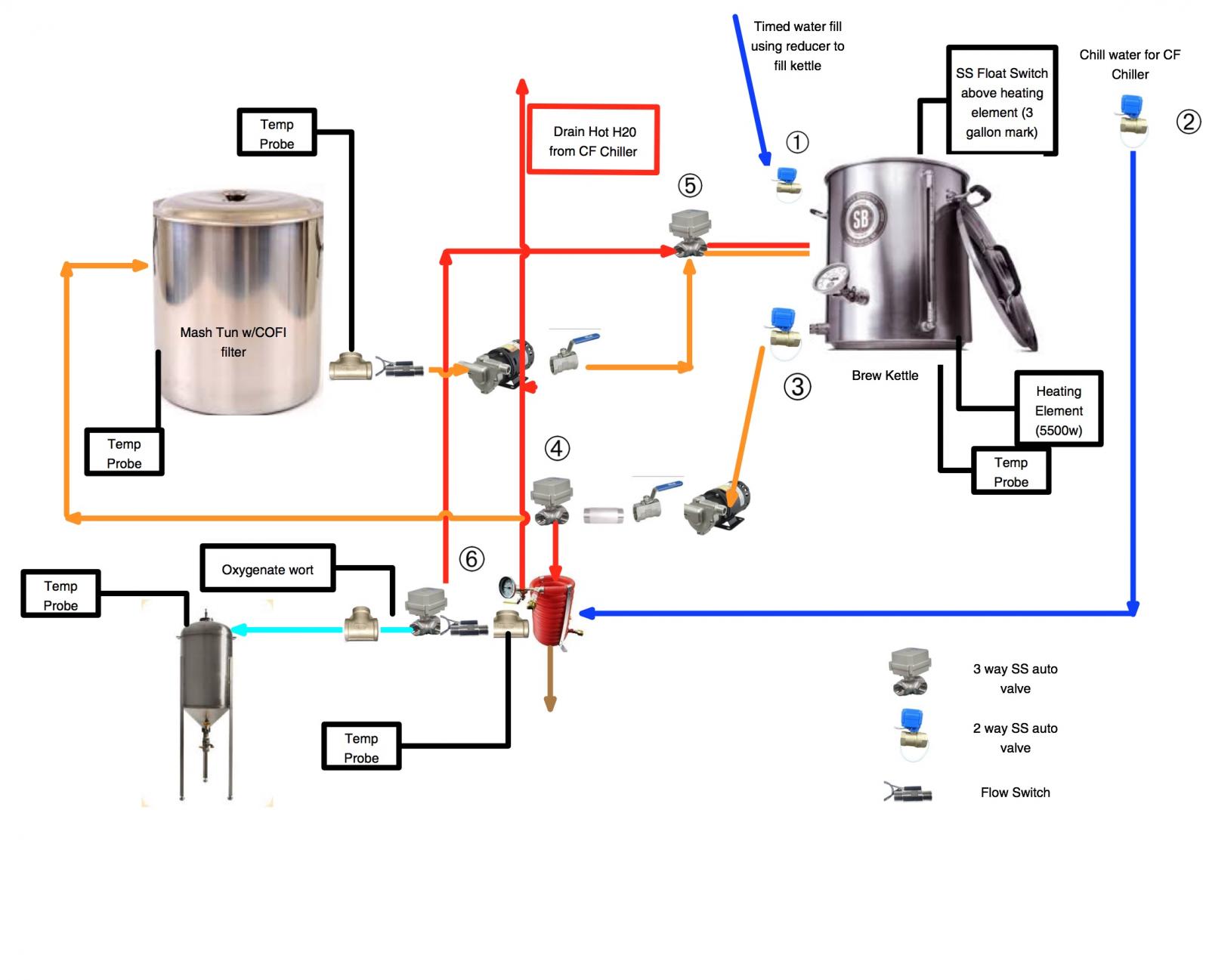

- Overall layout & process flow -- Posts 7,8,9

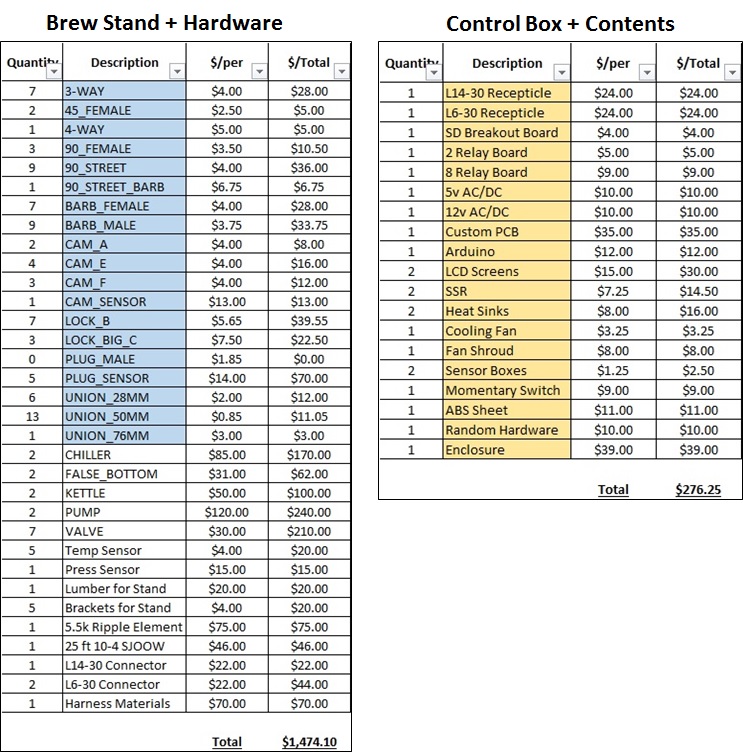

- BOM and $$$ -- Post 15

- Controller & electrical enclosure build -- Post 16

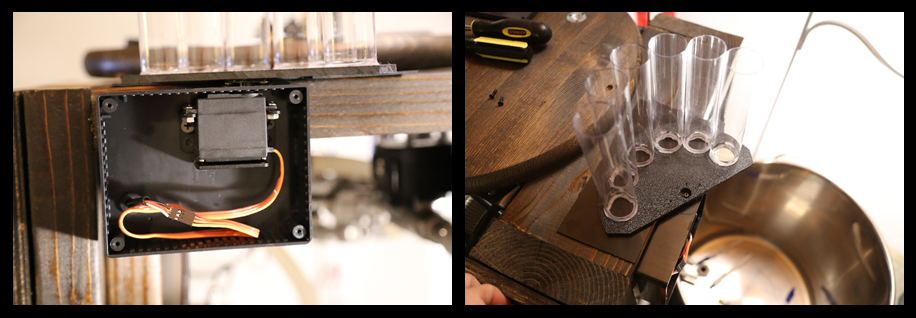

- The brew stand & associated hardware

- Sensor calibration & accuracy

- Open issues and requests for help on things that aren't as good as I would like

- BREW DAYS!

Until then... 'Merica

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

. I think I will be able to automate a cleaning cycle with exception of the part where I scrub a bit during the 3rd fill/rinse cycle.

. I think I will be able to automate a cleaning cycle with exception of the part where I scrub a bit during the 3rd fill/rinse cycle.