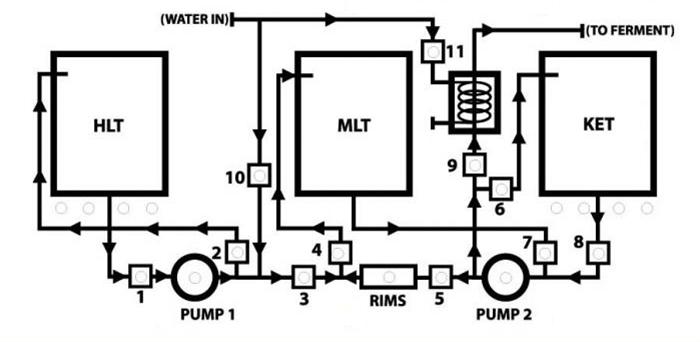

One of the fun aspects of automation is designing your valves and flow diagrams. I would like to start a thread should valve layouts and system designs. If you have any to contribute please do so. All that I will post are references to ones I have found online. I am currently in design phase of my own system just gathering parts.

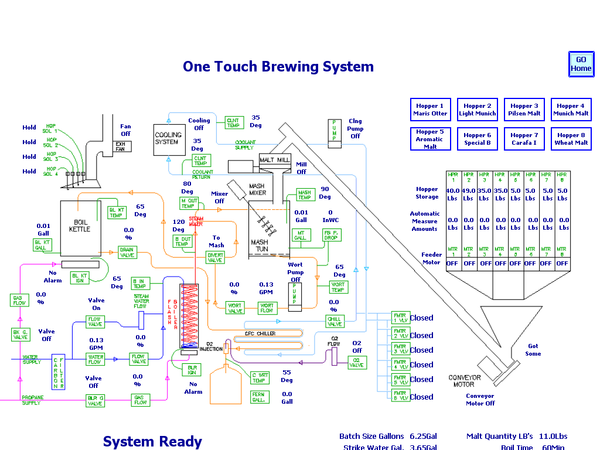

http://www.brewtroller.com/downloads/btbrew.pdf

http://www.brewtroller.com/downloads/btbrew.pdf

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)