smata67

Well-Known Member

Last edited:

Thank you. Was grabbed by the title and knew this had to be done. You beat me to the punch. Kudos.

Makes me want to give up drinking or drink more.

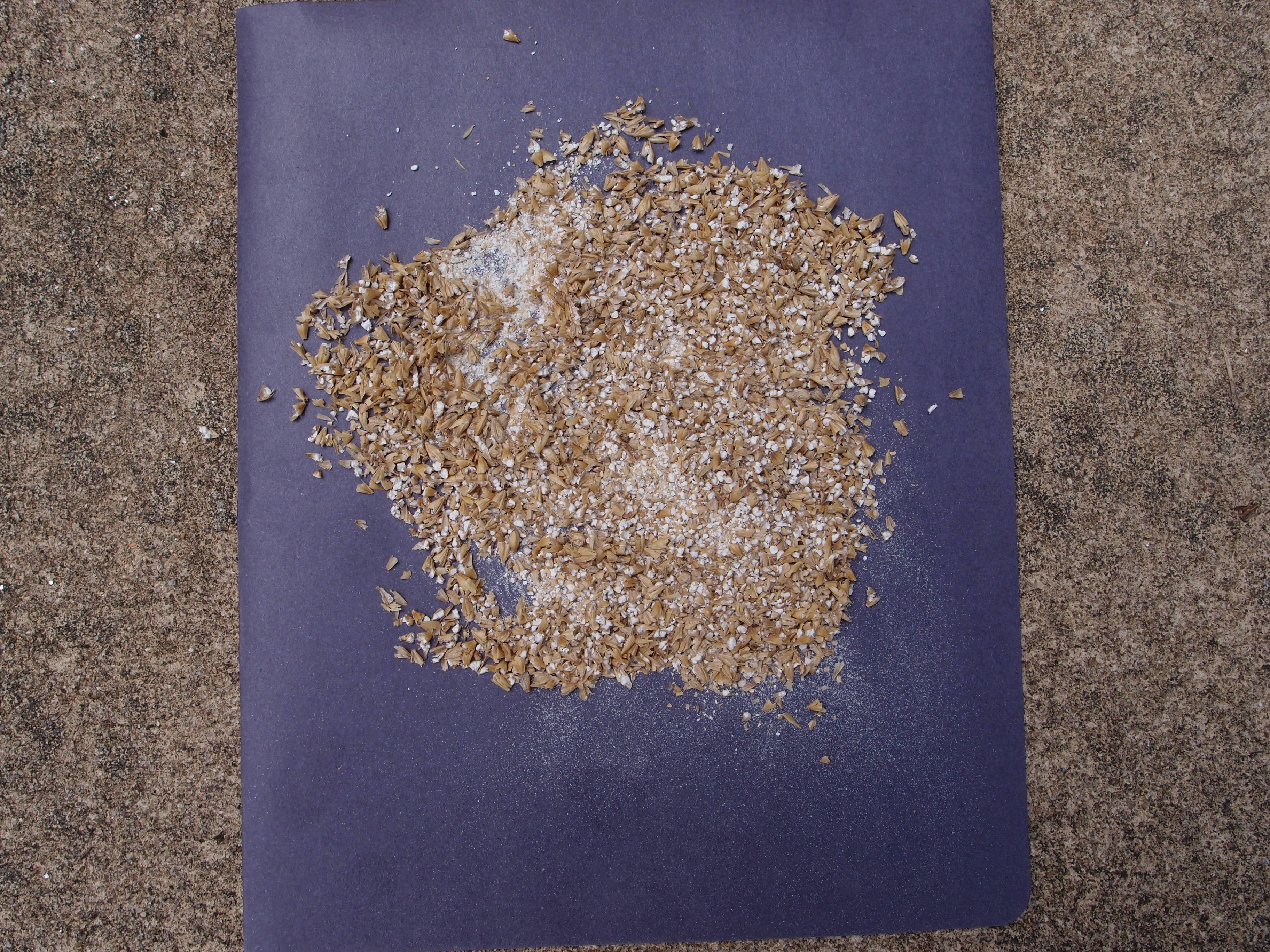

- I get 82% and set mill a credit card thick.. = .030 inches. I have a unique mash tun that will not get stuck. Send me an email and I will send you photos etc as I have no idea how to post photos here.

Contrary to what is commonly stated on here, grind doesn't cause poor efficiency as long as all grains are broken open. Well, kind of. Providing you mash for long enough, preferably with a rest at the higher end of the conversion range (mainly to help extraction of starches from the grain), you should hit close to 100% conversion efficiency. That may well take longer than the typical 1 hour mash though. My first piece of advice for anyone with efficiency issues (providing the crush isn't leaving whole grains) is to mash until the mash is complete rather than mashing to a timeframe.

And usually full conversion is done in well under an hour. Maybe as little as 15 minutes.