friskysquirrelbrewing

Member

- Joined

- Sep 21, 2016

- Messages

- 6

- Reaction score

- 3

Long time listener, first time caller... I figured I would post about my automated brewing project that I recently completed. Hopefully others may find it slightly useful.

I had been brewing 5 gallon batches using the BIAB method for about 2 years when I stumbled upon The Electric Brewery (http://www.theelectricbrewery.com/). Something about it intrigued me. We had been using a rusty turkey burner to heat, then wrapped in towels to mash, followed by batch sparges that required hoisting the (often times very heavy) bag above the bottom of the pot. The Electric Brewery seemed an elegant solution in comparison, and could also easily be implemented as a 10G system, which would save time.

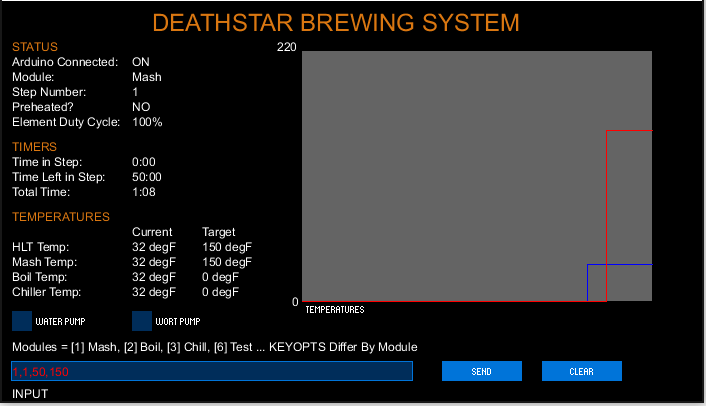

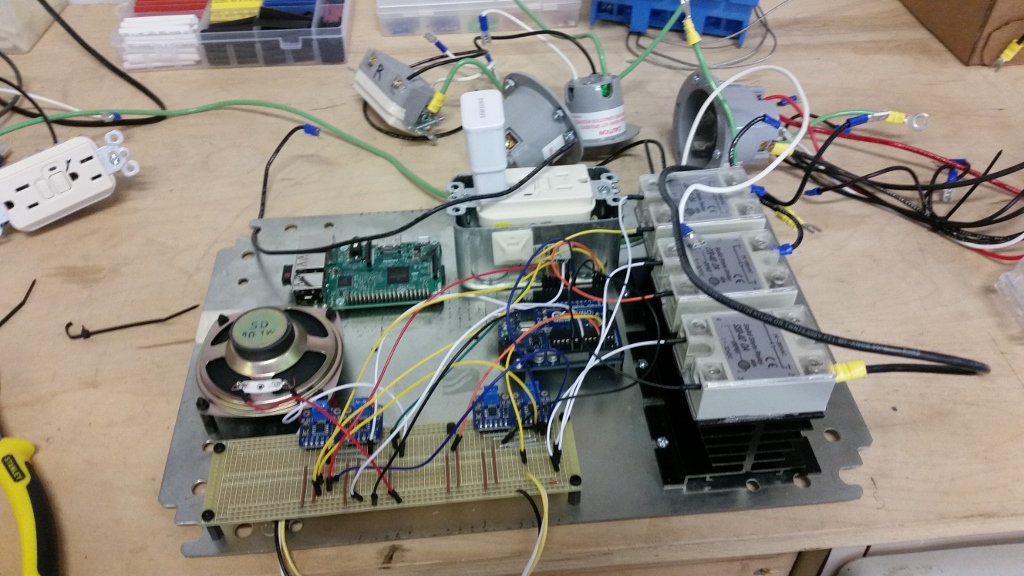

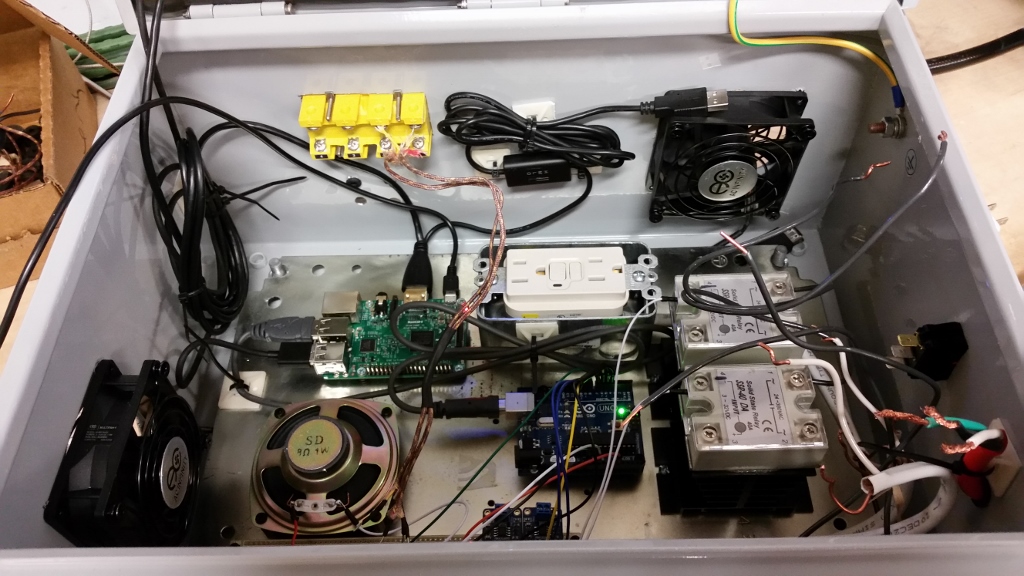

I am not an electrician/electrical engineer, nor could I really afford the $2300 assembled panel cost from the website, so I decided to go about it slightly differently. Since I am one of the weirdos who actually likes programming, and I had some experience using Arduino for other little pet projects, I opted to use that as the basis for my system. It really turned out to be quite a simple solution: a Rasberry Pi, which provides a graphical user interface, would drive and Arduino, which is relatively easy to program, which would in turn control three solid state relays (one for heating element, one for a mash pump, and one for a water pump). So, the project began ... but before you keep reading, here are some pictures of the final setup to keep you interested ...

If you are familiar, you will notice that most of the hardware looks an awful lot like the Electric Brewery. That's because it is. Only change was really in the controller.

I had been brewing 5 gallon batches using the BIAB method for about 2 years when I stumbled upon The Electric Brewery (http://www.theelectricbrewery.com/). Something about it intrigued me. We had been using a rusty turkey burner to heat, then wrapped in towels to mash, followed by batch sparges that required hoisting the (often times very heavy) bag above the bottom of the pot. The Electric Brewery seemed an elegant solution in comparison, and could also easily be implemented as a 10G system, which would save time.

I am not an electrician/electrical engineer, nor could I really afford the $2300 assembled panel cost from the website, so I decided to go about it slightly differently. Since I am one of the weirdos who actually likes programming, and I had some experience using Arduino for other little pet projects, I opted to use that as the basis for my system. It really turned out to be quite a simple solution: a Rasberry Pi, which provides a graphical user interface, would drive and Arduino, which is relatively easy to program, which would in turn control three solid state relays (one for heating element, one for a mash pump, and one for a water pump). So, the project began ... but before you keep reading, here are some pictures of the final setup to keep you interested ...

If you are familiar, you will notice that most of the hardware looks an awful lot like the Electric Brewery. That's because it is. Only change was really in the controller.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)