beerBAHAMA

Member

Hello everyone, I'm the owner of a small beer bar in Japan.

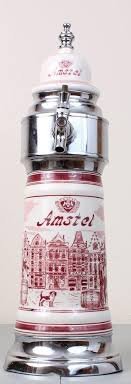

We are still using a German draft beer tower from around the year 1900 — it’s fully functional and serving customers every day.

I'm wondering if there are any other bars, breweries, or collectors who are still actively using antique draft towers from that era.

Have you seen similar equipment still in use?

(If allowed, I’ll share a photo in the comments.)

Thanks in advance!

We are still using a German draft beer tower from around the year 1900 — it’s fully functional and serving customers every day.

I'm wondering if there are any other bars, breweries, or collectors who are still actively using antique draft towers from that era.

Have you seen similar equipment still in use?

(If allowed, I’ll share a photo in the comments.)

Thanks in advance!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)