After six months or so of reading how homebrewers have tackled building an esthetically pleasing, reasonable costing and functional way of serving their precious homebrew, I have completed a beer tower and trunk line and thought I'd share the pictures here. My main design criteria were:

- Six beers on tap

- Two beers 'On deck' for a total of eight kegs

- No lifting kegs in and out of a chest freezer to minimize pulled muscles and back injury

- Quiet operation (as this tower is part of a basement bar)

- Efficient trunk line cooling

In the past, I have built two four-keg kegerators before, one freezer based and one refrigerator based and I have a Kegco XCK-1B four tap commercial unit. The Kegco does the job but is designed for stand alone (not under counter, built in, use and is very noisy. After a lot of research and talking with other homebrewers I settled on the following configuration:

- Two Komos V2 kegerators sourced from BrewHardware.com

- Six line trunk with a 3/8" copper core. Maximum length is 13' from furthest keg to tap

- Pumped water to chill the trunk line. Reservoir in one of the kegerators.

- 5mm EVABarrier line for beer from HomeBrewHardware.com

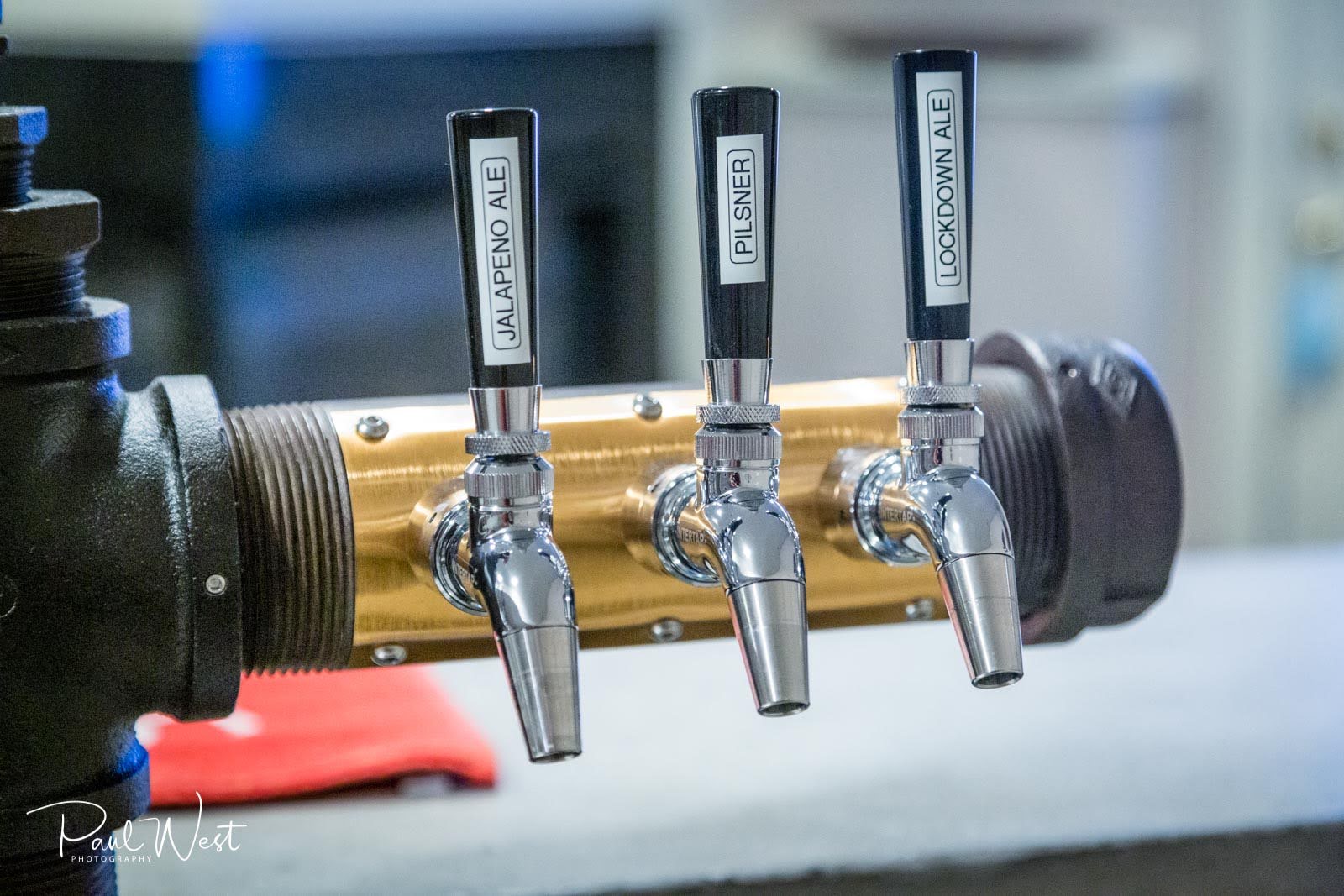

- 2.5" Black Iron Beer Tower. 'T' Configuration. Parts sourced from SupplyHouse.com

- 20" Drip tray with dual glass washers

- Intertap faucets with removable nozzles and spring closure sourced from BrewHardware.com

- John Guest/Duotight beer and CO2 connections

The tower construction started seven days ago and we had our first family test of he system this weekend. It all worked well although I feel that the beer line chilling needs some optimization. As a result I have instumented the trunk lie and filled a keg with water to test the delivery temperatures. There is only 2.6 Fluid ounces of beer in a 13' run of the 5mm EVA pipe so the trunk line cooling does not significantly affect the temperature of a glass of beer. It does however contribute to the foaming. Currently, as designed with no tweaking, the beer foam is manageble. A little high but certainly on a par with the Kegco commercial unit I have which uses a chilled air feed to the tower.

I will post the pictures below and I hope this helps others in the design and build of their beer tower designs and build.

Paul

- Six beers on tap

- Two beers 'On deck' for a total of eight kegs

- No lifting kegs in and out of a chest freezer to minimize pulled muscles and back injury

- Quiet operation (as this tower is part of a basement bar)

- Efficient trunk line cooling

In the past, I have built two four-keg kegerators before, one freezer based and one refrigerator based and I have a Kegco XCK-1B four tap commercial unit. The Kegco does the job but is designed for stand alone (not under counter, built in, use and is very noisy. After a lot of research and talking with other homebrewers I settled on the following configuration:

- Two Komos V2 kegerators sourced from BrewHardware.com

- Six line trunk with a 3/8" copper core. Maximum length is 13' from furthest keg to tap

- Pumped water to chill the trunk line. Reservoir in one of the kegerators.

- 5mm EVABarrier line for beer from HomeBrewHardware.com

- 2.5" Black Iron Beer Tower. 'T' Configuration. Parts sourced from SupplyHouse.com

- 20" Drip tray with dual glass washers

- Intertap faucets with removable nozzles and spring closure sourced from BrewHardware.com

- John Guest/Duotight beer and CO2 connections

The tower construction started seven days ago and we had our first family test of he system this weekend. It all worked well although I feel that the beer line chilling needs some optimization. As a result I have instumented the trunk lie and filled a keg with water to test the delivery temperatures. There is only 2.6 Fluid ounces of beer in a 13' run of the 5mm EVA pipe so the trunk line cooling does not significantly affect the temperature of a glass of beer. It does however contribute to the foaming. Currently, as designed with no tweaking, the beer foam is manageble. A little high but certainly on a par with the Kegco commercial unit I have which uses a chilled air feed to the tower.

I will post the pictures below and I hope this helps others in the design and build of their beer tower designs and build.

Paul

Attachments

Last edited: