For some reason, I can't quote anything from this thread .... weird.

I realized I never changed my location so I did that. For those of you who have known me for a while - I've moved. We've literally "bought the farm" down in rural Kansas.

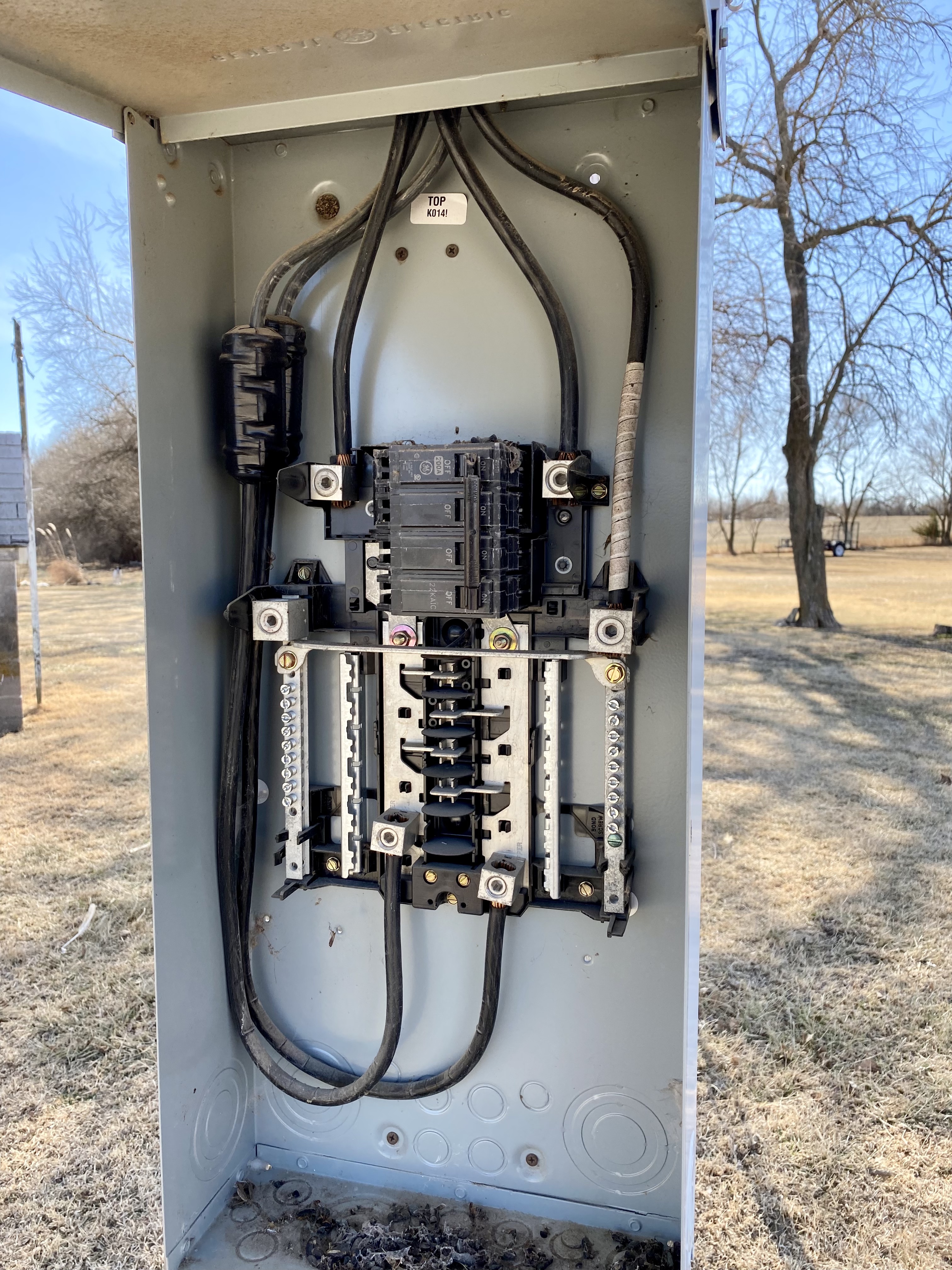

The last person to touch this (seems like only a few years ago) added some outlets to this load box. He was a licensed electrician who should lose his license. So, hiring an electrician, other than him having a taller ladder and the right tools, hardly seems like the safe bet. Even if I do hire an electrician it looks like I need to learn about what's wrong with this setup. That allows me to gauge his approach and be an informed consumer.

Believe me, I appreciate the cautionary tales. In my path to get where I am, I did a stint installing building controls. At that time (no idea how it is now) there were no unions for that part of commercial construction, so we were left to learn things the hard way in some cases. We did some plumbing, some electrical, and some programming depending on the day. I had my favorite screwdriver go off like a flashbulb when I was working on a VFD. So, yeah, I get it. I don't want to die.

I am not going to tell you I know as much as a good electrician. I am going to tell you once I know what is supposed to be done, I can do it safely.

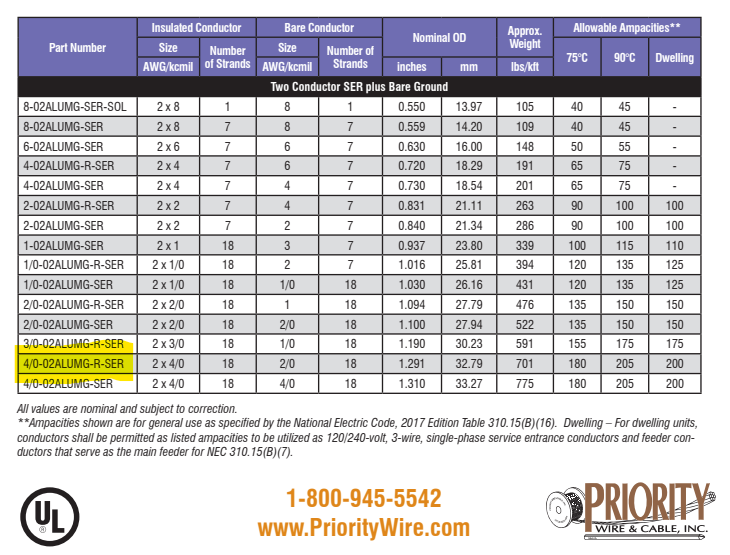

I'm also aware of the NEC. That's why I was looking for "the words" so I would know what to look up. Reading the NEC is not really as engaging as Steven King, so having the right terms to go searching for will help me find what I need. I also appreciate the qualified advice I've received here. A one-liner from an experienced craftsman is worth its weight in gold. Just ask

@day_trippr: I learned the hard way to listen to him. When he says "Vaya con Dios" I know I am bout to screw something up.

I think my biggest problem in this project will be that I can fix one thing but the next thing up the line will be wrong. I've had these sorts of projects before. It seems like I'm going to have to survey the entire electrical system here and see what I can isolate before I can renovate it. Yay, rural living! It's looking like a trencher for the tractor will be a good investment (yes, that's a joke.)