Noob_Brewer

Well-Known Member

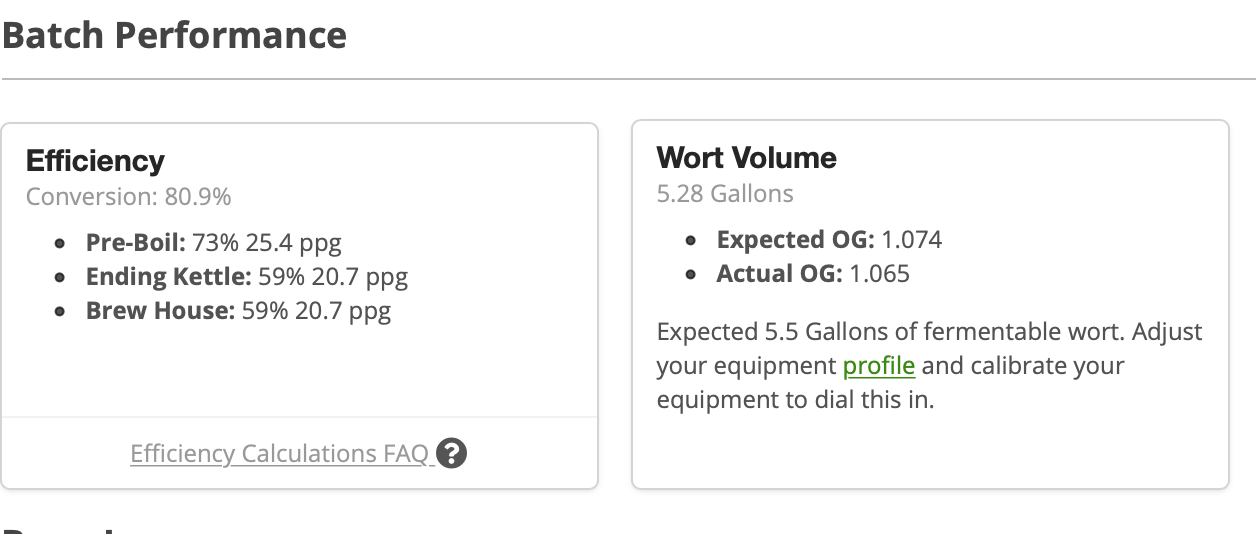

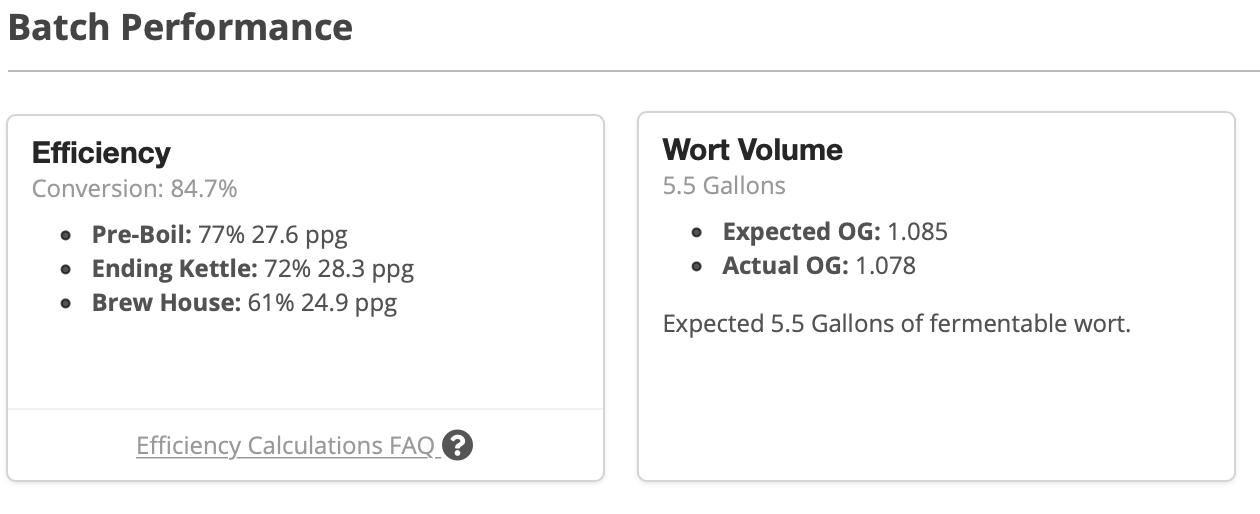

Yes I am sparging. But my sparge process is different than how the anvil foundry is intended. Ive posted pics in this thread that I have ditched the malt pipe and just use the bag inside the kettle with a brewzilla false bottom. So to sparge, I sparge with the bag in place while doing a slow drain/pump of the wort to a second kettle. Once the wort line gets to the top of grain bed, I gently and slowly add one quart at a time to the top of the grain bed of sparge water. Im convinced that sparging with the bag in place without disturbing the grain bed at all, gets a slightly better sparge than lifting the bag full. Nonetheless, after about 10minutes of the last sparge quart being added to grains, I lift the bag to gravity drain while pump the wort back to the foundry. My mash/lauter efficiency yesterday with hitting preboil volume was 82.4%.That wort looks great! So are you sparging then? If yes I'm curious about your mash efficiency since you didn't have to squeeze the bag.

To get that clear wort in the end, I think this is a combination of 3 things: 1) If I don't have to bag squeeze, there is less gunk going to the BK, I find that one good squeeze generally still gets clear wort out but any more and the gunky/cloudy stuff starts coming out, 2) I use whir floc on EVERY beer, even NEIPAs - they still turn out hazy at the end but not "murky" which I don't prefer, and 3) after I finished chilling yesterday at 2pm, I wheeled my cart over to the minifridge with fermenter, then attended to family "stuff". So at 5:30pm (3.5hrs later) it was nice and settled.

Yes, it does make for a longer brew day overall, but by the time 5:30 came along the ONLY things I still had to clean was the foundry and pump and the attached hoses. A one hour hot PBW cycle during dinner time was all that was needed. Ideally, I would love to be able to dump it all in the fermenter immediately, but with free roaming hops and other cold break, etc - it does take time to settle in that tall narrow foundry. So thats how I do it overall and being flexible with my time allows me to do it this way as well which may or may not be feasible for others.

Cheers

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)