Purchased this a few months ago and love it! However, I have been getting some pretty low efficiency on my last few batches (less than 60%). I don't have a mill, so I usually just have my LHBS crush for me at their standard crush setting. I'm assuming this is where my efficiency loss is coming from. Can anyone recommend what they crush their grains at using the anvil foundry to get good efficiency without having to deal with stuck mash? I'd like to try experimenting with a different size crush to see if that boosts my efficiency up. Ideally if I can stay in the 70% ^ range I'd be happy with that.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ANVIL FOUNDRY ALL-GRAIN BREWING SYSTEM

- Thread starter czmkid

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I would say .35" or below and some rice hulls to ensure good flow.

Last edited:

Noob_Brewer

Well-Known Member

Purchased this a few months ago and love it! However, I have been getting some pretty low efficiency on my last few batches (less than 60%). I don't have a mill, so I usually just have my LHBS crush for me at their standard crush setting. I'm assuming this is where my efficiency loss is coming from. Can anyone recommend what they crush their grains at using the anvil foundry to get good efficiency without having to deal with stuck mash? I'd like to try experimenting with a different size crush to see if that boosts my efficiency up. Ideally if I can stay in the 70% ^ range I'd be happy with that.

I have the 10.5g foundry and have now brewed 12 batches total. Im also a brand new brewer so those 12 batches are my first 12 batches ever lol. I think over 70% is definitely achievable and expected. I have sparged with all my brews so I can't speak to full volume no sparge efficiencies. I had one dud at 58% mash/lauter efficiency and have as high as 79% mash/lauter efficiency. But I think Ive settle in at 76% as my most consistent mash efficiency. While I have gotten 76% efficiency with larger crushes at .037-.040, the last 4-5 beers Ive been milling at .030". I do use a wilser bag inside the malt pipe so very little flour gets outside of the bag - if you don't have a bag, Im not sure .030 would be wise. After the first 20minutes of mashing and after I give the whole mash a good stir, I start recirculating but at a slow speed. It doesn't take much to maintain temps in the foundry. I stir the entire grain bed once every 20 minutes afterwards as well. I haven't gotten a stuck sparge with this grain mill setting yet and get good mash efficiency with grain bills that are very sticky (20-30% oats/wheat/etc. I do put in .75lb of rice hulls for every batch too. My last brew yesterday, I loaded the foundry with 17.5lbs of grain + 0.75lb of rice hulls (18.25lbs all together) and had a 1.75quart/lb water to grist ratio. It was a tight fit and very thick, but didn't get a stuck recirculation at all. My mash/lauter efficiency on this brew was 74.8% which I was pumped to get since I knew I was pushing the limits of the foundry's capacity.

I have the 10.5g foundry and have now brewed 12 batches total. Im also a brand new brewer so those 12 batches are my first 12 batches ever lol. I think over 70% is definitely achievable and expected. I have sparged with all my brews so I can't speak to full volume no sparge efficiencies. I had one dud at 58% mash/lauter efficiency and have as high as 79% mash/lauter efficiency. But I think Ive settle in at 76% as my most consistent mash efficiency. While I have gotten 76% efficiency with larger crushes at .037-.040, the last 4-5 beers Ive been milling at .030". I do use a wilser bag inside the malt pipe so very little flour gets outside of the bag - if you don't have a bag, Im not sure .030 would be wise. After the first 20minutes of mashing and after I give the whole mash a good stir, I start recirculating but at a slow speed. It doesn't take much to maintain temps in the foundry. I stir the entire grain bed once every 20 minutes afterwards as well. I haven't gotten a stuck sparge with this grain mill setting yet and get good mash efficiency with grain bills that are very sticky (20-30% oats/wheat/etc. I do put in .75lb of rice hulls for every batch too. My last brew yesterday, I loaded the foundry with 17.5lbs of grain + 0.75lb of rice hulls (18.25lbs all together) and had a 1.75quart/lb water to grist ratio. It was a tight fit and very thick, but didn't get a stuck recirculation at all. My mash/lauter efficiency on this brew was 74.8% which I was pumped to get since I knew I was pushing the limits of the foundry's capacity.

Looks like I might need to get a bag for the malt pipe if I want to do a finer crush to help efficiency. I also have never stirred the entire grain bed. I just rake the top 1/3 every 15 mins with the recirculating pump, so I may give this a shot as well.

What is your sparging technique with the foundry? Once my mash is over I have been bringing the temp up to 170 for a mash out. As soon as it hits 170 I pull the malt pipe up and lock it in. Then as the grains are draining I'll slowly pour my sparge water in. I have been leaving the perforated disc on the top as I pour to help allow it to trinkle in while sparging. Would there be a better sparging technique on this system that will yield better efficiency?

Last edited:

jlb307

Well-Known Member

So far I've only been able to make one batch on my 6.5, and the efficiency calculated by Brewfather was 73%, which surprised me. The grains were ordered crushed from NB, and they didn't look particularly fine.

I didn't use a bag, per se, but a while ago I bought some voile fabric sheer curtains from Wal-Mart and lined the pipe with that. That's what I used to do when I was strictly stove-top BIAB. Plenty of fabric to make into actual bags, but so far this has worked for me.

I didn't use a bag, per se, but a while ago I bought some voile fabric sheer curtains from Wal-Mart and lined the pipe with that. That's what I used to do when I was strictly stove-top BIAB. Plenty of fabric to make into actual bags, but so far this has worked for me.

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

I do use a wilser bag inside the malt pipe so very little flour gets outside of the bag - if you don't have a bag, Im not sure .030 would be wise.

Very helpful thread.

@Noob_Brewer - I don't have a Foundry, yet (undecided if I should sell my 15 gal kettle/MT/pump/NG burner) but was wondering if you could give more info on what the malt pipe is please. Is it the grain basket?

Thanks

Mike

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

^^ I don't own one yet either, but yes that is basically a grain/malt basket. I may pull the trigger tomorrow.

TheCanisDirus

Well-Known Member

I've been away from home brewing for little while and was about to get rid of all my gas stuff and pick up a 10.5 today but they're sold out for this run^^ I don't own one yet either, but yes that is basically a grain/malt basket. I may pull the trigger tomorrow.

are they taking orders? Well it is a good sign that they sell out every time they make them.I've been away from home brewing for little while and was about to get rid of all my gas stuff and pick up a 10.5 today but they're sold out for this run

TheCanisDirus

Well-Known Member

Yeah the Blichmann/Anvil Foundry seems like the best all around sub $500 AIO by a good margin.are they taking orders? Well it is a good sign that they sell out every time they make them.

Pulled the trigger on a 6.5 Foundry with Pump. Should get it Mid-May. Stimulus, baby!

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

are they taking orders? Well it is a good sign that they sell out every time they make them.

Probably a WFH purchase but I couldn’t resist either. I bought from Great Fermentations because on the pre-sale they don’t charge until it ships, you can cancel the order until it ships.

Last edited:

dandksutton

Member

- Joined

- Apr 22, 2020

- Messages

- 5

- Reaction score

- 1

The extra $100 is for the circulation pump, hose, and flow control clamp.Looks great but why does the video advertise the price $100 less than the site?

I will wait for a few months of reviews but I may be interested in picking one of these up I like it better than the Robobrew, and at half the price of a Grainfather that's attractive, I wonder if you can step mash with it unattended?

Noob_Brewer

Well-Known Member

Looks like I might need to get a bag for the malt pipe if I want to do a finer crush to help efficiency. I also have never stirred the entire grain bed. I just rake the top 1/3 every 15 mins with the recirculating pump, so I may give this a shot as well.

What is your sparging technique with the foundry? Once my mash is over I have been bringing the temp up to 170 for a mash out. As soon as it hits 170 I pull the malt pipe up and lock it in. Then as the grains are draining I'll slowly pour my sparge water in. I have been leaving the perforated disc on the top as I pour to help allow it to trinkle in while sparging. Would there be a better sparging technique on this system that will yield better efficiency?

I think sparging is the most difficult part of this system in my humble opinion. Since Ive settled on a finer crush and using a wilser bag, this is how Ive been sparging: I mash out to 168 and then raise the malt-pipe and rest on the support ring. I wait until most wort has drained and then pour over the sparge water over the recirc disc. I then take out the recirc disc and "knife" the grain bed with my mash paddle which releases a good bit of wort. Then I take off the malt-pipe handle in order to lift the bag a couple of inches off the bottom of the malt-pipe and hold for a few seconds to let wort go to the bottom of the bag and then place it back down and again, can hear the wort leaving malt-pipe. I do this 2-3 times and lastly I gently push down on the bag to "squeeze" the last bit of wort out. I don't push too hard because the support ring can become a little unsteady AND I don't want to damage the bottom of the malt-pipe due to overpressure. All of this process has taken me about 30 minutes total. But Im still figuring out what my grain absorption rate should be in beer smith so that I don't have to "squeeze every last drop" out of the bag manually in order to hit my pre-boil volume. Not ideal setup but its been working for me and still tweaking but I am consistently getting ~76% mash/lauter efficiency this way.

SundayBrewer

Well-Known Member

What's the hose od size that comes with the pump. I would like to use my MKII pump and hoses already set up with camlocks.

Also what's the temp difference from the temp probe to the top of the mash. tks

Also what's the temp difference from the temp probe to the top of the mash. tks

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

120V &/or 240V

I'm going to re-plug for 240V but I know many want both 120V and 240V capabilities. I see the electric brewing guy on YouTube made an adapter so you don't need to cut the cord but it does not seem the way to go. I'm not an electrician so don't know how this works or how much cost it would add but I have s welder that runs on 120V and 240V. The welder cord has a threaded end with four conductors that fastens to either a 120V or 240V plug adapter. The welding machine auto-detects the line voltage.

I'm going to re-plug for 240V but I know many want both 120V and 240V capabilities. I see the electric brewing guy on YouTube made an adapter so you don't need to cut the cord but it does not seem the way to go. I'm not an electrician so don't know how this works or how much cost it would add but I have s welder that runs on 120V and 240V. The welder cord has a threaded end with four conductors that fastens to either a 120V or 240V plug adapter. The welding machine auto-detects the line voltage.

I think sparging is the most difficult part of this system in my humble opinion. Since Ive settled on a finer crush and using a wilser bag, this is how Ive been sparging: I mash out to 168 and then raise the malt-pipe and rest on the support ring. I wait until most wort has drained and then pour over the sparge water over the recirc disc. I then take out the recirc disc and "knife" the grain bed with my mash paddle which releases a good bit of wort. Then I take off the malt-pipe handle in order to lift the bag a couple of inches off the bottom of the malt-pipe and hold for a few seconds to let wort go to the bottom of the bag and then place it back down and again, can hear the wort leaving malt-pipe. I do this 2-3 times and lastly I gently push down on the bag to "squeeze" the last bit of wort out. I don't push too hard because the support ring can become a little unsteady AND I don't want to damage the bottom of the malt-pipe due to overpressure. All of this process has taken me about 30 minutes total. But Im still figuring out what my grain absorption rate should be in beer smith so that I don't have to "squeeze every last drop" out of the bag manually in order to hit my pre-boil volume. Not ideal setup but its been working for me and still tweaking but I am consistently getting ~76% mash/lauter efficiency this way.

Thank you for your input. Going to try and get a bag for my next batch and try this out along with a finer crush. I'd be super happy with 76 percent efficiency. Especially if I can consistently hit it. I'd like to be able to brew a 7-8% abv beer without having to max out the capacity of grains this thing can handle from getting low 50% efficiency lol

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

Thank you for your input. Going to try and get a bag for my next batch and try this out along with a finer crush. I'd be super happy with 76 percent efficiency. Especially if I can consistently hit it. I'd like to be able to brew a 7-8% abv beer without having to max out the capacity of grains this thing can handle from getting low 50% efficiency lol

Has anyone tried “malt conditioning” with finer crush? Might help liquid flow through grain bed and reduce chance of stuck sparge.

TheCanisDirus

Well-Known Member

How much boil-off does the 10.5 lose on 120 and 240? Trying to figure out what sort of ventilation i'm going to need switching to garage (or laundry room lol) small 5 gallon batch brewing.

I'm guessing a Steam Slayer would be overkill... but it looks like it could work with the stock lid. Hmmm, wonder if i could tap into the 4" dryer outlet pipe (as it exits the foundation with a new y-split. Could then make a little DIY fan and hood lol. Or I could just brew in the unheated garage but no way to vent there save for opening the garage door.

I'm guessing a Steam Slayer would be overkill... but it looks like it could work with the stock lid. Hmmm, wonder if i could tap into the 4" dryer outlet pipe (as it exits the foundation with a new y-split. Could then make a little DIY fan and hood lol. Or I could just brew in the unheated garage but no way to vent there save for opening the garage door.

What size hole is the handle opening?

@highland_brewer told me the 110 wasn’t bad with no ventilation.

I’m thinking 220 shouldn’t be bad either if adjusting the boil down to a gentle boil.

I’m ordering the 10.5 tomorrow if all goes well.

@highland_brewer told me the 110 wasn’t bad with no ventilation.

I’m thinking 220 shouldn’t be bad either if adjusting the boil down to a gentle boil.

I’m ordering the 10.5 tomorrow if all goes well.

How much boil-off does the 10.5 lose on 120 and 240? Trying to figure out what sort of ventilation i'm going to need switching to garage (or laundry room lol) small 5 gallon batch brewing.

I'm guessing a Steam Slayer would be overkill... but it looks like it could work with the stock lid. Hmmm, wonder if i could tap into the 4" dryer outlet pipe (as it exits the foundation with a new y-split. Could then make a little DIY fan and hood lol. Or I could just brew in the unheated garage but no way to vent there save for opening the garage door.

If you're doing it in a laundry room you are going to need some kind of ventilation. I did a batch in my kitchen and the windows of my downstairs steamed up pretty good. I ended up opening the windows to help with moisture. I think I boiled off about .6 gallons per hour on 120v from calculation. When I brewed in my kitchen I did a 90 minute boil, so I was closer to a gallon boiled off. I'd like to run it on 240v, but the only 240v I have is in my laundry room. I'm assuming it is the same for your household, because you mentioned brewing in the laundry room.

I've since moved back to the garage with the foundry. Mainly because of the mess I create in the kitchen and easier clean up with the hose vs. a kitchen sink. Towels everywhere to collect wort and water on the floor from disconnecting the pump and other random things spilling when pulling out the malt pipe. Just easier for me to stay in the garage, but it is nice to have the option for indoors if needed.

Noob_Brewer

Well-Known Member

Thank you for your input. Going to try and get a bag for my next batch and try this out along with a finer crush. I'd be super happy with 76 percent efficiency. Especially if I can consistently hit it. I'd like to be able to brew a 7-8% abv beer without having to max out the capacity of grains this thing can handle from getting low 50% efficiency lol

You can certainly do 7-8% ABV beers with this system. Just took a hydrometer sample of my first Double NEIPA today that is now 8.0%. I did use 0.5lb of dextrose in the boil to help achieve this. The total grains in the mash was 18.25lbs which was comprised of 0.75lb of rice hulls, 11.5lb golden promise, 3.75lb flaked oats, 1.75lb white wheat, and 0.5lb of honey malt. I lowered the water to grist ratio a little to let it all fit and it was fairly thick but in the end my mash/lauter efficiency was 74.8% and thats with a pretty sticky grain bill with about ~30% oats/wheat. So Im happy with that. Before I added the dextrose to the boil, I took a refractometer reading and was on track to get an OG of 1.071 without the dextrose. With it, I ended my OG at 1.075. So even without dextrose, you can easily get OGs in the 1.065-1.071ish range when mash/lauter efficiency is around 75-76%. Cheers!

Noob_Brewer

Well-Known Member

How much boil-off does the 10.5 lose on 120 and 240? Trying to figure out what sort of ventilation i'm going to need switching to garage (or laundry room lol) small 5 gallon batch brewing.

I'm guessing a Steam Slayer would be overkill... but it looks like it could work with the stock lid. Hmmm, wonder if i could tap into the 4" dryer outlet pipe (as it exits the foundation with a new y-split. Could then make a little DIY fan and hood lol. Or I could just brew in the unheated garage but no way to vent there save for opening the garage door.

my boil off rate is 1gallon per hour on 240V. I tested this with water twice. I brew in my garage as I prefer to spread out all my brew stuff and keep any messes/clutter outside the kitchen. My foundry is close to the end/opening of the garage too so most all the steam simply goes outside.

Noob_Brewer

Well-Known Member

Has anyone tried “malt conditioning” with finer crush? Might help liquid flow through grain bed and reduce chance of stuck sparge.

I have not done this but have considered it. Im crushing at 0.030" and not conditioning. I don't start the recirc pump until about 20-25minutes after mashing in and when I start it, it really is a slow pace. While I haven't measured the flow I use, I know its pretty dang slow but recirculating definitely helps with temp stratification in this system IMO. I do 90 minute mashes although most of the conversion occurs before the 40minute mark based on my refractometer readings. I haven't had a stuck mash yet at this mill gap setting, but I use a wilser bag. The reason why I state this is because on my second brew (Ive now done 12 on this system), I crushed at 0.036" but recirculated a little fast and didn't stir the grain enough and instead of getting wort flowing out the top of the malt-pipe, because I used a bag, Im 99.9% sure the wort flowed between the malt pipe and bag where there is no grain. So Im pretty sure I had a "stuck mash" but the wort could still flow between the malt-pipe and bag where there was no grains ie. no resistance to flow. That brew, my mash efficiency was 58% lol. Live and learn!

Last comment: even when not hitting my numbers, the beers Ive brewed on this system have still been good-->great. My judge is my wife and thats all that matters lol.

TheCanisDirus

Well-Known Member

If you're doing it in a laundry room you are going to need some kind of ventilation. I did a batch in my kitchen and the windows of my downstairs steamed up pretty good. I ended up opening the windows to help with moisture. I think I boiled off about .6 gallons per hour on 120v from calculation. When I brewed in my kitchen I did a 90 minute boil, so I was closer to a gallon boiled off. I'd like to run it on 240v, but the only 240v I have is in my laundry room. I'm assuming it is the same for your household, because you mentioned brewing in the laundry room.

I've since moved back to the garage with the foundry. Mainly because of the mess I create in the kitchen and easier clean up with the hose vs. a kitchen sink. Towels everywhere to collect wort and water on the floor from disconnecting the pump and other random things spilling when pulling out the malt pipe. Just easier for me to stay in the garage, but it is nice to have the option for indoors if needed.

Exactly this. The only 240v i have is an extra one in the laundry room. The room is directly behind the garage so i could theoretically take that 240v from the box with a new longer wire and throw it over the wall (joist ceilings in laundry room) quite easily. (Id grab a 30A GFCI of course) Or i just run it old 120v.

Maybe i'll just have to brew in the garage with the garage door up or half-way and have a fan blow everything towards that end.

The wife and I don't drink too much beer but all the hops i planted 4 years ago are now coming in crazy strong so i figure they must be utilized lol! I haven't touched any of my propane gear in maybe 4 years and these new inexpensive AIO electric systems seem like a god send for brewers like me.

harrower

Active Member

What size hole is the handle opening?

@highland_brewer told me the 110 wasn’t bad with no ventilation.

I’m thinking 220 shouldn’t be bad either if adjusting the boil down to a gentle boil.

I’m ordering the 10.5 tomorrow if all goes well.

You can boil on 220 and just adjust power to a lower setting.

Be aware that 240v extension cord is insanely expensive. If I remember right, my friend paid $300 for 20-25 feet.Exactly this. The only 240v i have is an extra one in the laundry room. The room is directly behind the garage so i could theoretically take that 240v from the box with a new longer wire and throw it over the wall (joist ceilings in laundry room) quite easily. (Id grab a 30A GFCI of course) Or i just run it old 120v.

Maybe i'll just have to brew in the garage with the garage door up or half-way and have a fan blow everything towards that end.

The wife and I don't drink too much beer but all the hops i planted 4 years ago are now coming in crazy strong so i figure they must be utilized lol! I haven't touched any of my propane gear in maybe 4 years and these new inexpensive AIO electric systems seem like a god send for brewers like me.

TheCanisDirus

Well-Known Member

I meant I could just run a new wire to the main box since it's on the other side of my garage wall and is exposed joist ceiling. I could then drop it down the other side of the wall to the garage which has a cement and fiber board (i think it's weird) ceiling and install and outlet (and 30A GFCI fuse in box).Be aware that 240v extension cord is insanely expensive. If I remember right, my friend paid $300 for 20-25 feet.

Or maybe i just say screw it and use 120 and it just takes a little longer and is not as vigorous. In my 15 years of home brewing i've always been a low-roll boiler.

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

Be aware that 240v extension cord is insanely expensive. If I remember right, my friend paid $300 for 20-25 feet.

I paid just over $100 for a 50 ft 8/3 welding extension (monogramed) with lighted ends. I'm not an electrician but from reference tables 12/3 is rated 240/20 and 10/3 for 240/30.

rac3850

Member

Be aware that 240v extension cord is insanely expensive. If I remember right, my friend paid $300 for 20-25 feet.

My Anvil 10.5 manual 's 240 volt wiring guide specifies a minimum 15 amp 240 volt grounded plug. That should mean that the minimum wire gauge should be 14 (14-3 wire). I wouldn't run much over 10 feet with this gauge though. I'd recommend 12-3 flexibile wire (which is 4 conductor), which can handle up to 20 amps (max 4800 watts), and up to 20 or so feet should be no problem. Homedepot carries 12-3 flexible cord for $1.00/foot +/-. So a 20 foot cord can be made up for about $20 to $25 in wire plus the selected connectors on the ends.

An alternative is Harborfreight's Predator 25 ft. 10 gauge generator cord (https://www.harborfreight.com/25-ft-x-10-gauge-generator-duty-twist-lock-extension-cord-62308.html) for $50. This is overkill as far as amperage capacity, but is very reasonable considering it already has connectors at both ends (NEMA L 14-30 twist lock plugs). However, if you don't have a min. 30 amp circuit I doubt you would want to use these connectors.

The real killer is that the circuit should be ground fault protected. Dryer circuits aren't necessarily ground fault protected. A 20 amp 240 volt in-box ground fault circuit breaker could set you back close to $100 just to buy it (easy to put in but I understand many may be reluctant). The alternative is an in-line ground fault breaker which runs about $60 to $70. I have the in-line breaker in my extension cord, got lucky and bought it used off ebay and it works great.

So it shouldn't be $300, even with an inline ground fault, but it still ain't cheap. Remember, if you are running on 120v you will be maxing out the load on a standard 15 amp circuit, so you won't be able to run another major load on that same 15 amp circuit (think induction heater or electric coil burner, or the 5-6 amp start load on that handy kegerator). I had access to one 20 amp 120v circuit and an existing 20 amp 240 v circuit, so it was a no brainer for me to go 240v. Then I had plenty of headroom on the 120v circuit for my induction plate, mini-fridge, pump and electric kettle for sparge water.

He probably over-paid. He's not an electrician either so it's likely he bought thicker cable than he needed too. It was about 3-4 years ago when he built his all-electric system and was complaining that the dumb extension cord cost him more than anything else.So it shouldn't be $300, even with an inline ground fault, but it still ain't cheap.

- Joined

- Feb 26, 2013

- Messages

- 207

- Reaction score

- 86

I changed mine to the 240 plug but was able to find an adapter like this. I don't know if they are available for every 240 plug configuration. I tried it out with the adapter at 120 and it worked fine. The only thing I was cautioned on is if I use 120, make sure when I go back to 240 be sure to switch the Foundry back to 240. 120 on the Foundry to a 240 outlet equals fried foundry. I have a 240 in my brew shed, so will rarely use the adapter but wanted the option to take the Foundry where 240 is not available. I am no electrician, so if anyone sees a problem with this, let me know120V &/or 240V

I'm going to re-plug for 240V but I know many want both 120V and 240V capabilities. I see the electric brewing guy on YouTube made an adapter so you don't need to cut the cord but it does not seem the way to go. I'm not an electrician so don't know how this works or how much cost it would add but I have s welder that runs on 120V and 240V. The welder cord has a threaded end with four conductors that fastens to either a 120V or 240V plug adapter. The welding machine auto-detects the line voltage.

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

I changed mine to the 240 plug but was able to find an adapter like this. I don't know if they are available for every 240 plug configuration. I tried it out with the adapter at 120 and it worked fine. The only thing I was cautioned on is if I use 120, make sure when I go back to 240 be sure to switch the Foundry back to 240. 120 on the Foundry to a 240 outlet equals fried foundry. I have a 240 in my brew shed, so will rarely use the adapter but wanted the option to take the Foundry where 240 is not available. I am no electrician, so if anyone sees a problem with this, let me knowView attachment 677239

@szap

Nice do you have a link for the adapter?

Edit - found one on Amazon that is the reverse sex on both ends so looks like that would work too if you leave the 120v plug on the Foundry. But like all have warned must be very careful!

Thanks

Mike

Last edited:

Noob_Brewer

Well-Known Member

I bought a 20amp/250V extension cable 12AWG 25 foot cord from amazon - it is UL certified too. Its worked great.

https://www.amazon.com/gp/product/B0818WCWJH/

I paid ~$45 I think.

https://www.amazon.com/gp/product/B0818WCWJH/

I paid ~$45 I think.

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

I bought a 20amp/250V extension cable 12AWG 25 foot cord from amazon - it is UL certified too. Its worked great.

https://www.amazon.com/gp/product/B0818WCWJH/

I paid ~$45 I think.

This is what I found:

https://www.amazon.com/gp/product/B075FTC9RT/ref=ox_sc_act_title_1?smid=A1KTKW39RZBQC6&psc=1

Looks like if I plug the 120V Foundry male plug into it I'm set for 220V (after I put a #6-30 receptacle on my 240V GFCI source).

Thanks for the help.

(looks like that cord you bought is not available any more)

Check out this thread for ventilation:How much boil-off does the 10.5 lose on 120 and 240? Trying to figure out what sort of ventilation i'm going to need switching to garage (or laundry room lol) small 5 gallon batch brewing.

I'm guessing a Steam Slayer would be overkill... but it looks like it could work with the stock lid. Hmmm, wonder if i could tap into the 4" dryer outlet pipe (as it exits the foundation with a new y-split. Could then make a little DIY fan and hood lol. Or I could just brew in the unheated garage but no way to vent there save for opening the garage door.

https://www.homebrewtalk.com/forum/...ainless-vent-hood.418665/page-10#post-8785551

Brewed my third beer in the Foundry today. Used rice hulls in the first two. Today, used a bag, no rice hulls. If I did my math correctly, 66% efficiency on batch 2, and 88% today with the bag. First two had a lot of sediment, hardly any today.

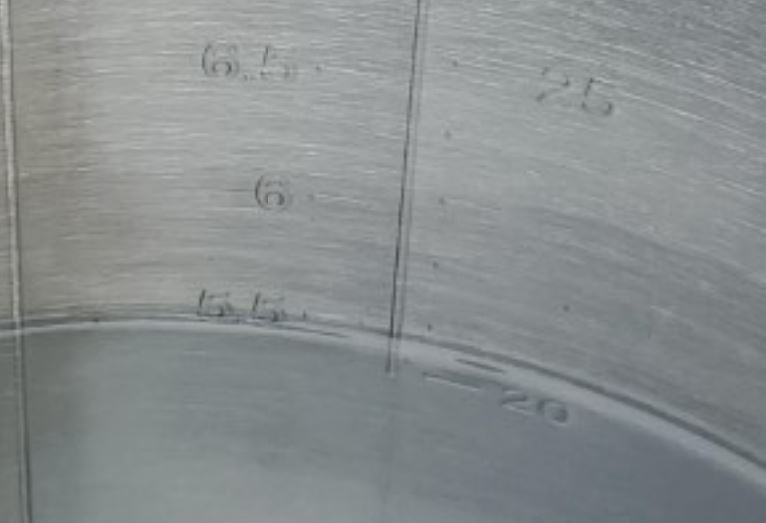

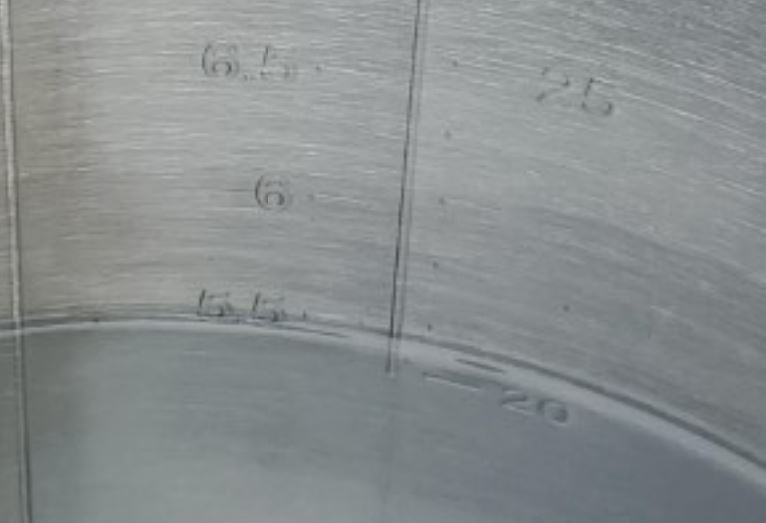

Also today, measured out six gallons of water, poured it in the kettle, realized measurements are off:

Also today, measured out six gallons of water, poured it in the kettle, realized measurements are off:

TheCanisDirus

Well-Known Member

Did you measure the water you filled it up with by weight or volume? If volume try weight next time. Curious to see the results.Brewed my third beer in the Foundry today. Used rice hulls in the first two. Today, used a bag, no rice hulls. If I did my math correctly, 66% efficiency on batch 2, and 88% today with the bag. First two had a lot of sediment, hardly any today.

Also today, measured out six gallons of water, poured it in the kettle, realized measurements are off:View attachment 677296

- Joined

- Jan 17, 2017

- Messages

- 302

- Reaction score

- 131

Brewed my third beer in the Foundry today. Used rice hulls in the first two. Today, used a bag, no rice hulls. If I did my math correctly, 66% efficiency on batch 2, and 88% today with the bag. First two had a lot of sediment, hardly any today.

Also today, measured out six gallons of water, poured it in the kettle, realized measurements are off:View attachment 677296

What bag did you use? What crush did you use? (Interested in the water level markings mystery too)

Thanks

Similar threads

- Replies

- 12

- Views

- 769

- Replies

- 14

- Views

- 1K

- Replies

- 27

- Views

- 3K

- Replies

- 4

- Views

- 1K