capt_yo55arian

Well-Known Member

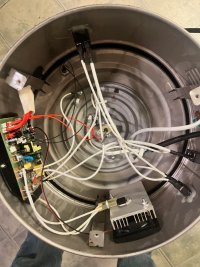

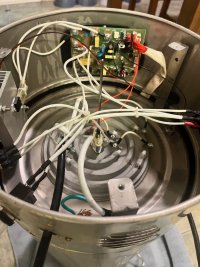

Right to the point- 10.5 Foundry from 2020, dozens of brews (latest one last month) with no issues. Hooked up to 240v. This week tried brewing, took couple hours to get to 100ish temp and I was like NOPE. It turns on, but heats incredibly slow (element issue?).

Tested the outlet no problem, looked at cable wiring for Anvil, seemed fine. I sent Blichmann an email and haven't heard back yet (weekend so no issue) but was wondering if anyone has experienced this.

Its got 8 gallons of water sitting in it and Im reluctant to drain until hear back from customer support, but, man... I've dialed this in just how I like it with BIAB and quick disconnects, I really don't want to give up on it.

Tested the outlet no problem, looked at cable wiring for Anvil, seemed fine. I sent Blichmann an email and haven't heard back yet (weekend so no issue) but was wondering if anyone has experienced this.

Its got 8 gallons of water sitting in it and Im reluctant to drain until hear back from customer support, but, man... I've dialed this in just how I like it with BIAB and quick disconnects, I really don't want to give up on it.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)