apache_brew

Well-Known Member

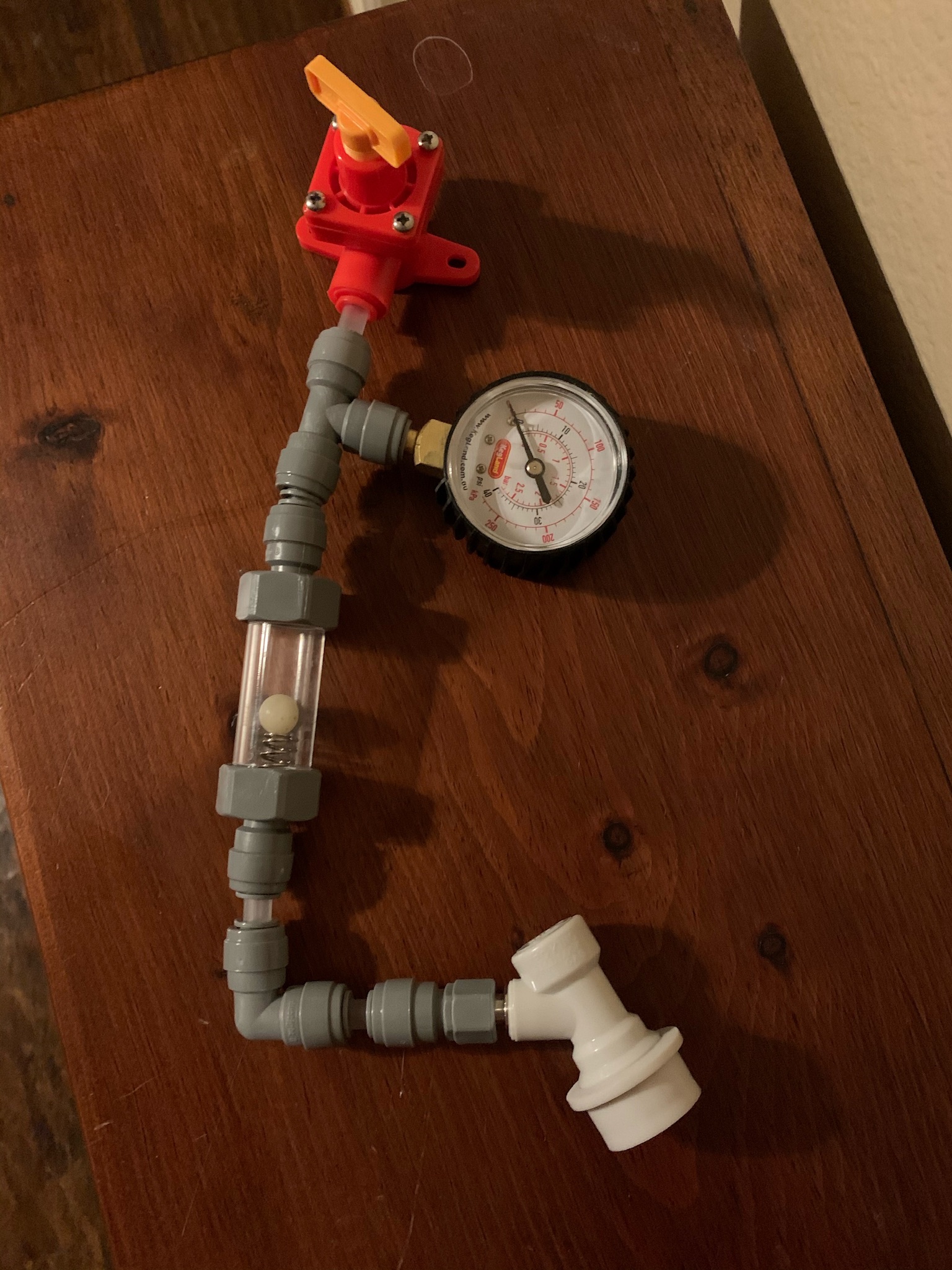

I found something like this configuration searching through google and decided to try it out given I had most of the parts laying around. I’m hoping the floating dip tube works out, I’ve never used one. The approach is to use the gas out post as the airlock/prv. Use the sightglass as a hop chamber that can be co2 purged with the ball lock posts. And use the butterfly valve to dump dry hops to minimize oxygen intrusion. After cold crash, transfer beer into kegs under pressure.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)