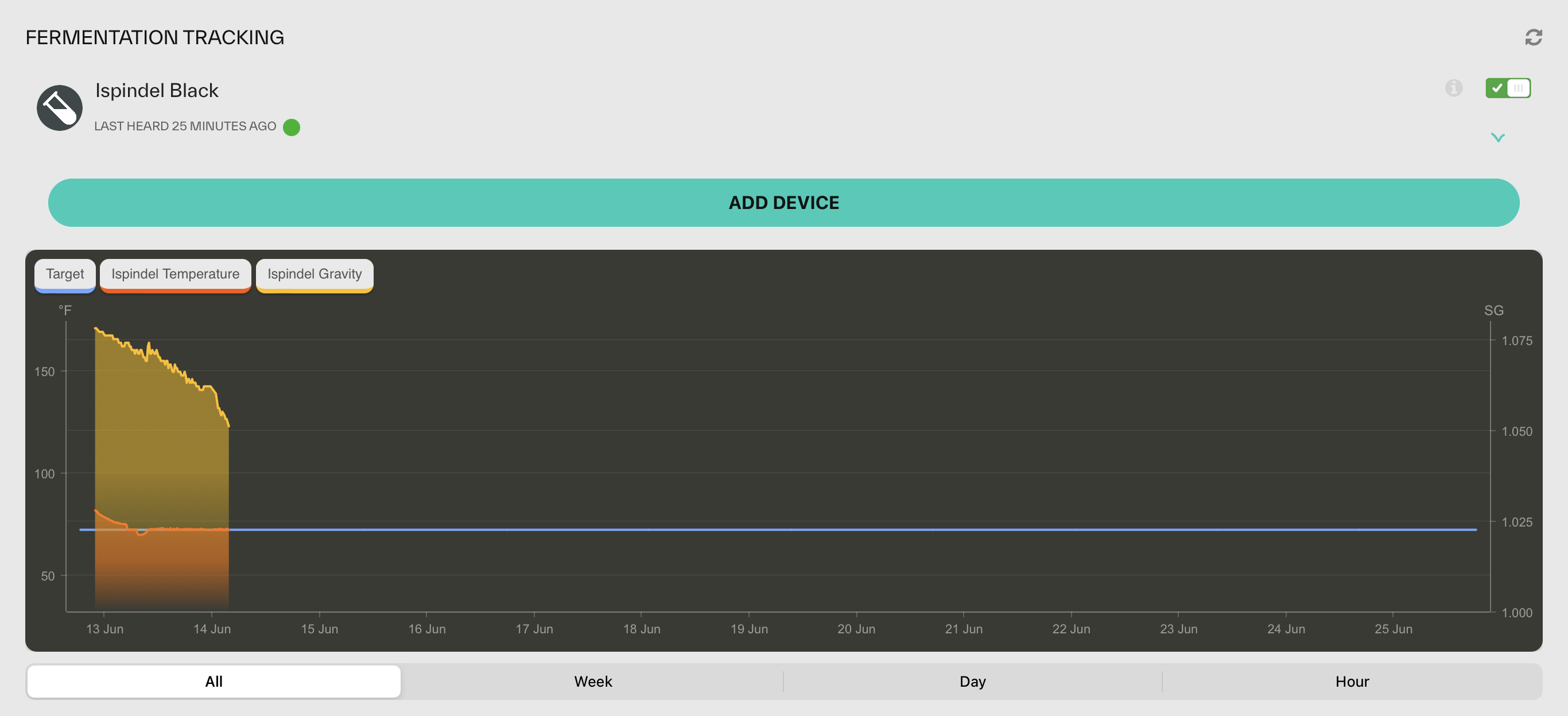

I know as a noobie, I‘m supposed to stick to simple, straight forward brews until I “get the hang of it“. Unfortunately, I’ve never been able to go with the ”status quo”.

Given my resilience to conform, I’ve been contemplating/planning a brown ale with a bit of uniqueness to it. I had an open fermenter and very little (I mean I made some) free time over the weekend, so what the hell… brew day!

This was definitely my most involved brew to date, which I know pales in comparison to some, but it was a good 6 hours start to finish that had several learning experiences along the way. Enough talk.. on to the pics (yes, I’m more of a visual person).

Dishes are done.. time to get dirty!

Given my resilience to conform, I’ve been contemplating/planning a brown ale with a bit of uniqueness to it. I had an open fermenter and very little (I mean I made some) free time over the weekend, so what the hell… brew day!

This was definitely my most involved brew to date, which I know pales in comparison to some, but it was a good 6 hours start to finish that had several learning experiences along the way. Enough talk.. on to the pics (yes, I’m more of a visual person).

Dishes are done.. time to get dirty!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)