Back to the original question.

Most home brewers go through same developmental process of DME starter kits to their ultimate setup. Along the way a lot of money is wasted on equipment that is eventually discarded as it's replaced with equipment we feel brews beer easier and better.

The questions to ask yourself are:

1. How much beer will I need and how often do I want to brew? This will determine system size.

2. How much money can I spent without serious harmonious disturbance at home? Think big.

3. Have I considered all brewing options? BTW a brew bag in the mash tun is a no brainer.

4. Am I a tinker or a buy a complete system type of guy? Important if you plan to design and build your own.

5. Am I making the best beer with the least amount of effort? Kegs vs bottles, electric vs propane, home RO system and salts vs tap or purchased water, pump vs all that lifting and pouring, scientifically documented and reproducible vs Saturday afternoon kicked back fun, et al.

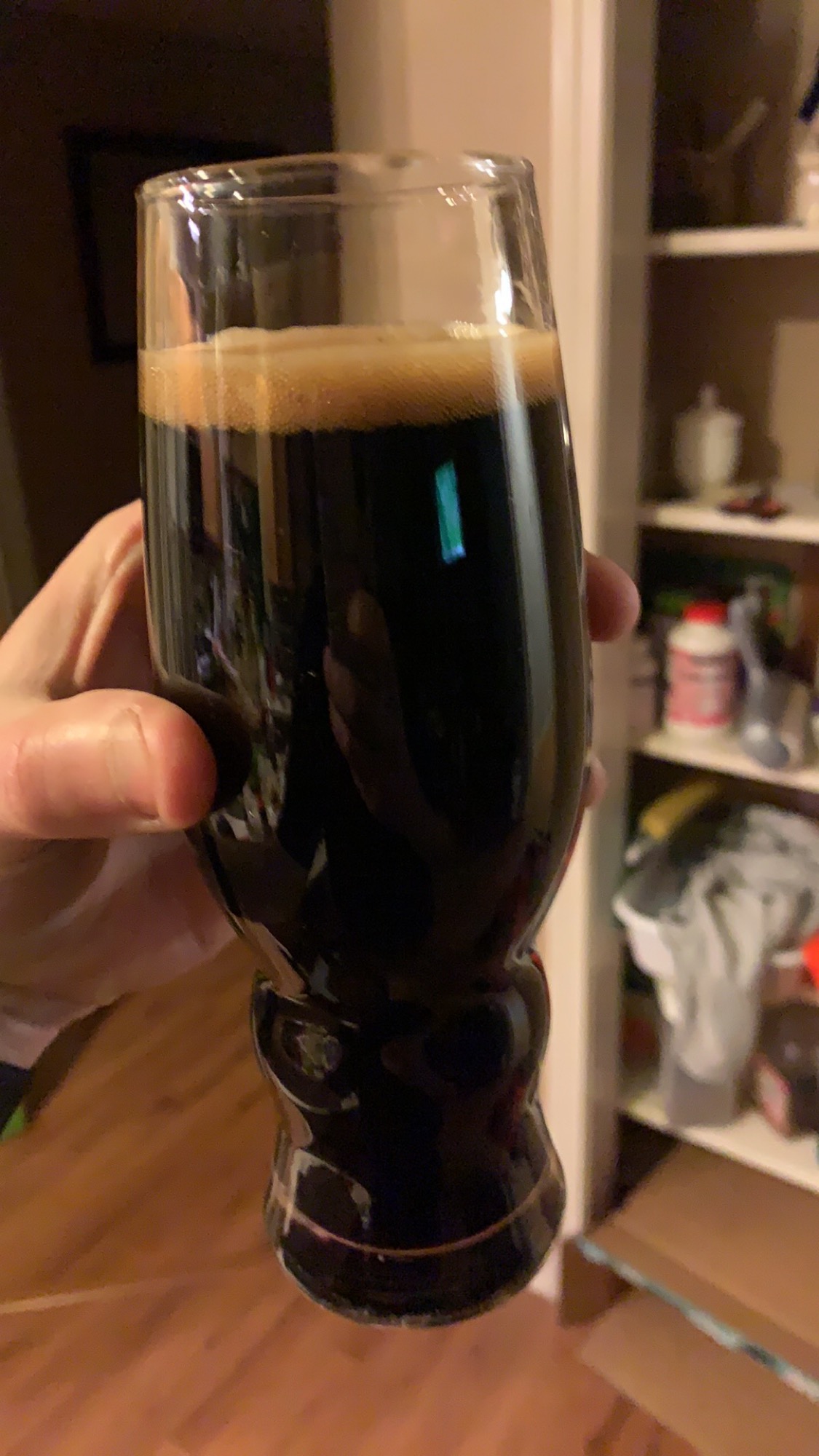

This is me 10 years later (pic).....I keg, use clean in place methods, use software to document everything, and still have that Saturday afternoon fun thing. I love brewing and can tinker with the best.

Crush grains directly to 30 gal mash tun with brew bag, 30 gallon RO water barrel (not shown), RIMS from brewhardware.com, Riptide pump, flowmeter, tipping kettle tables, Kelco CFC (I owned a Therminator, but clogs and very hard to clean), SCR two elements (240v and 120v), wireless temperature probes and 20 gal boil kettle. I make 11 gallon batches i.e. 2 x 5 gallon kegs worth monthly.

BTW nothing is simpler or faster than a single run 90 minute mash.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)