tipicreeper

Well-Known Member

Sanitary fittings are used mainly in the consumable liquids and biopharmaceutical industries.

Being that I am a custom machinery builder for the bio-pharm industry, I will attempt to convey what I know about sanitary piping for those who may not know their full use.

From a quick disconnect view, this type of piping is very effective and easy to use. If one is attempting to keep a sanitary system like in a food processing or pharmaceutical application there are other things to consider.

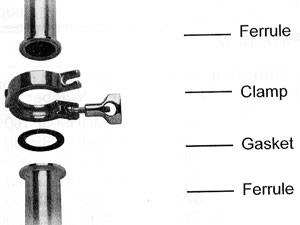

The whole idea of sanitary piping is to reduce bio-burden in the fluid path. The piping is sized by the outside diameter of tubing used in the fittings and the clamping flanges are common to certain multiple sizes. The key difference in keeping a sanitary system is in the gaskets between the clamping points. There are also great considerations to the surface finish of the fittings fluid path. The ASME BPE standard is an internal polish of at least 32 Ra. In essence, no stepped transitions or scratches where bugs can grow.

For instance, a ½ sanitary fitting has a ½ tubing OD and ¾ has a ¾ OD. Both fittings use the same clamp & gasket profile but the ½ fitting has a .370 inside diameter and the ¾ has a .620 ID. To match the tubing IDs

The same goes for 1 and 1 ½ piping. They use the same clamps & gasket profile but the ID of the gaskets are different. So, it is important to choose the correct gasket for the application.

So, if one was to make a transition from 1 piping to 1 ½ piping a person could just connect the fittings choose a gasket and apply the clamp; but from a fluid path bio-burden perspective, it would be proper to have a 1 ½ to 1 reducer and the appropriate gaskets on each side.

From a pure sanitary situation once an NPT connection is made, a transition to a non-BPE tank, a barbed fitting, or atmosphere, the system is no longer technically a sanitary system. There are sanitary hoses, and fittings to create sanitary hoses. These can be quite expensive and can be made at home but are generally custom made using appropriate materials by high dollar companies.

Many vendors supply sanitary fittings. By far the one that is most largely recognized is McMaster-Carr.

McMaster-Carr

I have found some less expensive places but I have OEM accounts with these people so YMWV.

For 316 & 303 Stainless:

Casella Sales & Marketing (They also do custom welded manifolds)

Valves, Gemu Valves and Distributor, Diaphragm Valves, Sanitary Valves, Aseptic Valves, Valves and Fittings, Sample Valves, Bleed Valves, Gemu Diaphragm Valves, Sanitary Diaphragm Valves, Stainless Steel, Stainless Fittings, BPE Fittings, ASMI BPE Fi (Sales contact Ira Colby)

For Polypropylene (Max 180 deg F) & PDVF (Max 240 deg F), (They also do custom welded manifolds)

BioConnexx, Inc. - Home (Sales contact Art Quade)

I hope this doesnt come across as a soap box, I just thought to throw it out there, it may help with the greater understanding.

If anyone is interested send me a PM, I may be able to get better pricing from the above vendors and would be happy to play intermediary at no cost.

Cheers,

David

Being that I am a custom machinery builder for the bio-pharm industry, I will attempt to convey what I know about sanitary piping for those who may not know their full use.

From a quick disconnect view, this type of piping is very effective and easy to use. If one is attempting to keep a sanitary system like in a food processing or pharmaceutical application there are other things to consider.

The whole idea of sanitary piping is to reduce bio-burden in the fluid path. The piping is sized by the outside diameter of tubing used in the fittings and the clamping flanges are common to certain multiple sizes. The key difference in keeping a sanitary system is in the gaskets between the clamping points. There are also great considerations to the surface finish of the fittings fluid path. The ASME BPE standard is an internal polish of at least 32 Ra. In essence, no stepped transitions or scratches where bugs can grow.

For instance, a ½ sanitary fitting has a ½ tubing OD and ¾ has a ¾ OD. Both fittings use the same clamp & gasket profile but the ½ fitting has a .370 inside diameter and the ¾ has a .620 ID. To match the tubing IDs

The same goes for 1 and 1 ½ piping. They use the same clamps & gasket profile but the ID of the gaskets are different. So, it is important to choose the correct gasket for the application.

So, if one was to make a transition from 1 piping to 1 ½ piping a person could just connect the fittings choose a gasket and apply the clamp; but from a fluid path bio-burden perspective, it would be proper to have a 1 ½ to 1 reducer and the appropriate gaskets on each side.

From a pure sanitary situation once an NPT connection is made, a transition to a non-BPE tank, a barbed fitting, or atmosphere, the system is no longer technically a sanitary system. There are sanitary hoses, and fittings to create sanitary hoses. These can be quite expensive and can be made at home but are generally custom made using appropriate materials by high dollar companies.

Many vendors supply sanitary fittings. By far the one that is most largely recognized is McMaster-Carr.

McMaster-Carr

I have found some less expensive places but I have OEM accounts with these people so YMWV.

For 316 & 303 Stainless:

Casella Sales & Marketing (They also do custom welded manifolds)

Valves, Gemu Valves and Distributor, Diaphragm Valves, Sanitary Valves, Aseptic Valves, Valves and Fittings, Sample Valves, Bleed Valves, Gemu Diaphragm Valves, Sanitary Diaphragm Valves, Stainless Steel, Stainless Fittings, BPE Fittings, ASMI BPE Fi (Sales contact Ira Colby)

For Polypropylene (Max 180 deg F) & PDVF (Max 240 deg F), (They also do custom welded manifolds)

BioConnexx, Inc. - Home (Sales contact Art Quade)

I hope this doesnt come across as a soap box, I just thought to throw it out there, it may help with the greater understanding.

If anyone is interested send me a PM, I may be able to get better pricing from the above vendors and would be happy to play intermediary at no cost.

Cheers,

David

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)