PaulHilgeman

Well-Known Member

- Joined

- Mar 14, 2008

- Messages

- 270

- Reaction score

- 7

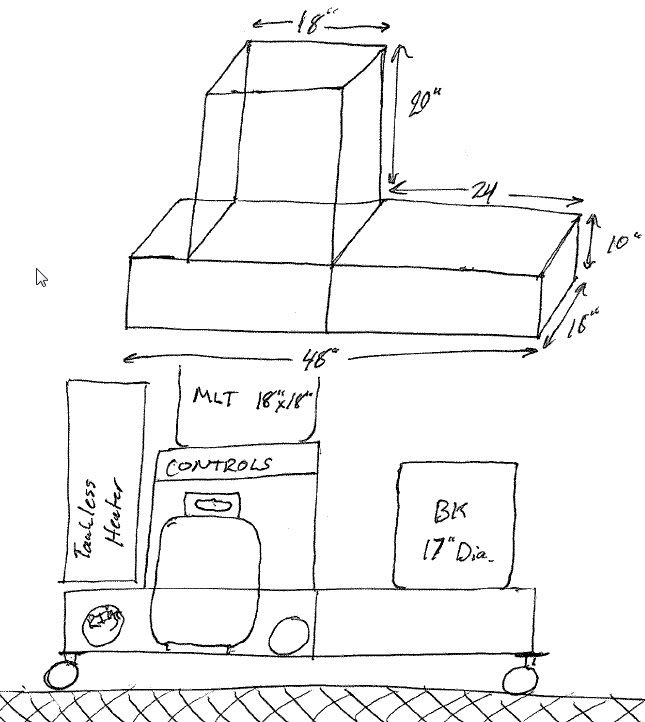

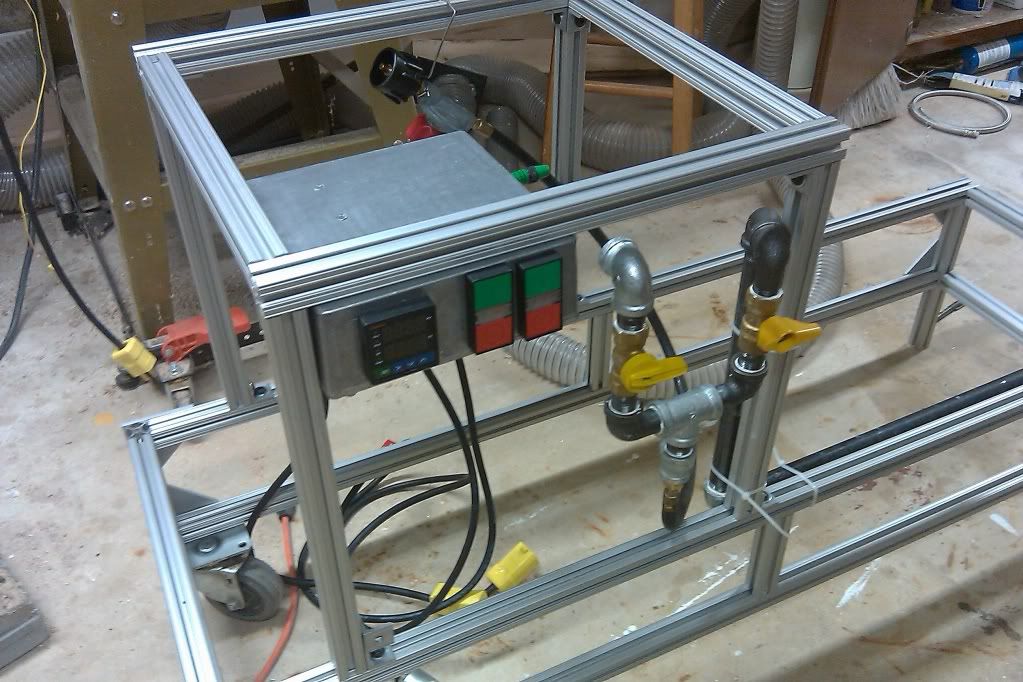

Anyone ever use 80/20 Aluminum Extrusions to build a brew stand? I would be doing a 10 gal 2-vessel system (Tankless HLT, MT and BK) just in a single tier.

Did you use the 1010, or the 1515 stuff? I know that this stuff is pretty strong, and my overall span would be shorter than most peoples, but I am unsure if the 1010 would be strong enough.

I'd love to see some pictures too.

Thanks.

Did you use the 1010, or the 1515 stuff? I know that this stuff is pretty strong, and my overall span would be shorter than most peoples, but I am unsure if the 1010 would be strong enough.

I'd love to see some pictures too.

Thanks.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)