This is very doable. Just give a little time to put together another diagram set for you.

What is your plan for the boil kettle?

What is your plan for the boil kettle?

This is very doable. Just give a little time to put together another diagram set for you.

What is your plan for the boil kettle?

Thanks P-J

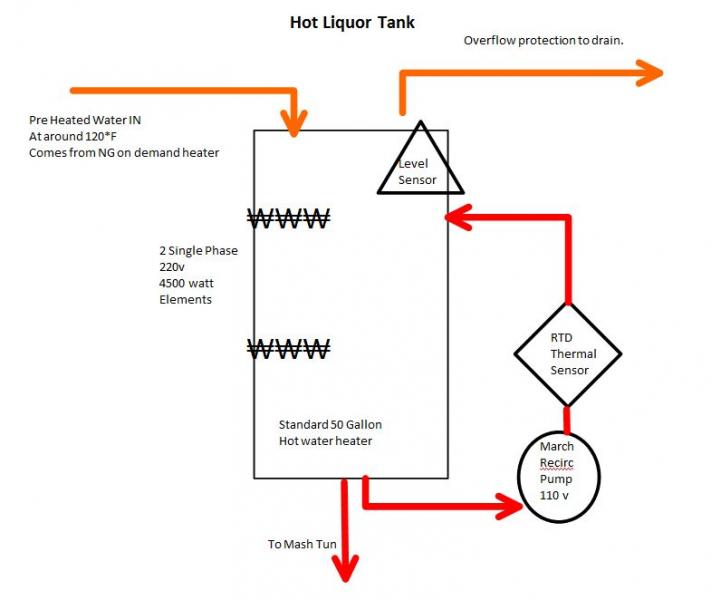

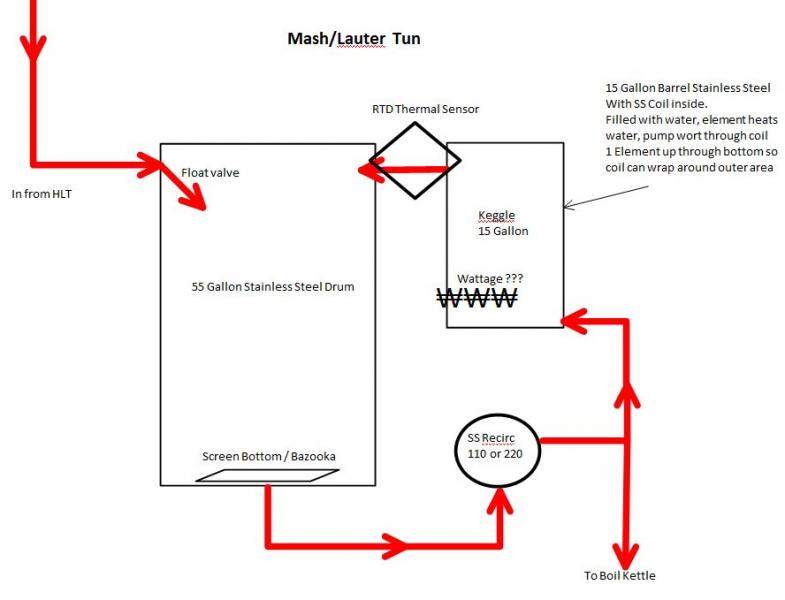

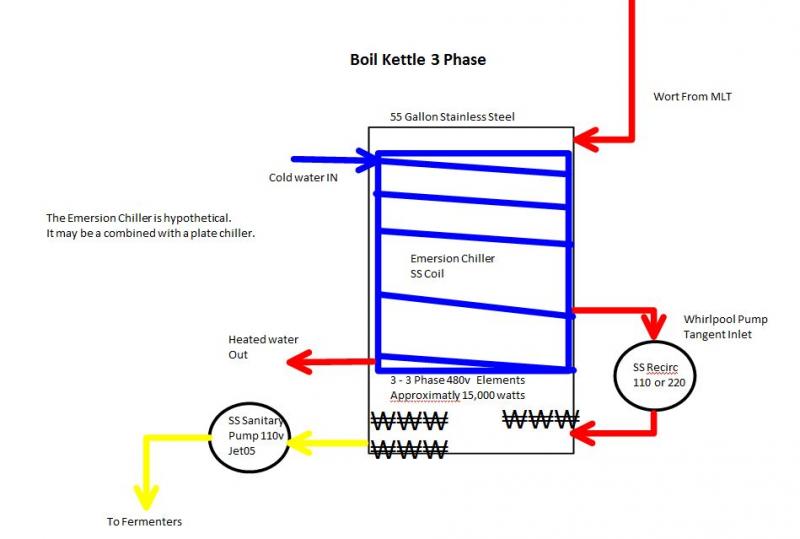

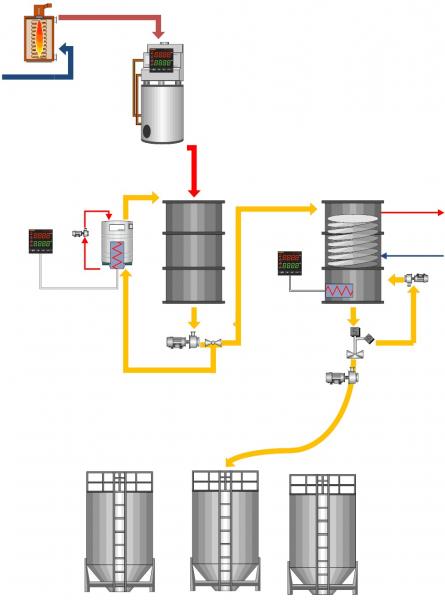

I'm getting the outline for the Mash Tun HERMS and the Boil Kettle. But they will all be independently controlled. That way if we change the system configuration we won't have controls tied together. I want to keep it modular.

I think right now I am wanting to do 3 220v single phase 4500 watt heating elements. Just seems simple, unless you think we have an advantage to putting 3 phase to it.

If you are intending to use 3 elements in any vessel, 3 phase will be less expensive both in the build and in the cost of power to run it.

Regarding the 3 phase you might have available. Is there any way tjhat you can determine what is actually available. If your power is 480V 3 phase the question becomes is that 480 power or 240/480 power or is it 277/480 power. I'm trying to determine how the 3 phase power is being delivered to your place, i.e is it by a Delta or "Y" transformer connections.

The other possibility is if you have 240V 3 phase available.

Single elements are certainly available for your use in the system. Check out this sites lists of high quality elements:

http://bostonheatingsupply.com/rheemelectricelements.aspx

I'll help you in any way that I can. I believe this to be a fun journey for me and it also keeps this old timer from becoming an alsheimer.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

this is insane!!!!

(in a good way)

but I'm doing this!

but I'm doing this!

I am still in the thought process of how that would work.You won't be able to clean your boil pot with you I'M chiller design,

Yes, stir motors already figured in on these.15.5gal Herms 50' 7/8 Copper or Stainle$$ coil will work, 2500w depends on volts I would use a stir motor on the HLTand HERMS,

YES, already have large supply.use 1 1/2 tri clover fitting everywhere

Several option for hooking up, went over it with my electrician. Easier to make the runs because less copper and conduit. And I have a panel close by the Brew Room that has extra room.To my under standing 3ph Elec is good for motors ie-3 phases, but on heaters a 3 ph system uses 3 elements 1 for each phase so only voltage is the advantage.

Good info, thanksOur 500gal. HLT is 240v 3PH and has 3 elements totaling 15KW

There are 4 5500w 220v elements in our 5bbl boil pot, 22KW using 94 amps

Yes agreed. Any suggestions on the Plate chiller.Spend money on Fermentors and a real Plate chiller and Glycol sys. and more

I got fever, and the only cure is some pictures of your equipment!

I'm looking to you (among others) when it comes to opening my commercial brewery. Just sayin...

Here is the Crusher/Mill I am ordering soon.

http://www.barleycrusher.com/barleycrushermicro.php

I have a piece of equipment off of our bone pile we have stripped down to mount it on.

Anyone know anything about these?

Nice to see the pictures of your progress. Best of luck