digitalpeer

Member

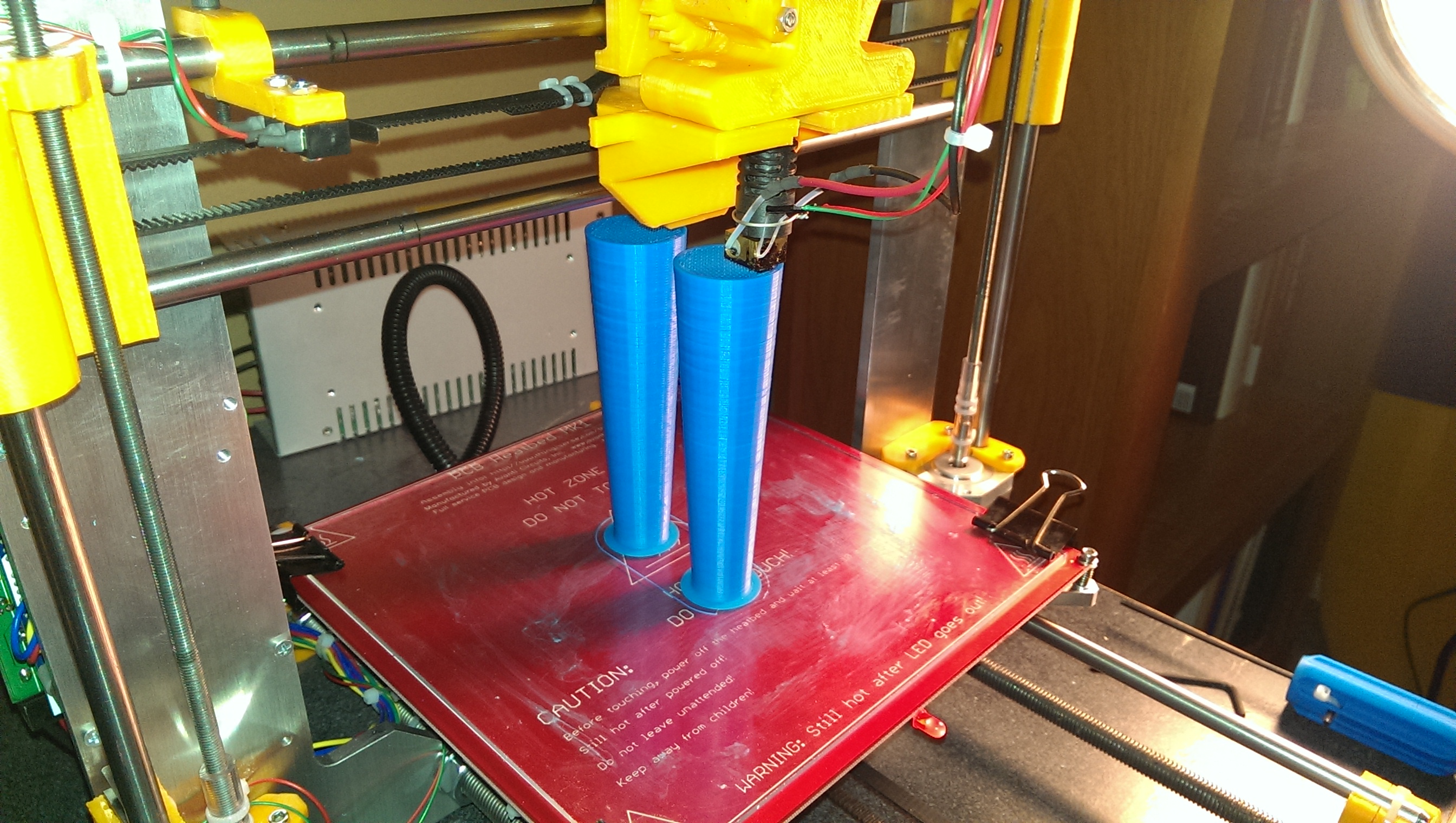

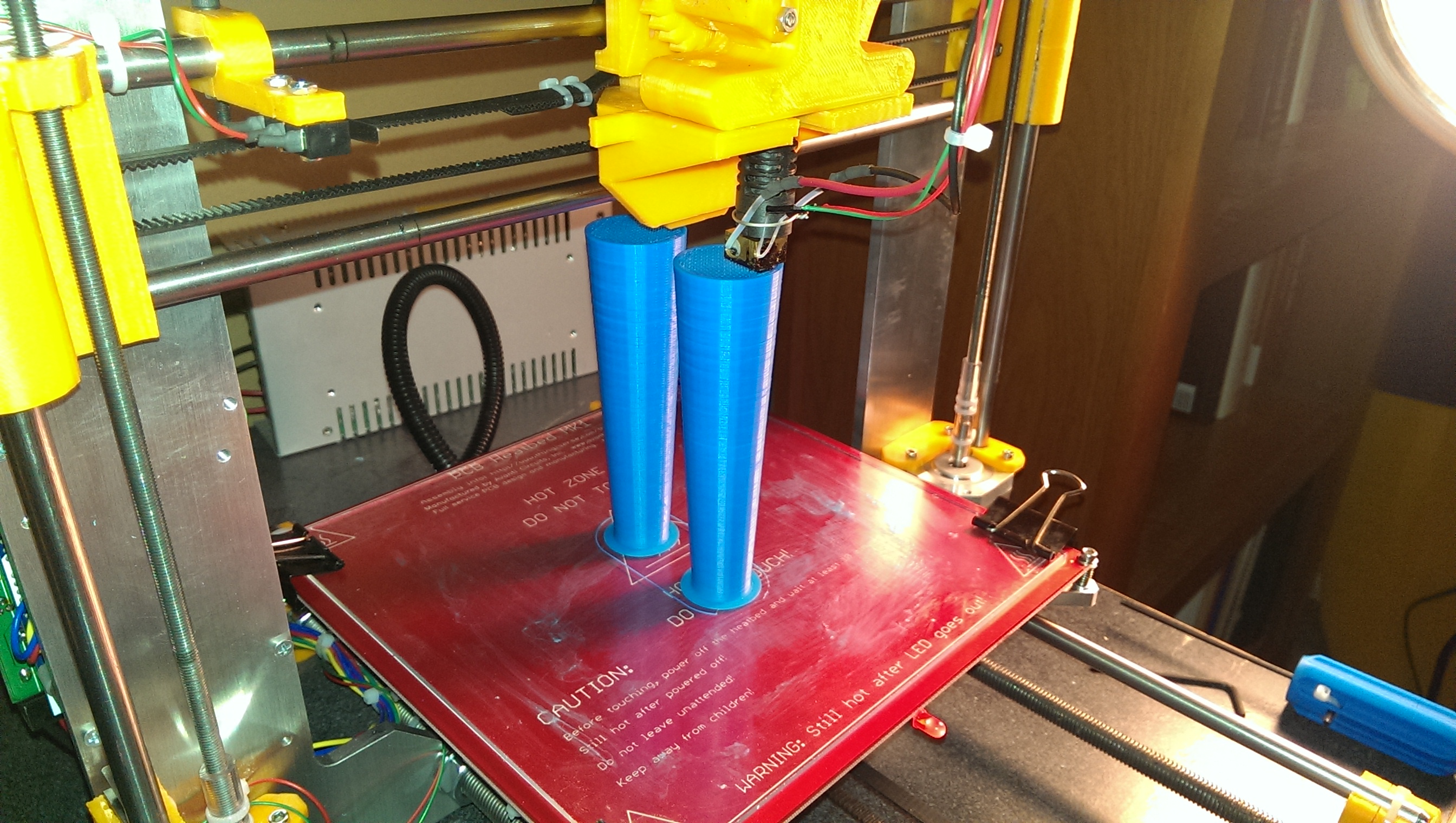

Here's one of my first stabs at modeling something for 3d printing. It doesn't get any simpler than a simple tap handle design. I used FreeCad and printed on a i3 Prusa printer.

More pictures and CAD/STL files can be found here.

In the middle of an 8 hour print, 2 at a time.

3 tap handles mounted.

More pictures and CAD/STL files can be found here.

In the middle of an 8 hour print, 2 at a time.

3 tap handles mounted.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)