Small update -

Since the last update I got the following items in:

Chugger center inlet pump

HERMS Coil

Mash Tun Dip Tube

Misc Stainless Hardware

Motorized Ball Valves

30 Plate Duda Chiller

Yesterday I mocked up my valve manifold, trying out a few different ways to put it all together, and make it easy to take apart.

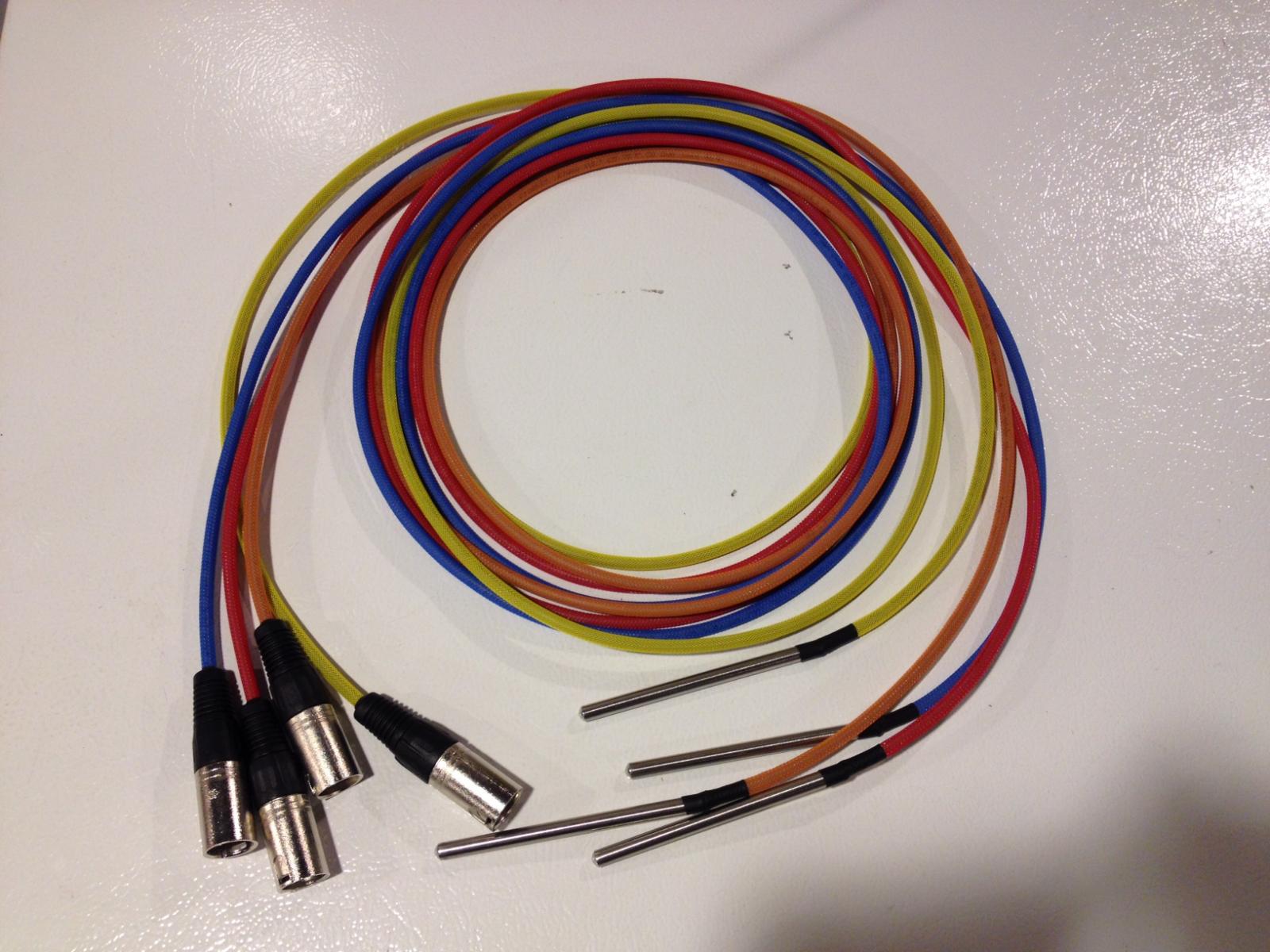

I installed XLR connectors on each of the valves.

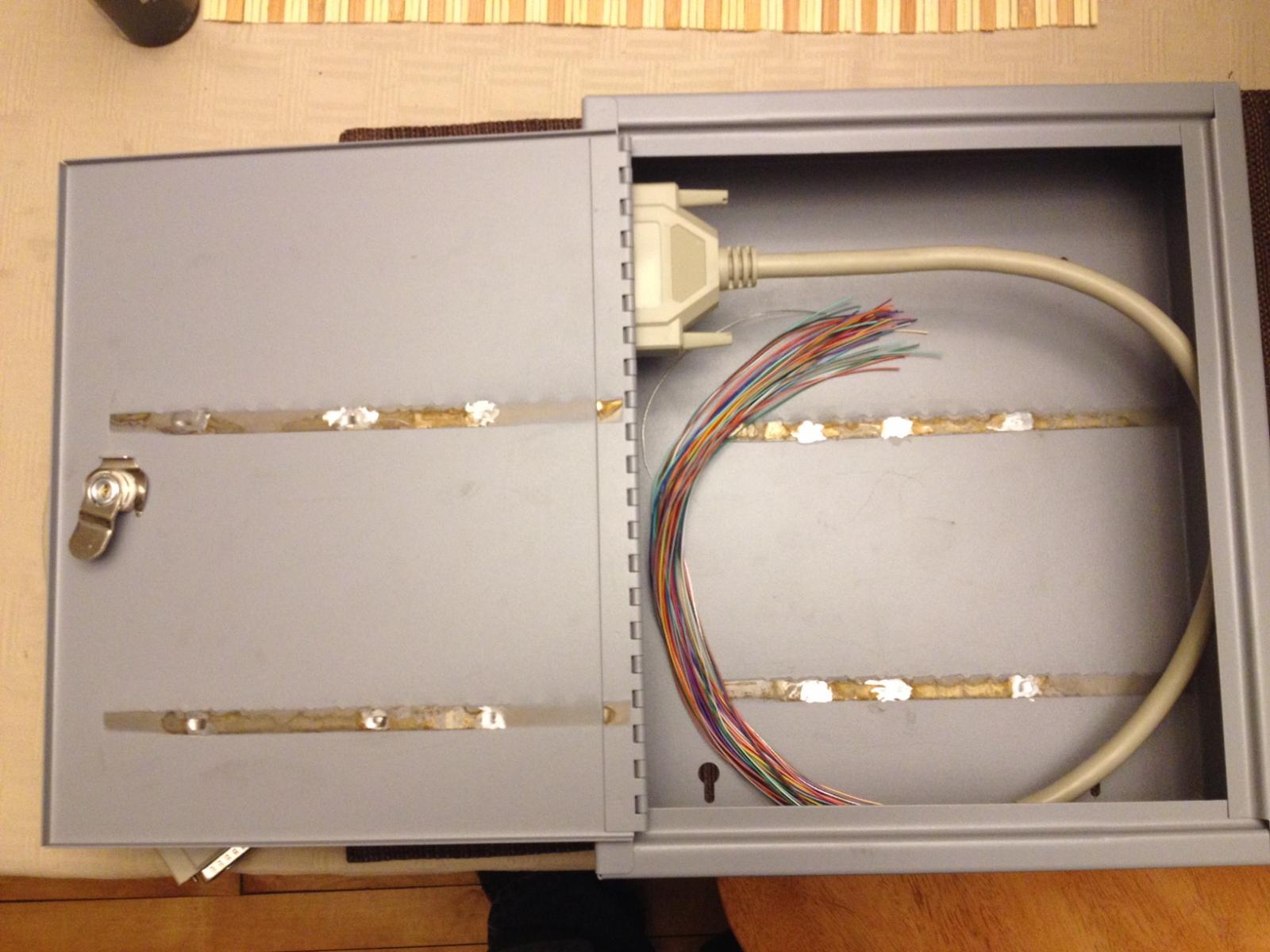

I pulled out the key tag holders from the key box. There were 3 spot welds that I had to grind out to remove the chunks of metal. I used JB weld to clean up rough areas and to fill in the mounting holes on the panel (not shown).

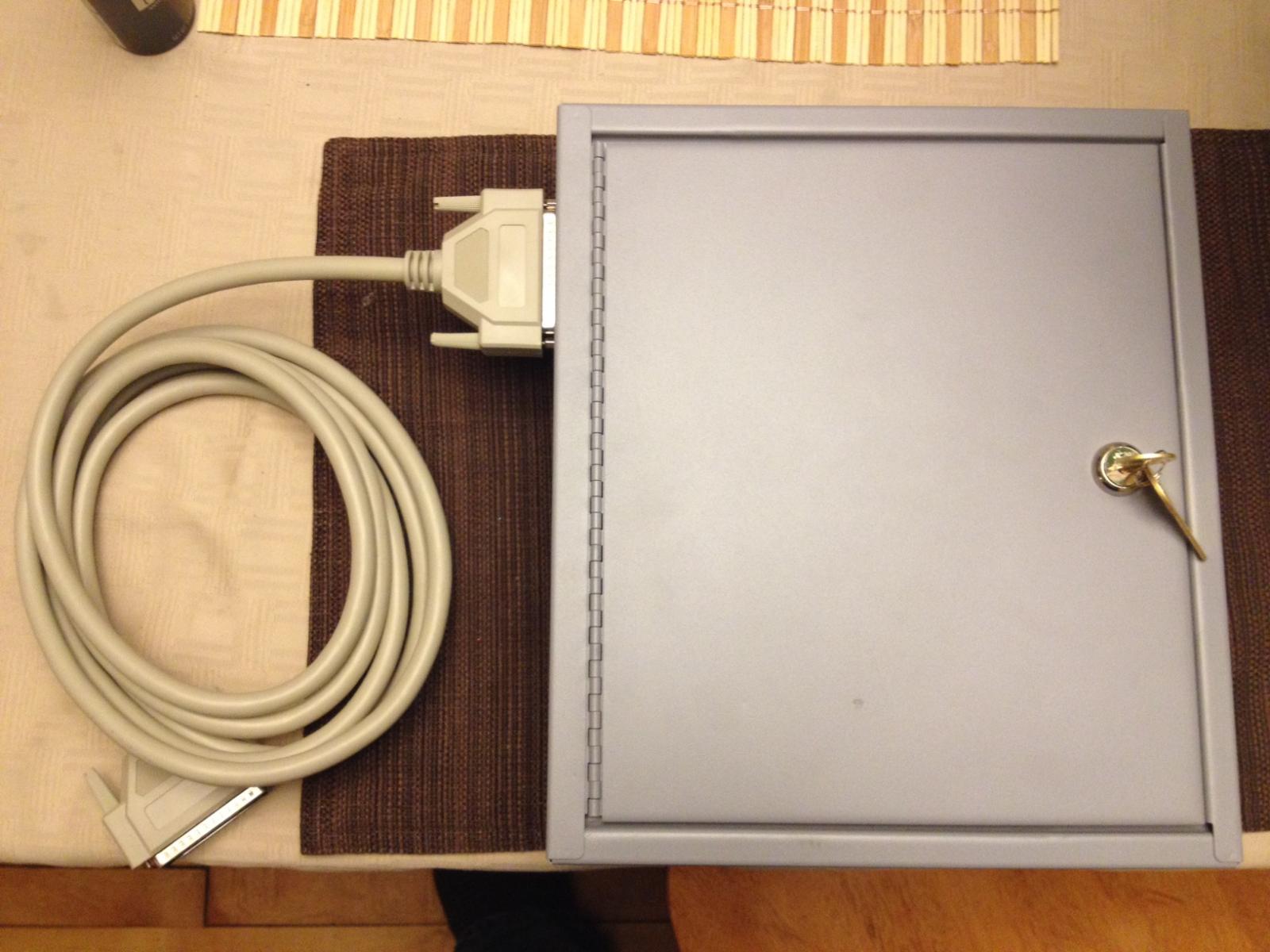

I installed the DB50 connectors on my panel and sub panel (had to get creative to mount the female to female gender changers without buying additional hardware). I was worried about using the small gauge wire with the valves (its 28 gauge wire in the DB cable I bought from

Amazon which is enough for 0.2amp of power transmission, the ball valves are 80ma at 12v), but I was able to test the ball valves with the cable assembly and my worries were relieved.

I am planning on using 4ch audio snakes to help clean up all of the wiring, and its cheaper than doing individual small length cables - I picked up a few of these

4 Channel 3' XLR Snakes

Thats all I got for now. I brewed a RyePA yesterday. Put the plate chiller to use. I was able to chill 6.5-7 gallons of wort down to 52 (oops) in out ~6 minutes, this was gravity fed, I will put the pump to use next time...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)