mliptack

Well-Known Member

I would just wire the N/O float switch in series between BCS output and SSR input. Prevents a dry-fire regardless of how/who tries to send power to it.

That was my initial thought, but I would only be able to use the float for one device, in which case I would need to put 2 floats in each kettle. My thinking is, I would like the same float to kill power to the heating element and the pump. At this point it would require human intervention to run the pump until completion (I am thinking about adding a momentary push button along with the 3-way selector for this).

With the ladder logic, I figured out a way to do it, but it probably is over complicated (and it wastes an output per device I want to have protected)

Example: HLT Heating Element Protect

Rung0 - Out0 (Wasted out) - Float DIN0 - - - - - OUT15 (SSR for Heat Element)

I would trigger Out0 in all my programs etc. and only if DIN0 is closed will it trigger power to the Heating Element. Of course the risk is accidentally triggering Out17 from the Main Control.

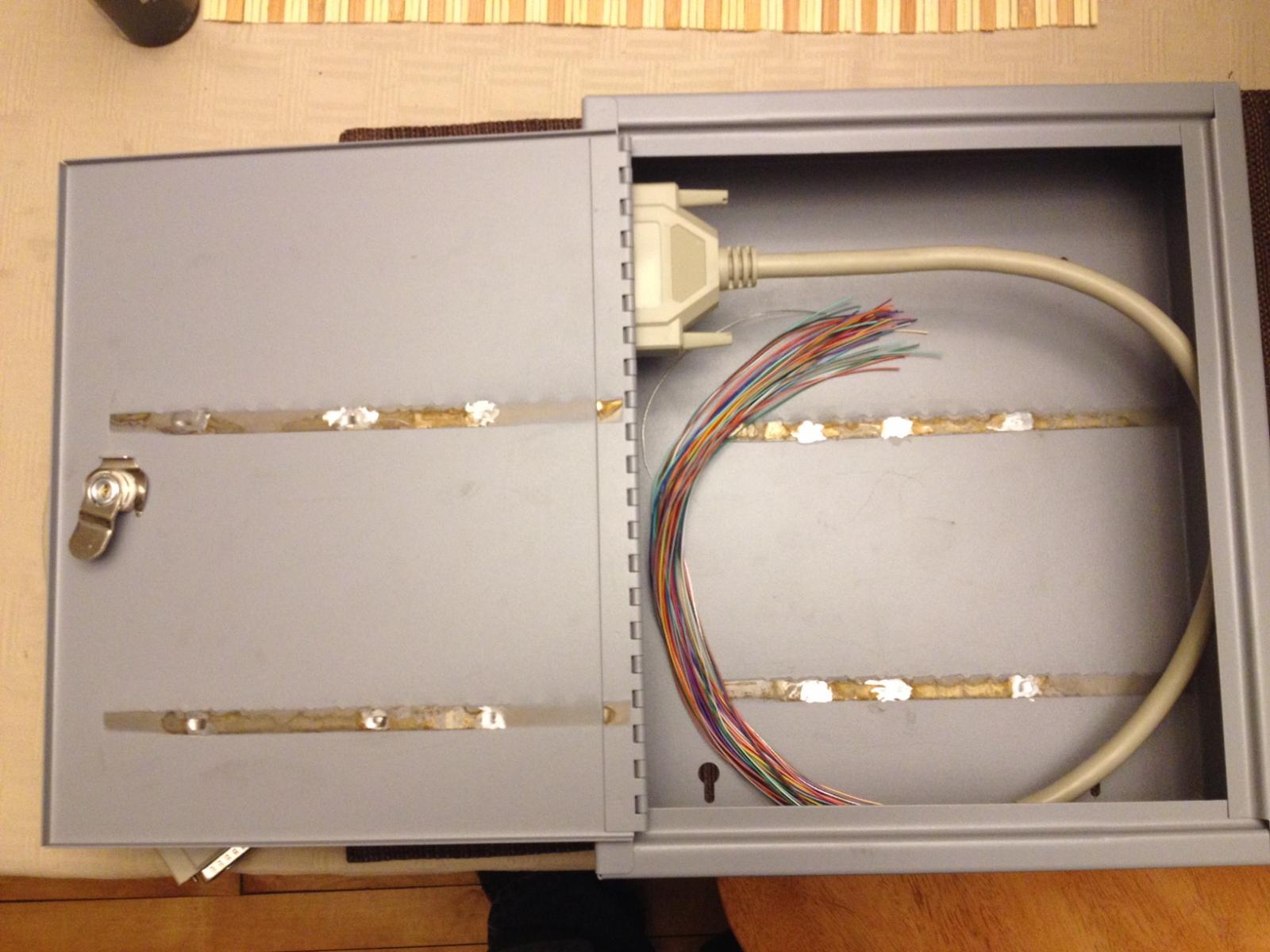

I just looked over your schematic and wondered the reasoning behind wiring the SSRs on same output in series?

MrNatural - You are very observant, thank you for taking the time to review the schematic and giving me feedback!

That is more of a remnant from an original design that didn't use a contactor for each element, instead, I would rely solely on the SSRs or the main contactor to kill power to the elements. For safety I decided to add the contactors, but never removed the SSRs from the design, because I already have them mounted to a heatsink in my panel.

Really there's no point in adding the additional heat of the 2 extra SSRs that serve no purpose (other than greater complexity). I think I will leave the 2 extra in place as spares, or for any other purpose that may arise.

Thanks for the questions! Cheers!

Max

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)