cuda6pak,

Would you mind giving me a few pointers on this please? I have a couple of medium BIACs and it would be good to have an 'all-in-one' solution for heating/cooling, in some instances to the two of them in tandem (assuming that I want to run them at the same temperature at the same time). I brew in my shed, where the ambient temperature throughout the year ranges from about 2 - 30°C (36 - 86°F).

Does this bit of kit serve to get down from boil to pitching temperature, or are you more likely to use municipal water to get down to, say, 30°C and then swap over for the final push?

How noisy are these units (I currently have an old shelf chiller that I picked up cheap, but it makes a right old racket)?

Am I likely (when cooling) to need to expel the heat produced to the outside on particularly hot days?

Any help would be appreciated.

I always bring it down to 100F by municipal water before switching over to the TK2000.

The units are fairly quiet, basically just a fan that kicks on along with the compressor when it's in cooling mode. Heat mode it makes no noise. Only noise would be from your pump of choice that is circulating the water.

This depends on what you are doing. If you are simply maintaining fermentation temperature, you will not have a problem. Even with the TK-500 and two medium BIACs in tandum with a regular sized cooler you should not have an issue. The problem with the size of the unit and heat expelling in a small room only becomes an issue when you are trying to cold crash on the hottest parts of the year. Now, if you're not trying to cold crash, but simply maintain fermentation temperature, you would be fine with a TK500 or even TK1000.

If you are planning on cold crashing, I would go with the TK2000 for sure. When it gets to those really hot days that thing will be running full bore to get the beer down to 40F or so, and if all that heat was being expelled into a small shed, I could foresee problems getting down to the temp you want. The garage I used to brew in would get to 90F during the summer, and when cold crashing it would get even hotter in there and struggle a bit.

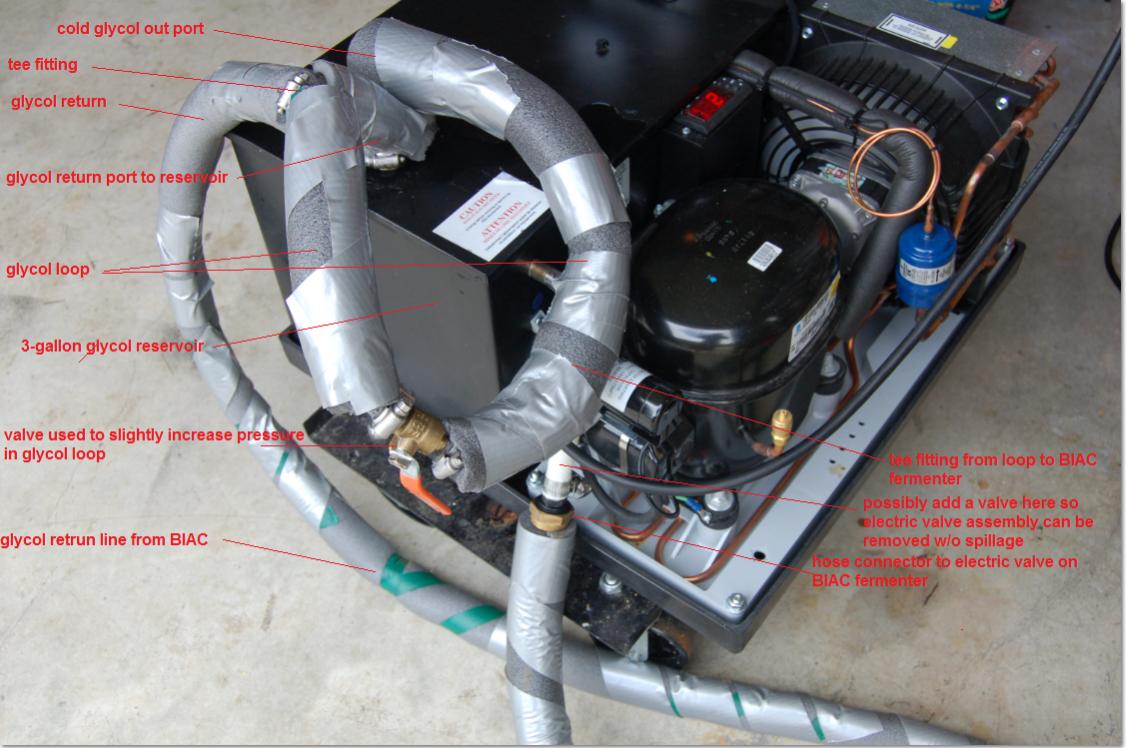

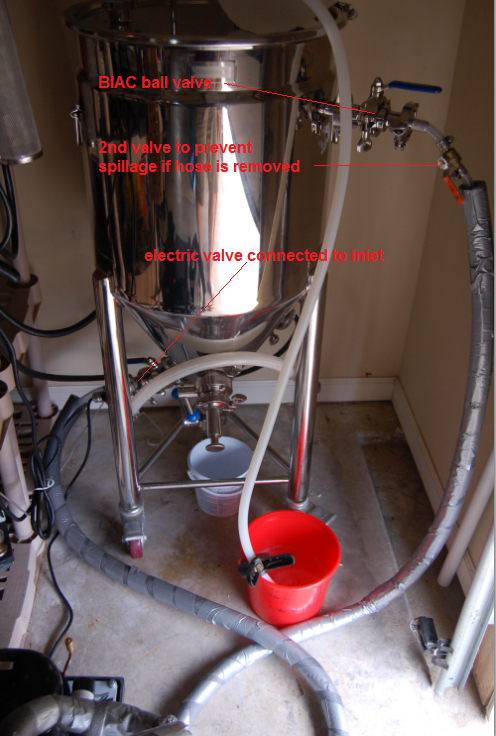

Another thing you can do to help is insulate the lines coming to/from the TK and cooler, as well as a neoprene jacket that Nathan sells.

Now, having said all that, with the new digital power box Nathan sells as well as the Glycol unit which is around $1k or the same price as a TK2000, I'd be hard pressed not to go with the glycol unit and put the digital power box at 1% for heating. But, you will also need to remember that even if you drain the glycol from the jacket after cold crashing, if you use municipal water there will still be some glycol mix left in the jacket, albeit not much, but something to consider.

When I bought my medium BIAC it came with the old analog power box, hence my current setup today.

If you search my posts in this thread you can see all the different combinations I tried - TK500, TK2000, both in tandem, insulated lines, half-ass neoprene jacket, and what I was able to do to give you an idea.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)