The electric 7bbl system sold by Stout includes a flow meter for strike water. However, they don't have it listed as an individual item on their website. I also checked Brewmation, the manufacturer of the electric control panel for Stout. They also sell the same 7bbl system but do not show the flow meter as an individual item for purchase.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-in-1 "Boil Kettle, Jacketed Chiller, Conical Fermenter" by Brewha

- Thread starter MeetsCriteria

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Same one at Home Depot and the company states safe for potable water.

good to know.

- Joined

- Nov 1, 2010

- Messages

- 344

- Reaction score

- 28

good to know.

Scratch that, I just re-read it again this morning. It states that it is exclusively for OUTDOOR USE ONLY. Use it pre-filter with a carbon filter and I would assume it would be alright. Using the filter the flowrate should be slow enough anyways. If it were me, I would use it. Many times I used a regular garden hose in the past to fill my kettles when I was first starting out. There is plenty of tubing that is used that isn't "Food Grade" as you alluded to earlier. One of them being the common siphon tubing.

Not that this makes it right to use a non food grade rated plastic...but I have been in more small craft breweries than I can count that use plastic boat paddles to stir mash. In my mind, using my little 2" long water meter with cold water is not as bad as a plastic boat paddle to stir 160F water. For example:

[ame]https://www.youtube.com/watch?v=JzLtmIA0LEE[/ame]

[ame]https://www.youtube.com/watch?v=JzLtmIA0LEE[/ame]

JB_Brewing2

Well-Known Member

Not that this makes it right to use a non food grade rated plastic...but I have been in more small craft breweries than I can count that use plastic boat paddles to stir mash. In my mind, using my little 2" long water meter with cold water is not as bad as a plastic boat paddle to stir 160F water.

I bought the same plastic flow meter and am unconcerned. As you stated, plastic is commonly used in mashes. The other options I saw, to go food grade, were significantly more expensive. Doubt this small plastic item will cause any issues. It's really nice to be able to measure down to the tenth of a gallon.

"The other options I saw, to go food grade, were significantly more expensive. "

IMHO, there is a reason for the price and I doubt it is just the plastic...I suspect there are sensor issues that must also be addressed to make it food grade...

IMHO, there is a reason for the price and I doubt it is just the plastic...I suspect there are sensor issues that must also be addressed to make it food grade...

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

Yeah, I wondered about the meter not being labeled for potable water. The meter itself is all plastic. There is no metal in the area that touches the water so at least I don't think I'll get lead poisoning. The plastic itself...??? Also, a lot of people use non-food grade plastic tubing in their brewing including their draft lines. I myself bought all proper beer grade stuff for my taps. I know we all use the silicone hose that came with our BIAC for transfers.

I initially connected the meter to the post filter end of my inline filter. I did that to keep any particulate in the water from getting into the little wheel and clogging it. Maybe, I'll move it to the pre-filter side. The inside of the meter is smooth and shiny and I use white potable water hose to connect. The entire meter is 3.25" long and the contact area is about 3"

It does have a CE mark and is manufactured in Taiwan instead of China. I don't know if that really makes a difference but as someone who has traveled to Taiwan for business, I can tell you Taiwan is definitely NOT China.

There is a symbol next to the CE mark that is a bit curious and I don't know exactly what it is. I searched for potable and non-potable water symbols and none look like this symbol.

I believe that symbol is the "Do not dispose in household waste" symbol.

JB_Brewing2

Well-Known Member

Wow... Not being food grade, saying for outdoor use only, and do not dispose of in household waste symbol and you all still want to use these in your system?

The symbol indicating this should not be disposed in household waste is due to the electronics and battery inside which indicates it should be recycled.

Sorry, I don't subscribe to hypochondriasis. Worked great! How do you measure water in your BIAC?

Wow... Not being food grade, saying for outdoor use only, and do not dispose of in household waste symbol and you all still want to use these in your system?

Mine does not say for outdoor use only. It even has a CE mark but that is probably regarding the electronics. See photo in post 680. Also, you can look at breweries all over youtube and see real 7bbl breweries not just little 1bbl nanos using plastic boat paddles to stir their hot mash. I always wonder about that myself, but there are some who have done it for years. A lot of people use plastic buckets, pumps and plastic tubing that are not food grade. I"m sure we can all go into our kitchens and find plastic and ceramic-type items that were made in China from who knows what. Yeah it doesn't make it right but if you examine this little gauge you would see it is a very small pathway and completely smooth. It is also accurate and a whole lot easier to use than the stainless steel ruler that hangs on the side of my medium BIAC.

JB_Brewing2

Well-Known Member

About two weeks ago I started brewing 10 gallons of a rye ale. When it came time to chill the wort, I began normally with a sanitized rag covering the blow-off tube opening with the valve in the open position and took it down to 68F. When I opened the lower side valve to take a sample for measuring SG, all I received was gurgling from the valve and the temperature on the TC increased from 68F to 75F. I checked the blow-off valve and had a gush of air sucked in when I opened it. To say the least, I was resigned to buying a new jacketed conical base. The bonehead mistake I made was to install the handle on the valve controlling the blow-off tube 90 degrees off! The valve handle indicated the valve was open the entire time I chilled when in fact it was closed. I had nightmares for two weeks thinking I had damaged the jacket by creating a vacuum which we all know can be detrimental to our BIAC's. Kegged the batch last night and to my amazement - no damage! I'm thinking the keg racking post, which was installed on the other port on the lid, was opened by the vacuum and relieved enough pressure to avoid damage. ??? Lesson learned: Double check my valve assembly. My next brew will be after I receive the vacuum safety valve with filter from Nathan.

Yeah, the vacuum thing scares me too. I brewed a pumpkin ale last night and I always install a valve on each port on the lid. During the chill, I open both with paper towel over each one held in place by twist ties.

BTW, I bought a sample valve from glacier tanks and I install it on the racking port. I usually have to purge a little crap into a bucket before I install the sample valve. Then I get a good clear sample for gravity testing.

BTW, I bought a sample valve from glacier tanks and I install it on the racking port. I usually have to purge a little crap into a bucket before I install the sample valve. Then I get a good clear sample for gravity testing.

Pumpkin beer on November 19??? I'm almost annoyed that I brewed two 10 gallon batches this year...ran out of kegs!

I also intend to buy the vacuum safety valve at some point, just in case. Glad to see your All-in-1 came out safe though.

I've been meaning to get a custom Jaybird false bottom built, but I think I may try a Brew Bag first. Brew last weekend was an Imperial Oatmeal IPA with Marris Otter and 18% oats. Needless to say it was an extremely sticky mash and I basically had to trickle the recirc and even at times it would just stop or I would have to stop it to keep from overflowing. Took 2 hours to fully drain after setting the mash colander up, normally it's done in 10-15min. For $30 I'll try out the bag and see how it does. I'd love to be able to recirc at nearly full bore.

I also intend to buy the vacuum safety valve at some point, just in case. Glad to see your All-in-1 came out safe though.

I've been meaning to get a custom Jaybird false bottom built, but I think I may try a Brew Bag first. Brew last weekend was an Imperial Oatmeal IPA with Marris Otter and 18% oats. Needless to say it was an extremely sticky mash and I basically had to trickle the recirc and even at times it would just stop or I would have to stop it to keep from overflowing. Took 2 hours to fully drain after setting the mash colander up, normally it's done in 10-15min. For $30 I'll try out the bag and see how it does. I'd love to be able to recirc at nearly full bore.

By the way, did anyone else see that they are now building BIAC setups up to 10bbl for microbreweries that will be able to withstand carbing pressure? That's a game changer IMO - Heat, mash, boil, ferment, carb, and serve all from the same tank. With 4-5 of them you could easily support a brewpub.

About two weeks ago I started brewing 10 gallons of a rye ale. When it came time to chill the wort, I began normally with a sanitized rag covering the blow-off tube opening with the valve in the open position and took it down to 68F. When I opened the lower side valve to take a sample for measuring SG, all I received was gurgling from the valve and the temperature on the TC increased from 68F to 75F. I checked the blow-off valve and had a gush of air sucked in when I opened it. To say the least, I was resigned to buying a new jacketed conical base. The bonehead mistake I made was to install the handle on the valve controlling the blow-off tube 90 degrees off! The valve handle indicated the valve was open the entire time I chilled when in fact it was closed. I had nightmares for two weeks thinking I had damaged the jacket by creating a vacuum which we all know can be detrimental to our BIAC's. Kegged the batch last night and to my amazement - no damage! I'm thinking the keg racking post, which was installed on the other port on the lid, was opened by the vacuum and relieved enough pressure to avoid damage. ??? Lesson learned: Double check my valve assembly. My next brew will be after I receive the vacuum safety valve with filter from Nathan.

Why install a valve on the lid at all? I never use a valve on the lid.

On one port I use a hose barb triclover fitting connected directly to the lid, with a hose running into a jug of starsan. The second port either has a PRV or ball lock fitting installed.

Eliminating the valve will essentially prevent the possibility of a vacuum or pressure buildup from ever happening.

Pumpkin beer on November 19??? I'm almost annoyed that I brewed two 10 gallon batches this year...ran out of kegs!

I also intend to buy the vacuum safety valve at some point, just in case. Glad to see your All-in-1 came out safe though.

I've been meaning to get a custom Jaybird false bottom built, but I think I may try a Brew Bag first. Brew last weekend was an Imperial Oatmeal IPA with Marris Otter and 18% oats. Needless to say it was an extremely sticky mash and I basically had to trickle the recirc and even at times it would just stop or I would have to stop it to keep from overflowing. Took 2 hours to fully drain after setting the mash colander up, normally it's done in 10-15min. For $30 I'll try out the bag and see how it does. I'd love to be able to recirc at nearly full bore.

Ha! I've had the ingredients to brew the pumpkin ale since late summer. I have global responsibility and work always gets in the way!

JB_Brewing2

Well-Known Member

Why install a valve on the lid at all? I never use a valve on the lid.

On one port I use a hose barb triclover fitting connected directly to the lid, with a hose running into a jug of starsan. The second port either has a PRV or ball lock fitting installed.

Eliminating the valve will essentially prevent the possibility of a vacuum or pressure buildup from ever happening.

Good point Jimmy. I ordered the PRV from Nathan and will not install a valve again on the blow-off. The valve was installed to provide more height for the blow-off tube. Thanks for the input.

Good point Jimmy. I ordered the PRV from Nathan and will not install a valve again on the blow-off. The valve was installed to provide more height for the blow-off tube. Thanks for the input.

Good stuff. Here is how I typically have it set up.

View attachment 1448222787610.jpg

I guess I'll have to buy a PRV. I use a ball valve on that port. When I'm crashing, I can place a paper towel soaked in sanitizer over the valve and give it a quick purge if needed but I almost never do. The one thing I always do is use a 90-degree barb on the blow-off side so I don't risk a hose kink.

xico

Well-Known Member

- Joined

- Jan 22, 2015

- Messages

- 328

- Reaction score

- 64

Is the pressure control valve for the jacket that Brewha sells the Sea Tec regulator? I'm having a lot of trouble finding one that controls such few pounds as 3 psi.

Edit:

Upon follow-up from Nathan and if others are curious about pressure regulation of the jacket it isn't necessary but a safety measure should pressure build on the outflow. Invest in reinforced hosing.

New questions:

I just brewed for the first time on my BIAC medium two days ago and I'm already trying to get through the week to brew my next batch. I have a couple questions from the community to find out what I can do to get more from my system.

How do I calculate proportion? I added 12 gallons of strike water for an 8 gallon batch to account for grain absorption and no sparge. Pre boil was at 10 gallons and somehow after boil and cooling I had 6.88 gallons. I know volumes of water shift with temperature but how can I handle my water control? I got pretty poor extraction efficiency which is in part due to my water quality and the lack of appropriate salts or acidulated malt.

Do people sparge instead?

How do you handle hops usage with the BIAC. I used about 5 ounces of hops in my last batch and the trub was a big mess. I don't want to melt nylon using a hop bag near that element. What do you use to keep some of the plant matter out of the trub post cooling?

Thanks in advance!

Edit:

Upon follow-up from Nathan and if others are curious about pressure regulation of the jacket it isn't necessary but a safety measure should pressure build on the outflow. Invest in reinforced hosing.

New questions:

I just brewed for the first time on my BIAC medium two days ago and I'm already trying to get through the week to brew my next batch. I have a couple questions from the community to find out what I can do to get more from my system.

How do I calculate proportion? I added 12 gallons of strike water for an 8 gallon batch to account for grain absorption and no sparge. Pre boil was at 10 gallons and somehow after boil and cooling I had 6.88 gallons. I know volumes of water shift with temperature but how can I handle my water control? I got pretty poor extraction efficiency which is in part due to my water quality and the lack of appropriate salts or acidulated malt.

Do people sparge instead?

How do you handle hops usage with the BIAC. I used about 5 ounces of hops in my last batch and the trub was a big mess. I don't want to melt nylon using a hop bag near that element. What do you use to keep some of the plant matter out of the trub post cooling?

Thanks in advance!

Is the pressure control valve for the jacket that Brewha sells the Sea Tec regulator? I'm having a lot of trouble finding one that controls such few pounds as 3 psi.

Edit:

Upon follow-up from Nathan and if others are curious about pressure regulation of the jacket it isn't necessary but a safety measure should pressure build on the outflow. Invest in reinforced hosing.

New questions:

I just brewed for the first time on my BIAC medium two days ago and I'm already trying to get through the week to brew my next batch. I have a couple questions from the community to find out what I can do to get more from my system.

How do I calculate proportion? I added 12 gallons of strike water for an 8 gallon batch to account for grain absorption and no sparge. Pre boil was at 10 gallons and somehow after boil and cooling I had 6.88 gallons. I know volumes of water shift with temperature but how can I handle my water control? I got pretty poor extraction efficiency which is in part due to my water quality and the lack of appropriate salts or acidulated malt.

Do people sparge instead?

How do you handle hops usage with the BIAC. I used about 5 ounces of hops in my last batch and the trub was a big mess. I don't want to melt nylon using a hop bag near that element. What do you use to keep some of the plant matter out of the trub post cooling?

Thanks in advance!

I use BeerSmith to calculate my batches. You'll have to dial it in with some trial and error. My last batch, I had mine set to 70% efficiency and would up with an OG that was 11 points high. I also double milled my grain using a 3-roller Kegco Mill at the factory setting. I usually crash cool with my glycol chiller and then transfer to a keg to carbonate. When I want to brew another batch soon, I transfer into a SS Brewtech Brewbucket for secondary fermenting. That frees up the BIAC for a new brew.

I use the hop basket that came with mine. For 5 gal batches that are a bit hop heavy, I use a piece of stainless wire that allows me to lower the basket more into the wort.

JB_Brewing2

Well-Known Member

Is the pressure control valve for the jacket that Brewha sells the Sea Tec regulator? I'm having a lot of trouble finding one that controls such few pounds as 3 psi.

Edit:

Upon follow-up from Nathan and if others are curious about pressure regulation of the jacket it isn't necessary but a safety measure should pressure build on the outflow. Invest in reinforced hosing.

New questions:

I just brewed for the first time on my BIAC medium two days ago and I'm already trying to get through the week to brew my next batch. I have a couple questions from the community to find out what I can do to get more from my system.

How do I calculate proportion? I added 12 gallons of strike water for an 8 gallon batch to account for grain absorption and no sparge. Pre boil was at 10 gallons and somehow after boil and cooling I had 6.88 gallons. I know volumes of water shift with temperature but how can I handle my water control? I got pretty poor extraction efficiency which is in part due to my water quality and the lack of appropriate salts or acidulated malt.

Do people sparge instead?

How do you handle hops usage with the BIAC. I used about 5 ounces of hops in my last batch and the trub was a big mess. I don't want to melt nylon using a hop bag near that element. What do you use to keep some of the plant matter out of the trub post cooling?

Thanks in advance!

I did invest in the reinforced hose but also want ultimate safety with the PRV.

Regarding your question about water volumes, I too have been playing with Beersmith to dial in the right amount and have yet to get it exactly right after a half dozen brews. Brews have been great and the last one hit the numbers exactly just a little less volume though. Perhaps one of our other BIAC'ers will chime in on how they handle it.

Recently, I added another rigid SS hop basket from the local HBS to the two hop baskets I received when I ordered the BIAC from Nathan. To ensure full utilization of the hops, I've been attaching a length of SS wire to each basket and acquire full submersion that way.

Hope this helps.

Wow guys, I am amazed at how quickly my glycol system crashed my beer today. The ambient temp is about 50 outside right now and the garage temp is 62F. I crashed in a couple of steps from 68-55, then 55-45. In the summer, the chiller would have taken hours to get to 55 with all the humidity. I did not time it but I'm sure it was less than 2hrs total today and there is zero condensation. Now, I'm taking it down to 40F.

xico

Well-Known Member

- Joined

- Jan 22, 2015

- Messages

- 328

- Reaction score

- 64

Wow guys, I am amazed at how quickly my glycol system crashed my beer today. The ambient temp is about 50 outside right now and the garage temp is 62F. I crashed in a couple of steps from 68-55, then 55-45. In the summer, the chiller would have taken hours to get to 55 with all the humidity. I did not time it but I'm sure it was less than 2hrs total today and there is zero condensation. Now, I'm taking it down to 40F.

so are you using a pump for the glycol system? i don't know how chillers work but i've been afraid of attaching my chugger to the jacket. my hope is to recirculate ice water as the cooling time seems to be at about 1 hour and 45 minutes for the last two brews. that's a lot of wasted water and a lot of time not spent doing other things (including potentially a second brew). can the jacket handle a chugger at full throttle so long as the outflow is unimpeded with a short reinforced hose?

congrats on your new upgrades! lots of great ideas in this thread to look towards.

so are you using a pump for the glycol system? i don't know how chillers work but i've been afraid of attaching my chugger to the jacket. my hope is to recirculate ice water as the cooling time seems to be at about 1 hour and 45 minutes for the last two brews. that's a lot of wasted water and a lot of time not spent doing other things (including potentially a second brew). can the jacket handle a chugger at full throttle so long as the outflow is unimpeded with a short reinforced hose?

congrats on your new upgrades! lots of great ideas in this thread to look towards.

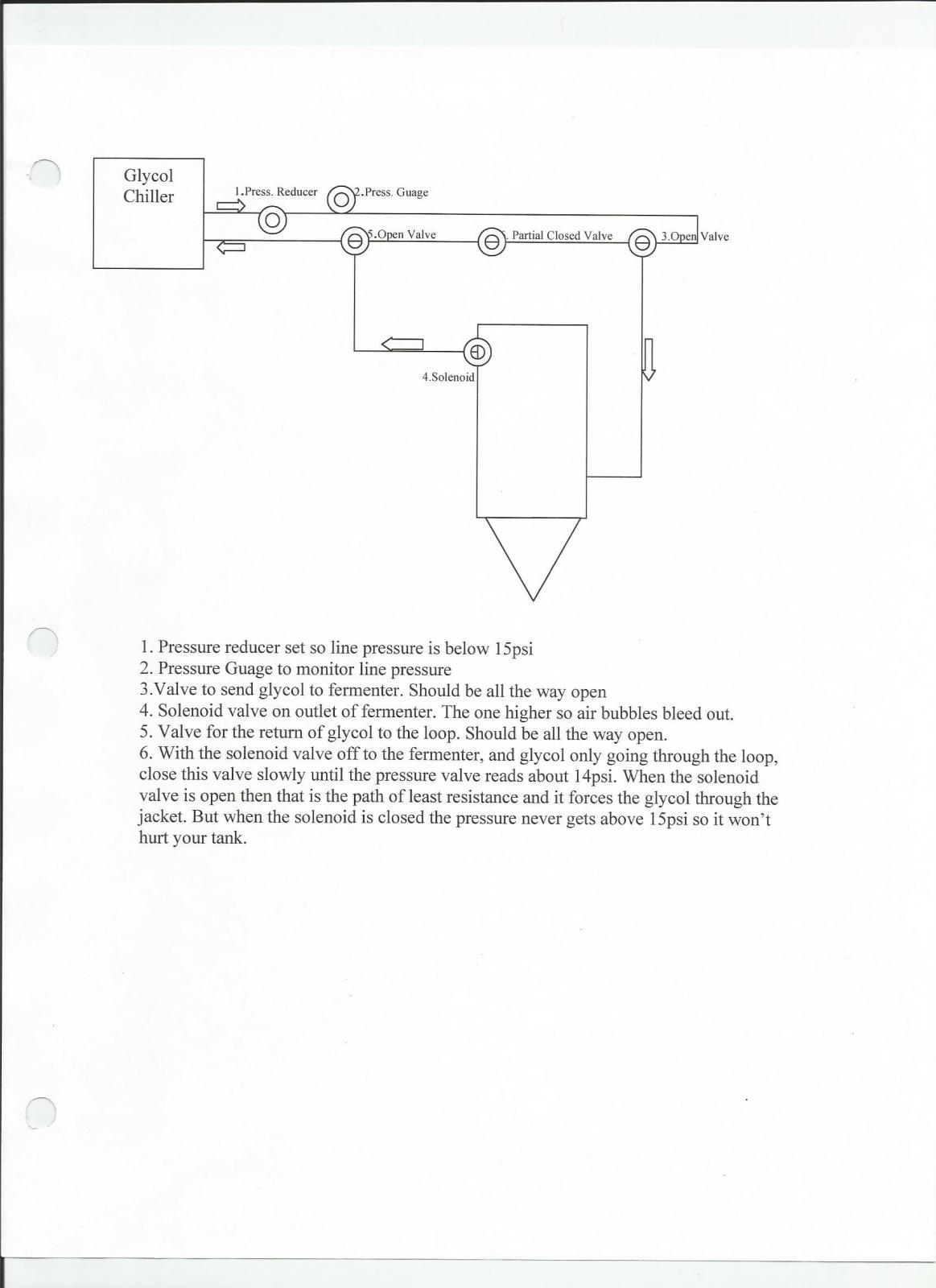

Glycol chillers have pumps. I built a recirculating loop using the electric valve that came with the BIAC. When the BIAC conroller senses the the temp is too high, it opens the valve and the cold glycol/water solution follows the path of least resistance and flows through the open valve into and out of the BIAC jacket. The recirculation pump on the chiller constantly pumps glycol through the loop and there is a valve on the return end of the loop that is just slightly closed to create just a little pressure. When the BIAC electric valve opens, that creates the path of least resistance. I attached a drawing of a glycol loop.

REgarding the Chugger, I don't run any kind of resistance on the jacket. When I was running my diy warm water circulation system, I used my old Chugger pump from my previous brewing setup and there is not problem. I think the biggest risk is from vacuums.

xico

Well-Known Member

- Joined

- Jan 22, 2015

- Messages

- 328

- Reaction score

- 64

I did invest in the reinforced hose but also want ultimate safety with the PRV.

Regarding your question about water volumes, I too have been playing with Beersmith to dial in the right amount and have yet to get it exactly right after a half dozen brews. Brews have been great and the last one hit the numbers exactly just a little less volume though. Perhaps one of our other BIAC'ers will chime in on how they handle it.

Recently, I added another rigid SS hop basket from the local HBS to the two hop baskets I received when I ordered the BIAC from Nathan. To ensure full utilization of the hops, I've been attaching a length of SS wire to each basket and acquire full submersion that way.

Hope this helps.

I also just ordered a 300 micron SS submersible hop basket to try and limit dump waste of cold break. I love the system but my biggest gripe is the cooling time. I broke the bank getting the system as it is and though a glycol system would be stellar (thank you limulus for sharing your diagram, I'm a visual person and this is a new area for me) it just isn't in the cards for me. I've been trying to figure out how to cool my wort to pitching temps that doesn't take 2 hours to do. Aside from the longer brew day as a result, I know there are issues of off flavors due to slow cooling. I am considering gravity feeding ice water from my cooler into the top port and collecting and re-pouring the water back into the cooler manually.

An idea a friend had was to hook up an immersion chiller to the tap line and from there attach the pressure regulator before hooking up to the jacket which is a pretty neat idea. I know I know, it defeats the purpose of the jacketed cooling system in introduce a chiller but at this point I might be off-flavors anyway by the long cooling process. I also love the whirlpool someone built in this thread but I don't know if I can afford that at present.

Also, it would be great to reuse the water from this process but upon reading the thread :

https://www.homebrewtalk.com/showthread.php?t=522909&page=12

I'm now aware of carbon soot in the jacket that I do not want in my beer, or me for that matter. Any thoughts on a way to clean it out effectively?

EDIT,

And one more question, I have a 3/4 inch barb fitting I think goes to the bottom port of the conical as I upgraded the dump valve to a larger one. Is that correct or is this going to the jacket output to avoid pressure from building on the outflow?

JB_Brewing2

Well-Known Member

I also just ordered a 300 micron SS submersible hop basket to try and limit dump waste of cold break. I love the system but my biggest gripe is the cooling time. I broke the bank getting the system as it is and though a glycol system would be stellar (thank you limulus for sharing your diagram, I'm a visual person and this is a new area for me) it just isn't in the cards for me. I've been trying to figure out how to cool my wort to pitching temps that doesn't take 2 hours to do. Aside from the longer brew day as a result, I know there are issues of off flavors due to slow cooling. I am considering gravity feeding ice water from my cooler into the top port and collecting and re-pouring the water back into the cooler manually.

An idea a friend had was to hook up an immersion chiller to the tap line and from there attach the pressure regulator before hooking up to the jacket which is a pretty neat idea. I know I know, it defeats the purpose of the jacketed cooling system in introduce a chiller but at this point I might be off-flavors anyway by the long cooling process. I also love the whirlpool someone built in this thread but I don't know if I can afford that at present.

Also, it would be great to reuse the water from this process but upon reading the thread :

https://www.homebrewtalk.com/showthread.php?t=522909&page=12

I'm now aware of carbon soot in the jacket that I do not want in my beer, or me for that matter. Any thoughts on a way to clean it out effectively?

EDIT,

And one more question, I have a 3/4 inch barb fitting I think goes to the bottom port of the conical as I upgraded the dump valve to a larger one. Is that correct or is this going to the jacket output to avoid pressure from building on the outflow?

Glycol chillers are pretty neat and expensive. I don't have one either and not sure I need one. In Michigan, I'm more concerned with maintaining warmth during fermentation. The ambient temperature of the municipal water I use is ~52 degrees and I last chilled a 10 gallon batch of IPA in 45 minutes (from 212 to 68 degrees). I maintain 3psi from the tap to the jacket and have an unimpeded outflow to my utility sink. I understand that others will experience longer chill times the higher the ambient temperature of the water, but I'm pleased with my chilling time and haven't experienced any notable off-flavors.

I use the original valve at the lowest point on the conical as I've adapted a mason jar with a silver-soldered tri-clamp lid to dump trub and collect yeast. (https://www.homebrewtalk.com/showthread.php?t=510704) Also, I use the same valve to connect the oxygenation stone to aerate the wort prior to pitching.

On my first batch I had some small black pieces exit the jacket but its been clean ever since. Never worried about it getting into the wort since the jacket is isolated from the inner boil kettle.

I've been using significant quantities of whole leaf hops in hop baskets and have not had an issue dumping trub or collect yeast. I have had an issue with the lower side valve clogging when racking over to a keg. Solved that by putting a small amount of pressure in the keg and then opening the valve. I get a small burst of CO2 that clears the valve and then allows unimpeded flow to the keg when I turn on the CO2 connected to the keg racking post on the lid.

xico

Well-Known Member

- Joined

- Jan 22, 2015

- Messages

- 328

- Reaction score

- 64

Thanks Guys. I live on a golf course and there is no place to dump grain. It would be severely frowned upon. I also live on a corner lot with a side entry garage. Every single neighbor who drives by seems to constantly stare into my garage. I guess they wonder what the hell I'm doing in there. At least the BIAC is electric and I can keep the doors closed or just partially open.

I would be afraid that dumping the grain would attract rodents and then snakes and every other kind of varmint. Right now, I use my electric winch to lift the mash and then I lower it into a tote until I"m ready to empty it. I then empty it into a large heavy duty contractor grade garbage bag and tie it tightly. Then it goes into the trash bin. I wish I had a place to compost. I will try to use the hose for cleaning from now on. It is just too big for the kitchen sink!

It's a stretch but are there any people with chickens or pigs in your area? Our flock devours about 25 pounds (dry pre-mash weight) of grain in less than a week. There might be someone who would kick you some eggs every so often if they can supplement feed and scratch grain for them. I we weren't brewing I'd happily exchange eggs for feed as input for a flock adds up month after month. With pigs, you might be able to barter for some pork, yum.

xico

Well-Known Member

- Joined

- Jan 22, 2015

- Messages

- 328

- Reaction score

- 64

Glycol chillers are pretty neat and expensive. I don't have one either and not sure I need one. In Michigan, I'm more concerned with maintaining warmth during fermentation. The ambient temperature of the municipal water I use is ~52 degrees and I last chilled a 10 gallon batch of IPA in 45 minutes (from 212 to 68 degrees). I maintain 3psi from the tap to the jacket and have an unimpeded outflow to my utility sink. I understand that others will experience longer chill times the higher the ambient temperature of the water, but I'm pleased with my chilling time and haven't experienced any notable off-flavors.

I use the original valve at the lowest point on the conical as I've adapted a mason jar with a silver-soldered tri-clamp lid to dump trub and collect yeast. (https://www.homebrewtalk.com/showthread.php?t=510704) Also, I use the same valve to connect the oxygenation stone to aerate the wort prior to pitching.

On my first batch I had some small black pieces exit the jacket but its been clean ever since. Never worried about it getting into the wort since the jacket is isolated from the inner boil kettle.

I've been using significant quantities of whole leaf hops in hop baskets and have not had an issue dumping trub or collect yeast. I have had an issue with the lower side valve clogging when racking over to a keg. Solved that by putting a small amount of pressure in the keg and then opening the valve. I get a small burst of CO2 that clears the valve and then allows unimpeded flow to the keg when I turn on the CO2 connected to the keg racking post on the lid.

I love the jar build for yeast collection, what a fantastic idea! Thanks for the advice with transfers from the conical too, I will follow your advice using the keg as valve clearer. My next brews will be Saturday and Sunday to try to dial in the system's quirks.

JB_Brewing2

Well-Known Member

I love the jar build for yeast collection, what a fantastic idea! Thanks for the advice with transfers from the conical too, I will follow your advice using the keg as valve clearer. My next brews will be Saturday and Sunday to try to dial in the system's quirks.

I also used this post to make the yeast harvester:

https://www.homebrewtalk.com/showthread.php?t=155782

It helped to understand silver soldering. I relied heavily on the earlier post though.

JB_Brewing2

Well-Known Member

Quick question to those of you in the US who have purchased something from Brewha: have you ever been charged a foreign transaction fee?

No foreign transaction fee was charged to me for delivery into the US. Shipping was expensive but reasonable given the distance and weight.

JB_Brewing2

Well-Known Member

I don't recall a transaction fee but I do remember something about providing my SS# to customs which I did not like at all.

I too had to provide my SSN for US Customs. Alternatively, if you have an IRS tax ID you can just provide the tax ID for the business. Like you, I'm never wild about giving out my SSN but I did call Nathan and give it to him personally to avoid any electronic interception.

Thanks guys. I was brewing a 5gal batch and I think the element ran dry when I was recirculating. There was a little over 8gal of water and that combined with what the grain absorbed was not enough water. From now on, I'll do no less than 8gal batches. I've done that already and had no trouble.

Sorry to reply to this old post but I've been going through this thread doing research on the BIAC and a thought occurred to me about the issue of ensuring that the element is covered and monitoring internal fluid levels.

Would it be possible to create a make-shift sight glass coming out of the racking port valve with a 90-deg TC-to-hose barb fitting and some tubing? You'd need to find a way to hold the tubing at the top on the exterior of the vessel but then you could mark off the critical water levels (and volume measurements) for future use. Since I don't have the 3-in-1 yet I don't know if the racking port is low enough for monitoring coverage to the element.

You could just pop it on temporarily for the mash or when using the condenser assembly for distillation.

I think I suggested a sight glass to Nathan. He has been pretty responsive to making changes or offering options. I'm sure you could probably make a sight glass using flexible tubing like I've seen in pro breweries.

Sorry to reply to this old post but I've been going through this thread doing research on the BIAC and a thought occurred to me about the issue of ensuring that the element is covered and monitoring internal fluid levels.

Would it be possible to create a make-shift sight glass coming out of the racking port valve with a 90-deg TC-to-hose barb fitting and some tubing? You'd need to find a way to hold the tubing at the top on the exterior of the vessel but then you could mark off the critical water levels (and volume measurements) for future use. Since I don't have the 3-in-1 yet I don't know if the racking port is low enough for monitoring coverage to the element.

You could just pop it on temporarily for the mash or when using the condenser assembly for distillation.

Similar threads

- Replies

- 1

- Views

- 477

- Locked

- Replies

- 15

- Views

- 3K

- Replies

- 17

- Views

- 3K

- Replies

- 7

- Views

- 2K

Latest posts

-

-

-

-

Spike Conical Heater fails again--second in 3 years--ideas?

- Latest: Indian_villager

-

-

-

-

For Sale Father's Passing: Homebrew Equip. Mega Sale

- Latest: leedspointbrew