JB_Brewing2

Well-Known Member

I've never enjoyed better or more responsive customer service than Nathan has provided...even after the sale! Really pleased with my decision to buy from Brewha.

I've never enjoyed better or more responsive customer service than Nathan has provided...even after the sale! Really pleased with my decision to buy from Brewha.

Nathan's offering a water pressure regulator which is out of stock right now. Was wondering if anybody is aware of a water pressure regulator/reducer that would allow one to reduce the pressure down to 3 psi? I'd also like to buy from the USA since shipping is still an issue for him. I've seen some for big bucks but am hoping for a less expensive version. Any one have a suggestion?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

I'm about to purchase a medium 3in1 and mash colander, and I'm wondering how everyone is chilling and maintaining fermentation temps. I've seen some people with glycol packs, and I'm assuming they can handle the wort chilling and fermentation duties, but for everyone else, how are you doing it? I have a walk in cooler at 40F that I was thinking I could put a reservoir in with water or glycol (any tips there?) and use a pump to recirculate to hold fermentation temps. I'm not sure if the 5-7 gallon volume I am considering is enough for initial chilling though. I have municipal water available for initial chilling, but it seems like it might be a pain to have to switch back and forth, especially if I choose to use glycol for fermentation.

Any thoughts or help?

Thanks,

Joe

I cool with tap water, and switch to the glycol chiller once it's dropped down to about 80 or 90*F. I don't run glycol in my chiller though, I just use water that is kept at target fermentation temperature and let it constantly recirculate through the jacket.

Thanks for the info, do you need to change out the water in your chiller periodically? I would think it would get a little nasty over time, but maybe its not an issue.

For chilling, I kept my 40-plate chiller and cart. I know that strays from the self contained system, but I was concerned about vacuums before the incident ever happened and I really can't say that I have read anything about avoiding vacuums on the Brewha site. I took a brewing course last year at a brewery in Colorado and the brewer there told me about vacuums. I'll be using a glycol system to keep mine at fermentation temp now that it is getting warm. I have not decided how I'm going to circulate through the jacket yet. But I do still have a copper immersion chiller that can be hooked up to the glycol system and then inserted into a water reservoir...at least I think I can do that. That water would be circulated through the jacket. The other solution is to just circulate directly from the glycol system. I'm definitely ordering a pressure valve for my jacket and I'm also looking at a vacuum release valve at glacier tanks.

1. Do not put any restriction or closure on the blow-off port in the lid of the 3-in-1 during chilling as a vacuum may form which could pull the walls in. (To prevent blow-off water from being sucked into the vessel, ensure that that volume of water in the trap, is less than the rising portion of your blow off hose can holdbefore the water is sucked over into the vessel, air will enter the hose and be drawn into the vessel rather than the water; another preventitive measure is to put a small amount of Star San into the blow off water to prevent microbial growth)

I have read through some of the chiller manuals, and they call for using a glycol water mixture to also serve as a lubricant.

Have there been any issues with regards to lubrication on water only use.

I am planning on keeping the jacket clean so I would not run any glycol through it. I plan on something like a silver serpent coil in a cooler as a resivoir and then reciculate from the resivoir through the jacket.

Has anyone used this method and have you been able to crash chill for lagers?

Thanks

I have read through some of the chiller manuals, and they call for using a glycol water mixture to also serve as a lubricant.

Have there been any issues with regards to lubrication on water only use.

I am planning on keeping the jacket clean so I would not run any glycol through it. I plan on something like a silver serpent coil in a cooler as a resivoir and then reciculate from the resivoir through the jacket.

Has anyone used this method and have you been able to crash chill for lagers?

Thanks

On your exhaust system, the 30 qt bowel, what is the diameter of the bottom? I see that the top is 22 inches, same size as the medium 3 in 1.

I like your set up and plan on doing something similar. I will use an angle ring bolted with high temp gasket caulk assembled to a duct system called gorilla duct, which will exhaust out the garage wall with a fantech exterior wall mount 8 inch duct size fan pulling just over 400 cfm. I will most likely reduce the 8 inch down to 6 prior to the bowel connection.

I will use the window for make up air as my furnace is oil fired and I do not want to backdraft the flue gas.

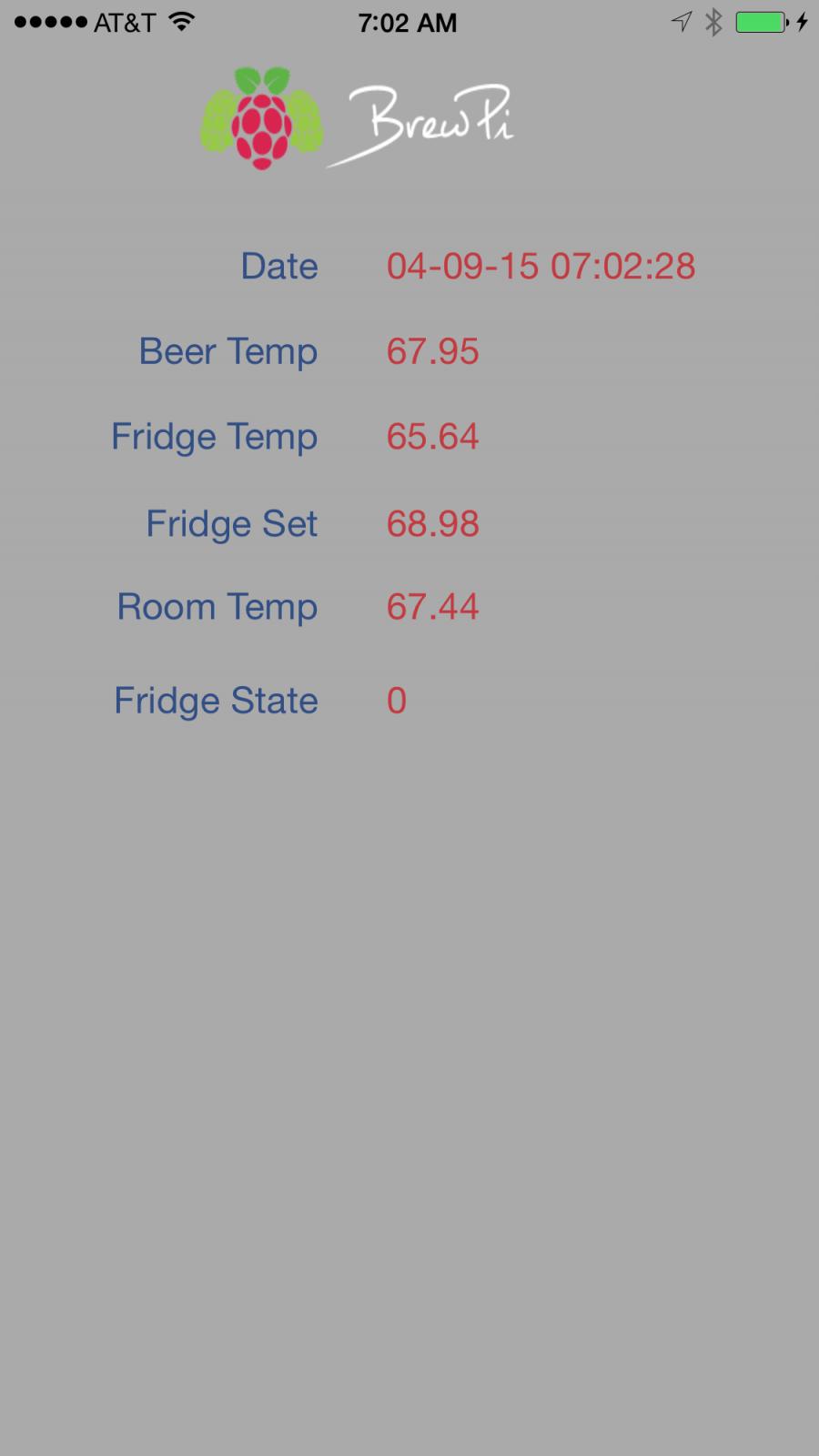

Love the BIAC, have made about 12 batches so far. I have a custom controller and I am using a BrewPi to ferment. Couldn't be easier.

-KnotAByte

My apologies if this has been asked and answered in the thread already. Are those of you with armed and operational Brewha systems using the element for the "hot side" of the temperature control during fermentation with the water/glycol jacket for the cool side? I thought I recall seeing mention of setting the element at 1%. Any issues that have been seen? I am thinking primarily for ramping up at the later stages of fermentation or for Belgian styles that like to finish much warmer.