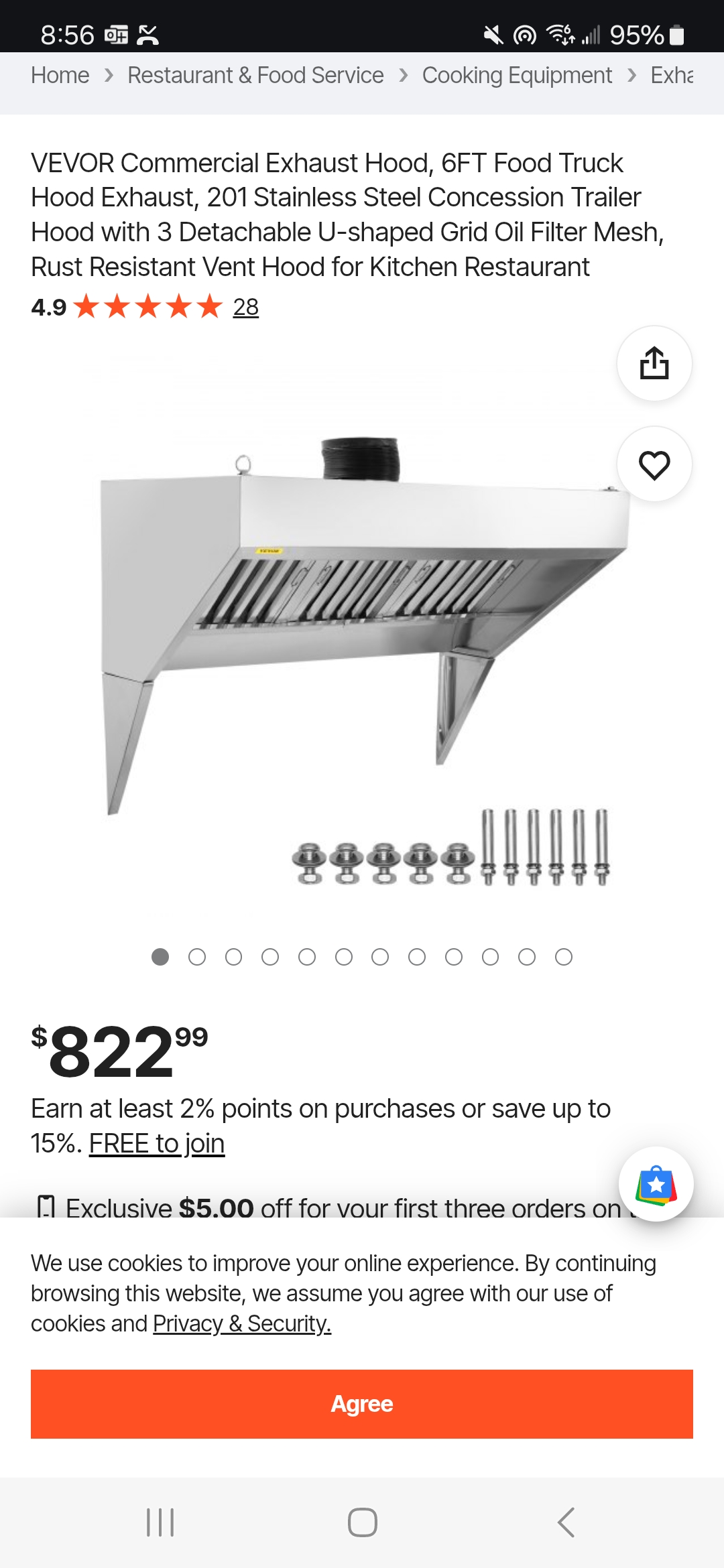

Probably directed at the OP, but it's reasonably priced for a commercial hood of that size. The grates, which are designed to capture grease and smoke, are a decent portion of the price. They are not necessary for brewing except perhaps they might be needed to properly capture condensation due to the grate angle vs the flat underside of the top. Thinking a bit, I kind of remember getting ceiling drips where improperly sized grates left a gap. What I don't see is a drip cup where the grease would drain to. I worked in multiple restaurants, in one we had to climb up at closing time and run the grates through the dishwasher, wipe down the hood, and empty the grease cup every night. The hood appears to have a drip channel around the interior including the sides. I use a wash cloth or half an old hand towel to wipe down with on my own hood, it's not that much moisture as far as a collecting cup.

The grates are meant to capture particulates and prevent fires. They seal the exhaust space forcing air travel through the channels. It's a good idea to keep the grease and other stuff out of the exhaust ducts in case of a fire. That's what you are paying for with these.

There's no fan mentioned at the Vevor site either, plus additional duct work and a wall or roof exhaust is needed too. For my half keg design, the transition piece off the hood to the duct would have been expensive to buy due to the curvature. I fabricated it myself. It seems something is attached to the Vevor model. You probablty will need a duct crimping tool too. A pair of needlenose pliers can work in a pinch. One end is crimped already on the ducts and fittings.