Your process, is exactly what I am setting up to do. I will be transferring through a ball valve also to underlet the grain - and then I have the RIMS tube and a manifold in the kettle.

FWIW, I consider a RIMS system to be a 3-vessel system: a boil kettle (1), a mash tun (2), and the RIMS tube (3). I don't see any difference, fundamentally, between a HERMS and a RIMS: both use a 3rd "vessel" to provide heat to the mash tun. One advantage to the RIMS setup is not needing that 3rd kettle, it reduces the space needed, no need to have an element in the mash tun.

You don't need to heat sparge water; cool water will work the same. The sugar is already dissolved into the wort, and all you're doing with sparging is rinsing that residual sugar water off the grain. The only advantage to heating sparge water is it's already at least some of the way toward boiling, and that will save a little time. But it's at best a minor advantage, IMO.

***********

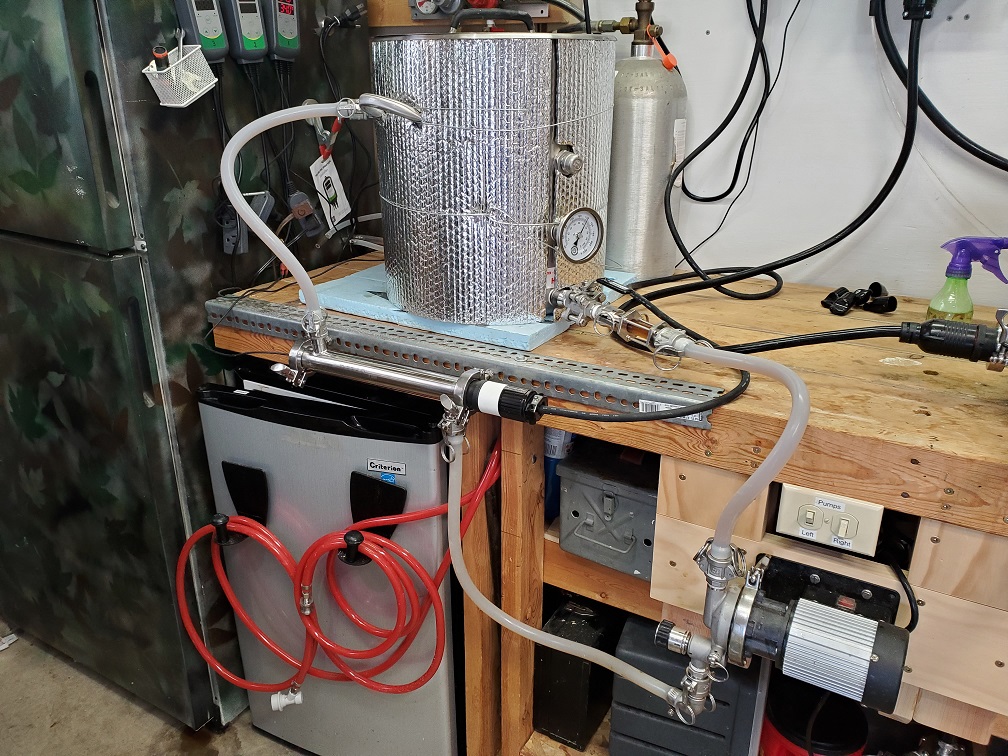

Here's my setup; may give you an idea or two as you set things up. Lots of ways to do this, and variations often depend on the space and resources available. It took me almost a year to figure this out; prior to that I was setting the pump on a wooden box, things were fiddly, and suddenly, after seeing someone else's setup it gave me the idea to do this.

I was trying to figure out how to shift the hoses in such a way that I wasn't having to move the pump and use a bunch of different hoses. What makes this a little different is I am using a counterflow chiller instead of maybe an immersion chiller.

When I heat the strike water, I boil it to drive off oxygen, then run that boiling water through the counterflow chiller. This sanitizes the chiller (it was already clean from last time, I'm just a little OCD about sanitation). Then I'll cool that water down to strike temp.

It's a little hard to see in this pic, but the hose coming out of the bottom of the pump is going into the counterflow chiller; it's hidden behind the other hose that comes out of the counterflow chiller and back to the kettle where the whirlpool valve is. When it's time to move that water into the mash tun, I just close the whirlpool valve, use a hemostat to close off the hose, and transfer it to the valve into the mash tun.

And yeah, it's sized in length to *just* reach.

Once the water is transferred, I close the MT valve, pinch off the hoses (hemostats), then take the hose that feeds the pump from the BK and transfer it to the MT, so that will feed the pump. The bottom hose out of the pump will be switched to the bottom of the RIMS tube, and a third hose will connect the top of the RIMS tube to the return manifold.

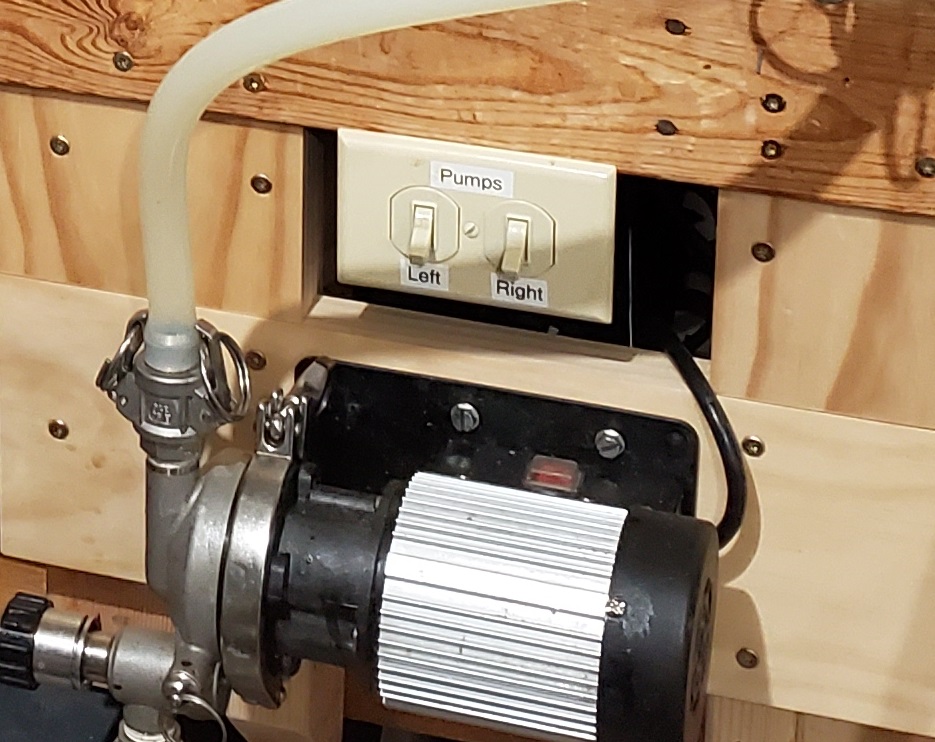

I used the pushbutton switches on my power panel to control my pump, but it's not in a particularly good spot--I have to reach. Finally dawned on me to use normal household switches to control that, and it's right there so it's as easy as can be to turn on and off. One switch controls the riptide pump; the other is connected to a MkII pump I use to clean my conical.

As I said, took me a year to finally figure out how to place everything so the hoses were switchable, everything reached, how to mount the pump (lower than the kettles so gravity would help prime it), and so on.

FWIW, also, here's the manifold:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)