beerspitnight

Well-Known Member

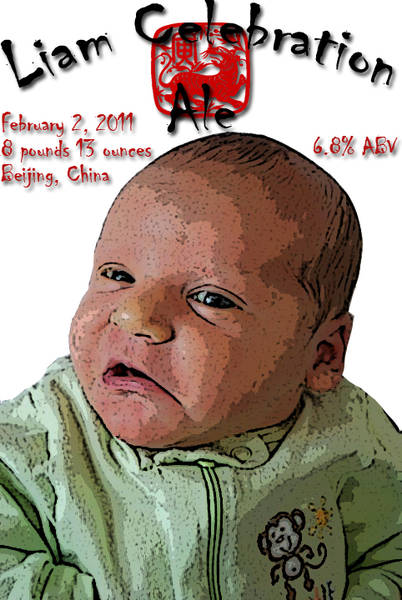

Three of us (1 seasoned brewer who helped my buddy and I, both virgins) got after our first AG brew yesterday (rough Celebration Ale for my 6 week old son). It was a long day, which started with getting the ingredients and then forgetting the NG tank, going back to get the NG tank, and then getting my Jeep stuck between two concrete walls way back inside a hutong. But we did get going and had a successful cherry popping first brew. Details below.

10 gallon batch - 80 min boil.

10kg of grain - 9kg of pale malt, 500g of cara red, and 500g of cara pils.

Hops - whole cascade at 1st boil, then qingdao flower at 20min, 40 min, 60min and cascade & qingdao flower for last 30 seconds.

We heated the sparge water (7 gal) and initial water for the LT (8g) on my buddy's stove. 1st pull reading was 1.083. Last pull reading was 1.012. Once we got 11 or so gallons in the boil pot we moved the bot outside to the NG burner, but the burner turned out to be crap. We did test it when we first got it, and we weren't too happy with the purchase, but we figured we would give it a shot since the stove was giving us a weak boil. Needless to say the NG burner didn't do all that well and the flame kept blowing out. So we moved back inside and settled for the stove. 30g of whole cascade went in straight away, followed by 30g of qingdao flower 20 min later and 30g 40 minutes in, 40 g 60 min in, and 10 g of qingdao flower and 30 g of whole cascade for 1 turn of the boil at the end .

We lost about 1 to 1.5 gallons of water with the extended time it took to get the wort to a boil.

We chilled in a ice bath in the tub and got down to 26c in about 2 hours. We racked to our fermenter while running the wort through a fine mesh strainer.

Mixed two packets of Fermentis Safale S-04 in 26c spring water, mixed and then pitched to fermenter.

We aren't using an airlock, just a lid that rests on the fermenter.

24 hours later and we have action.

Will update this as we go.

Next Time and Down the Road:

I didn't bring the mesh bags with me so the outlet/ball valve on the boil pot got clogged with the hops.

We'll be getting a new used burner so we can be more efficient in our boil.

We'll either be making (depending on how easy it is to get supplies, which in China won't be easy) or ordering an immersion wort chiller.

Further down the road, we'll purchase a used fridge so we can throw our fermenter into it after primary and do a cold secondary.

Our brewmaster left once we pitched the 1st round of hops, so we were on our own after that. Any mistakes will be chalked up to that, but I am hopeful that we did well.

Would like to cut the time down by at least an hour next time around (April 10th or so) and then once we get the wort chiller, I would expect us to save an additional hour.

I have lots of pictures, but I guess I can't upload them until I have more posts.

10 gallon batch - 80 min boil.

10kg of grain - 9kg of pale malt, 500g of cara red, and 500g of cara pils.

Hops - whole cascade at 1st boil, then qingdao flower at 20min, 40 min, 60min and cascade & qingdao flower for last 30 seconds.

We heated the sparge water (7 gal) and initial water for the LT (8g) on my buddy's stove. 1st pull reading was 1.083. Last pull reading was 1.012. Once we got 11 or so gallons in the boil pot we moved the bot outside to the NG burner, but the burner turned out to be crap. We did test it when we first got it, and we weren't too happy with the purchase, but we figured we would give it a shot since the stove was giving us a weak boil. Needless to say the NG burner didn't do all that well and the flame kept blowing out. So we moved back inside and settled for the stove. 30g of whole cascade went in straight away, followed by 30g of qingdao flower 20 min later and 30g 40 minutes in, 40 g 60 min in, and 10 g of qingdao flower and 30 g of whole cascade for 1 turn of the boil at the end .

We lost about 1 to 1.5 gallons of water with the extended time it took to get the wort to a boil.

We chilled in a ice bath in the tub and got down to 26c in about 2 hours. We racked to our fermenter while running the wort through a fine mesh strainer.

Mixed two packets of Fermentis Safale S-04 in 26c spring water, mixed and then pitched to fermenter.

We aren't using an airlock, just a lid that rests on the fermenter.

24 hours later and we have action.

Will update this as we go.

Next Time and Down the Road:

I didn't bring the mesh bags with me so the outlet/ball valve on the boil pot got clogged with the hops.

We'll be getting a new used burner so we can be more efficient in our boil.

We'll either be making (depending on how easy it is to get supplies, which in China won't be easy) or ordering an immersion wort chiller.

Further down the road, we'll purchase a used fridge so we can throw our fermenter into it after primary and do a cold secondary.

Our brewmaster left once we pitched the 1st round of hops, so we were on our own after that. Any mistakes will be chalked up to that, but I am hopeful that we did well.

Would like to cut the time down by at least an hour next time around (April 10th or so) and then once we get the wort chiller, I would expect us to save an additional hour.

I have lots of pictures, but I guess I can't upload them until I have more posts.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

The closet where we keep the fermenters is closest to the bathroom so it is easier to just throw it up on that counter than to bring it into the kitchen.

The closet where we keep the fermenters is closest to the bathroom so it is easier to just throw it up on that counter than to bring it into the kitchen.