SexualCastles

Active Member

As per the title I have just finished my Jockey Box build, it uses a 1950's era Aluminium Ice Chest I got from ebay shipped from Illinois.

Cooling is handled by a 7 circuit cold plate I got from a bailiffs, 3 of the taps have a doubled up run for extra cooling and the 4th will have just a single run which I plan to use for stouts.

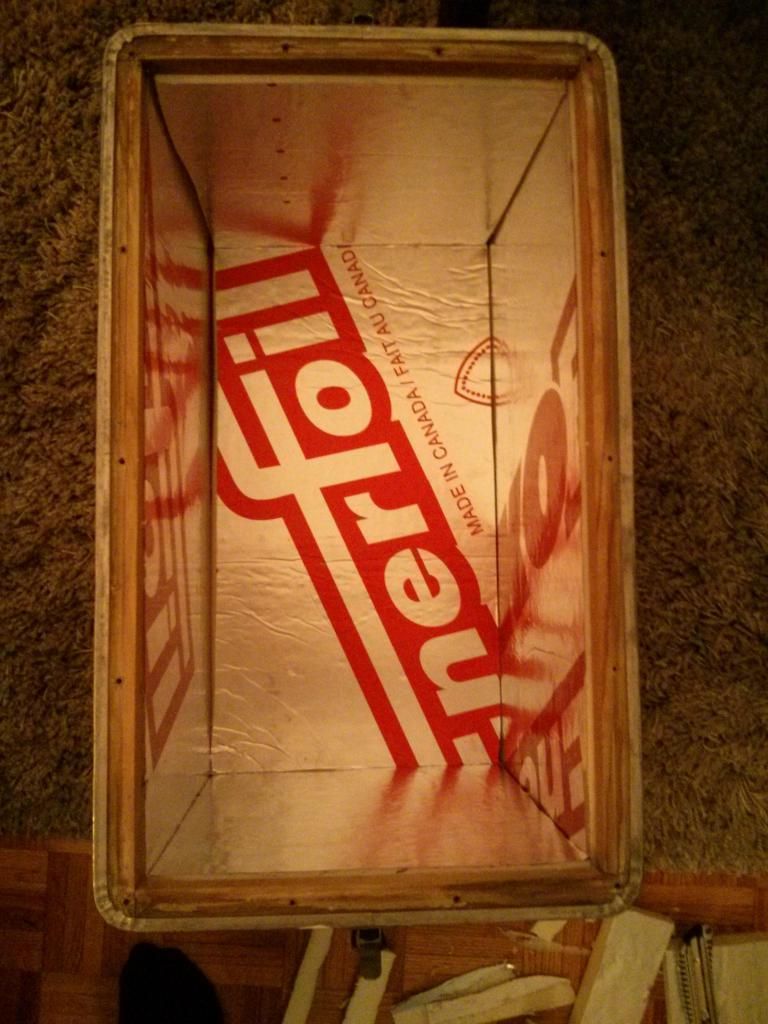

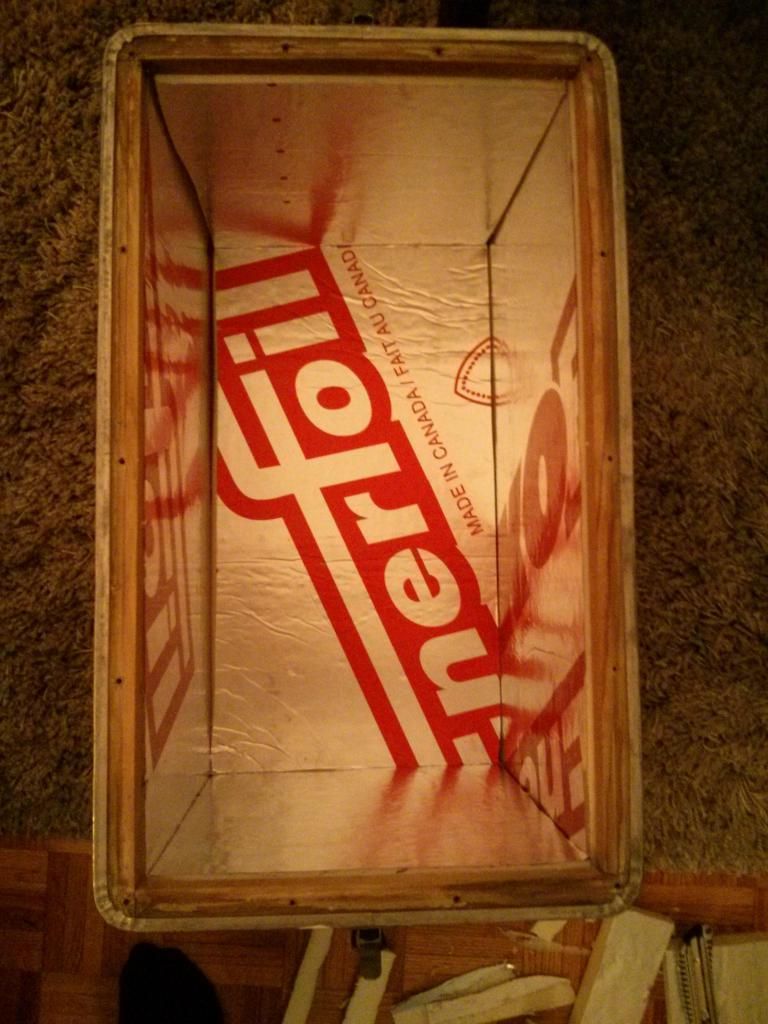

This is how I got the cooler:

After a bit of sanding and polishing I got it to the finish I was looking for:

Then I addressed the insulation, the old 50's stuff basically fell apart in my hands as I was removing it, dust from it went everywhere so hopefully it didn't contain any asbestos!!

I went and got some new R6 rated insulation board and trimmed to fit, almost cut off my hand in the process..

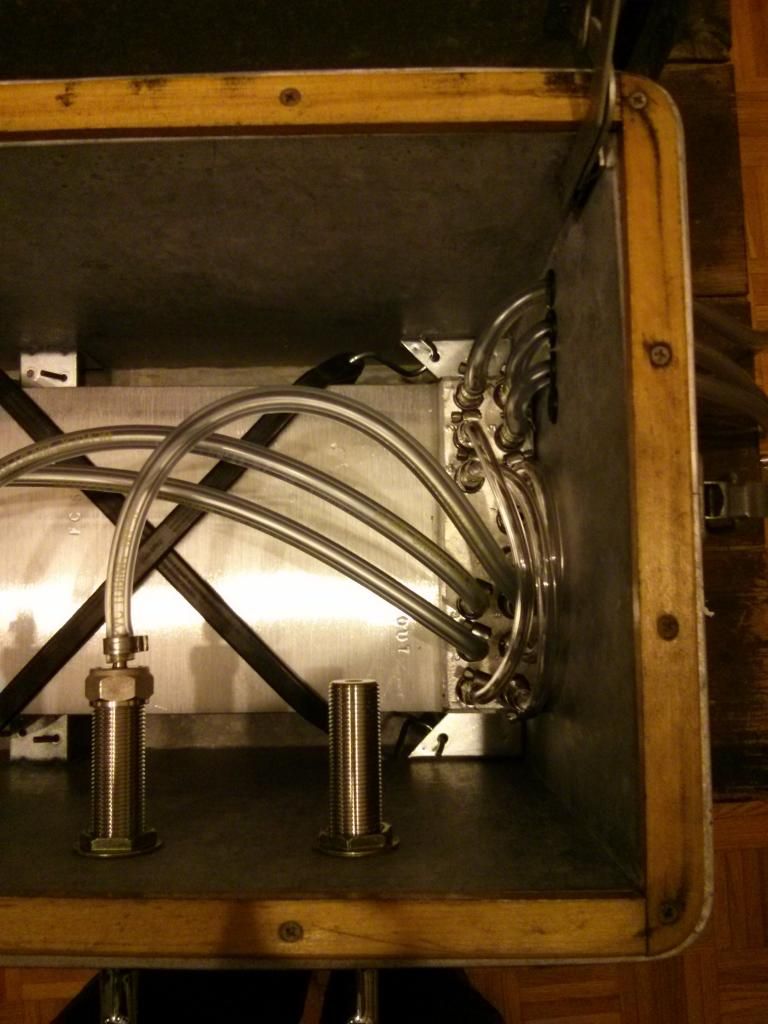

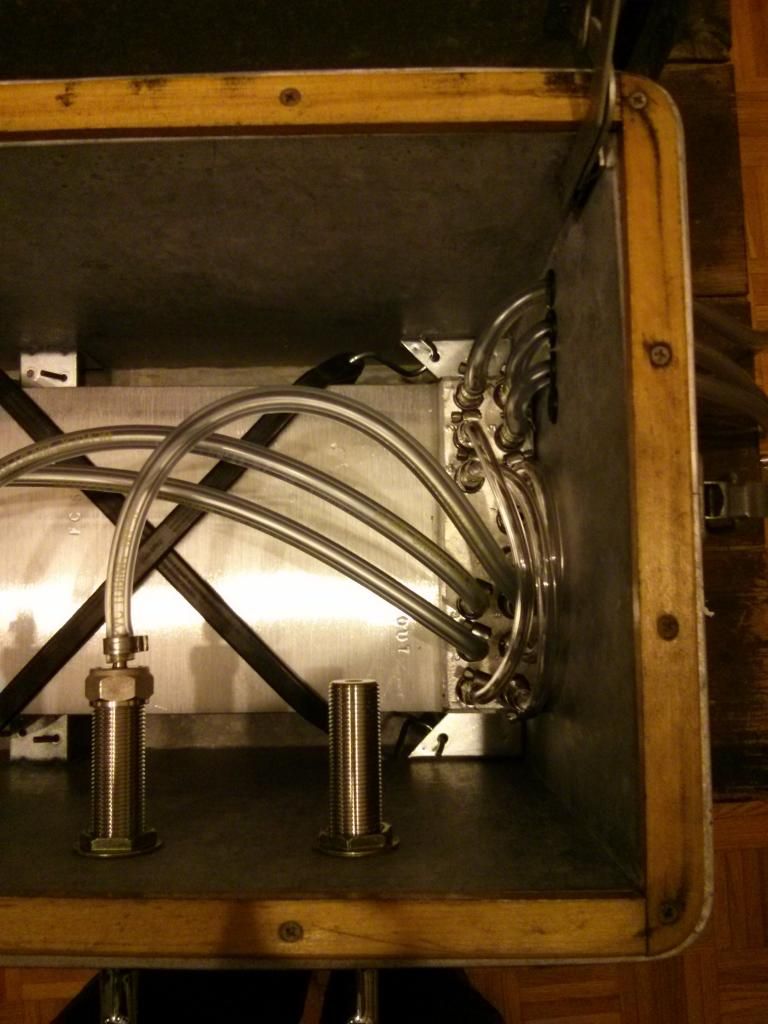

I then added some brackets to support the plate chiller and keep it elevated above any water from the melted ice as that will effect its efficiency:

And finally drilling holes for the taps and to run the lines into the box, I used a 9/16 drill bit for the lines in order to use correct sized rubber grommets and a 22mm bit for the taps:

Now all that is left to do is wait till Saturday for my double IPA to be fully carbed and pull a pint out of it!

Cooling is handled by a 7 circuit cold plate I got from a bailiffs, 3 of the taps have a doubled up run for extra cooling and the 4th will have just a single run which I plan to use for stouts.

This is how I got the cooler:

After a bit of sanding and polishing I got it to the finish I was looking for:

Then I addressed the insulation, the old 50's stuff basically fell apart in my hands as I was removing it, dust from it went everywhere so hopefully it didn't contain any asbestos!!

I went and got some new R6 rated insulation board and trimmed to fit, almost cut off my hand in the process..

I then added some brackets to support the plate chiller and keep it elevated above any water from the melted ice as that will effect its efficiency:

And finally drilling holes for the taps and to run the lines into the box, I used a 9/16 drill bit for the lines in order to use correct sized rubber grommets and a 22mm bit for the taps:

Now all that is left to do is wait till Saturday for my double IPA to be fully carbed and pull a pint out of it!