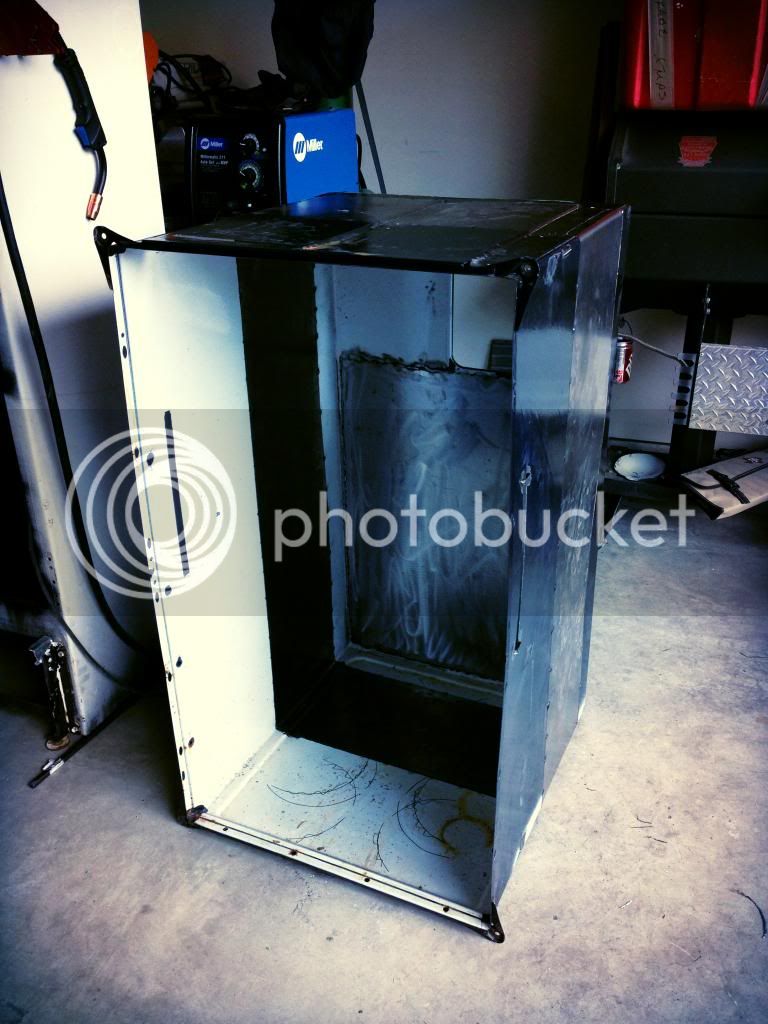

One of my favorite things about fabrication is building tools and or jigs to make other parts. I really enjoy it when home made things come out looking like they came from a factory. With that being said, I've got a lot of things to learn, but patience and research (and a little bit of money!) seem to help.

A major part of this kegerator is the plumbing. There will be 4 kegs which means 4 regulators which means an air manifold, CO2 in, 4 lines to the regulators, 4 lines from regulators to kegs, 4 lines from keg to door jamb, 4 expansion joints, 4 lines to the faucets and finally 4 faucets coming out the door.

Naturally all of this plumbing will have to be in stainless steel. Naturally. The cheapest way to buy stainless tubing is in coils. Which are round. Which make plumbing straight lines hard.

How do you straighten that tubing? There is a lot of material on the net, mainly from hot rod types, on how to do this. I've heard wacko stuff like roll the tubing between 2x4s in your hands, uncoil it into the corner of the garage floor and wall using your feet... All of which don't give straight tubing or that "factory" finish that I mentioned.

So, my inspiration was the $2-300 tubing straighteners that you find online. The goal was to build one for about $20 and have it be expandable for different sizes of tubing down the line. Easy. :lol_hitti

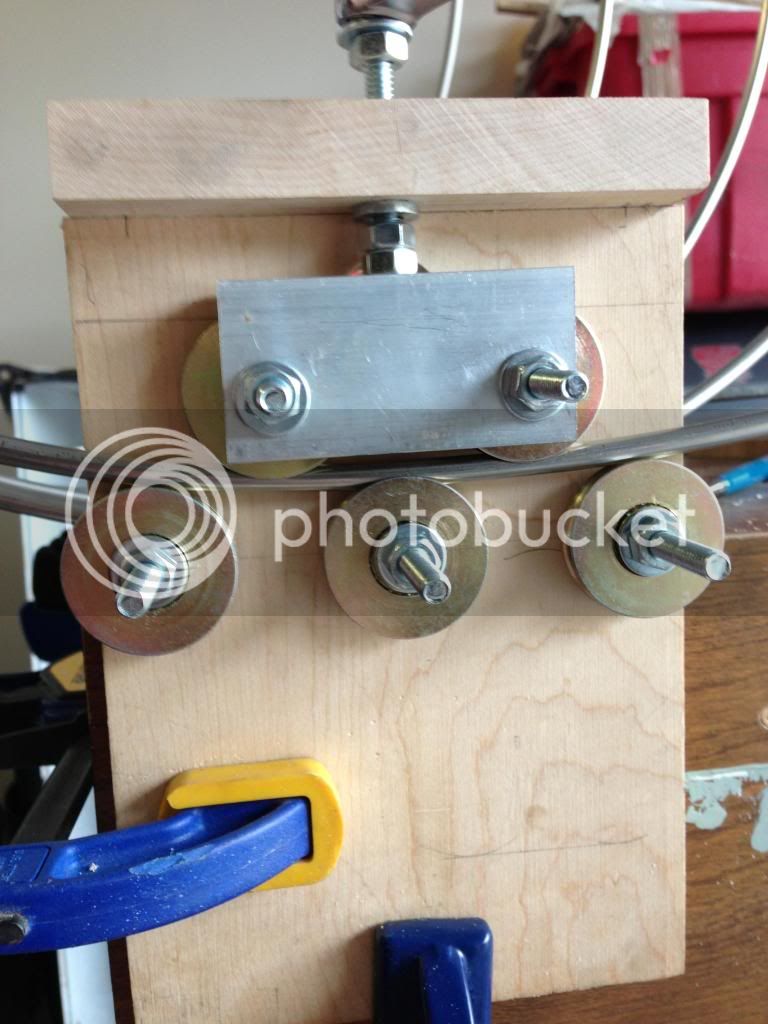

Enter the roller. From a glass door kit.

They are 1.5" diameter wheels, ball bearing action. They have a little bit more slop than a pro rig would have, but they were about $3 per pair. I bought 3 pair. I bought them from Amazon, about half the price of a large orange store in the area.

Grab some hardware from that orange store, (story on that to come) and some hard maple from the scrap bin. Lay everything out with a piece of stainless that I bent up with my crappy 3in1 tubing bender. Looks OK.

I bought 8 1/4"x2.5" carriage bolts, two packs of washers and nuts, some captive nuts and some all thread couplers just for in case. Long story short, the carriage bolts were from the bulk bin, no tag. The cashier charged them to me as 5/16" split washers. They rang up as 1 penny more than the bolts that they are, but I figured 8 cents wasn't worth me lecturing someone on the difference in a washer and a bolt. Oh America....:dunno:

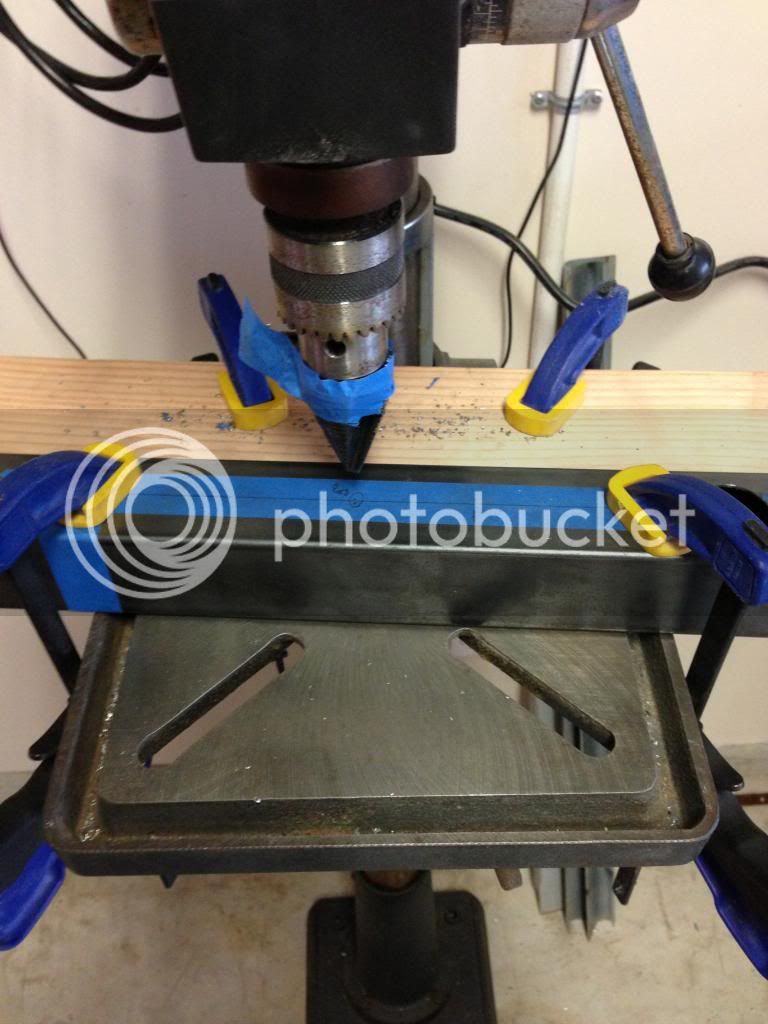

Drill some holes. Here's a trick I picked up last week while reading about drilling straight shelf alignment holes in cabinetry. The problem is getting them square without using a drill press. I had the same problem. I've chased the horrible runout on my drill press to the chuck. I used the marker test. I don't have a nice dial indicator with a magnetic base.

Bad chuck. Bad.

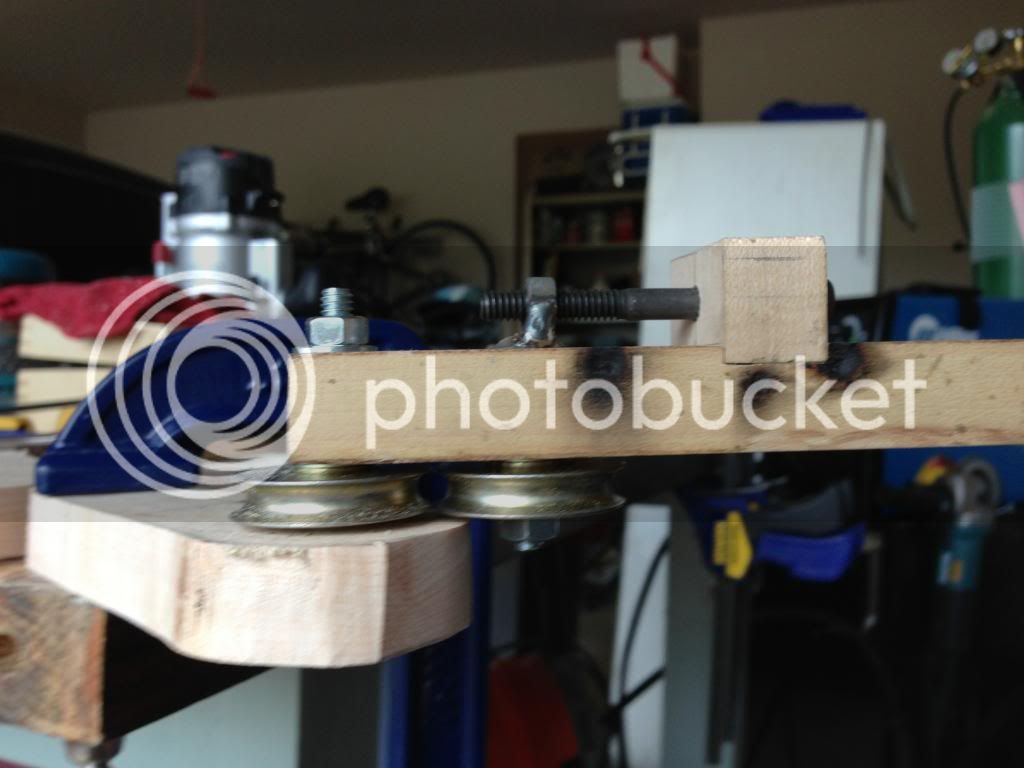

Oh yeah, the trick. Use your router to drill the holes. I have a plunge router and a bit that is exactly 1/4". Now, a nice spiral upcut bit would have been better, but my cheap-o straight 2 flute bit worked nicely. No egg shaped holes, perfectly square to the surface. I set up a temporary fence using scrap and some clamps for my centerline. It is imperative that the holes are all in the same plane or else you will coil your tubing instead of straightening it. I used my Incra rules to measure the offset of the bit to the router edge, mark the line and "plunge-drill" the holes.

I also routed the sliding grooves for the two top rollers. Similar jig, similar measuring techniques. These aren't as critical, you just want them to be parallel.

Voila.

Here's the setup - minus the adjusting bar.

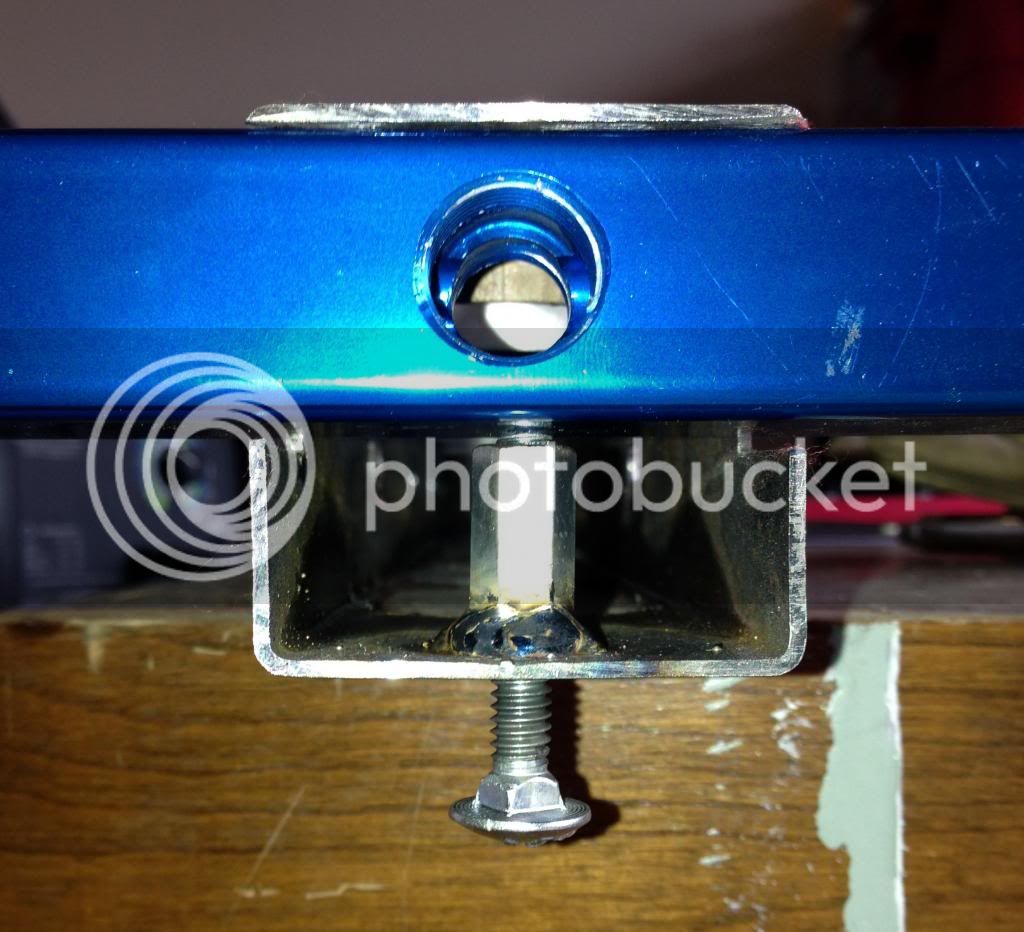

You'll notice that I squared the bottom of the slots to allow for the head of the carriage bolt to not bind in the rounded corners. One could probably use a regular hex bolt for these two. ***Edit - No you won't notice, I haven't uploaded that pic yet.***

Sorry to drag this out, but I didn't finish the slider bar - mainly because I'm thinking of changing the design. Note to everyone making one of these, it would probably be easier to make in steel. I didn't have anything that would work on hand.

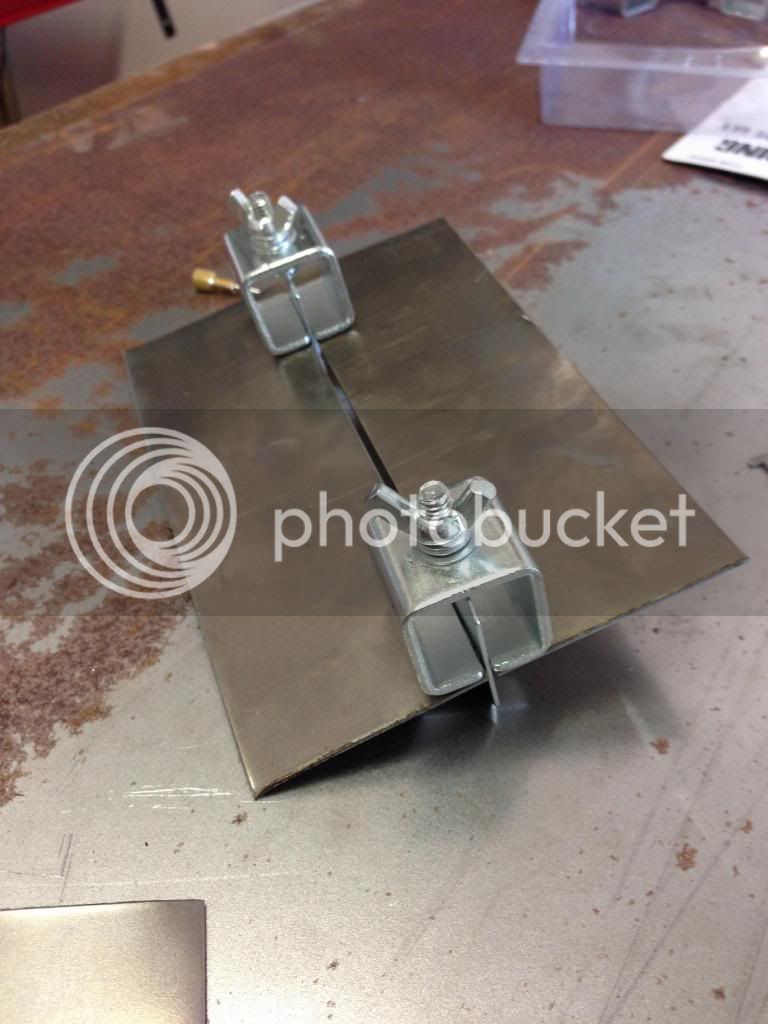

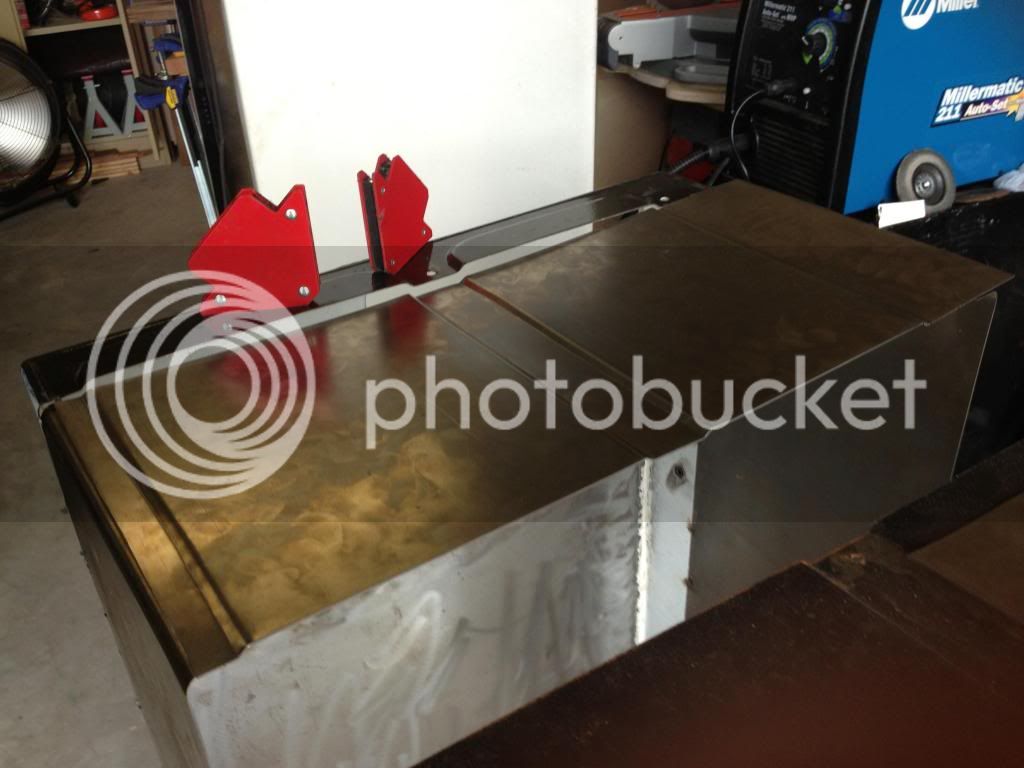

And an obligatory shot of stainless steel fitting goodness...

Stay tuned. Good chuck will make an appearance. Thanks for reading.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)