Yeah, I enjoy tasting other's homebrew as much as getting feedback on my own. It's fun to try to pull out ingredients and flavors from a beer someone else made. And most of them are really great and I've gotten many good ideas from trying them. And hopefully I'm able to provide some suggestions when a beer has flaws to help the brewer improve. It's a win-win, but I realize not everyone wants to evaluate a beer when they could just drink it.

Ok. You've convinced me that I need to be a part of this swap. I honestly would rather do swaps like this than to send my beers into competitions every month.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

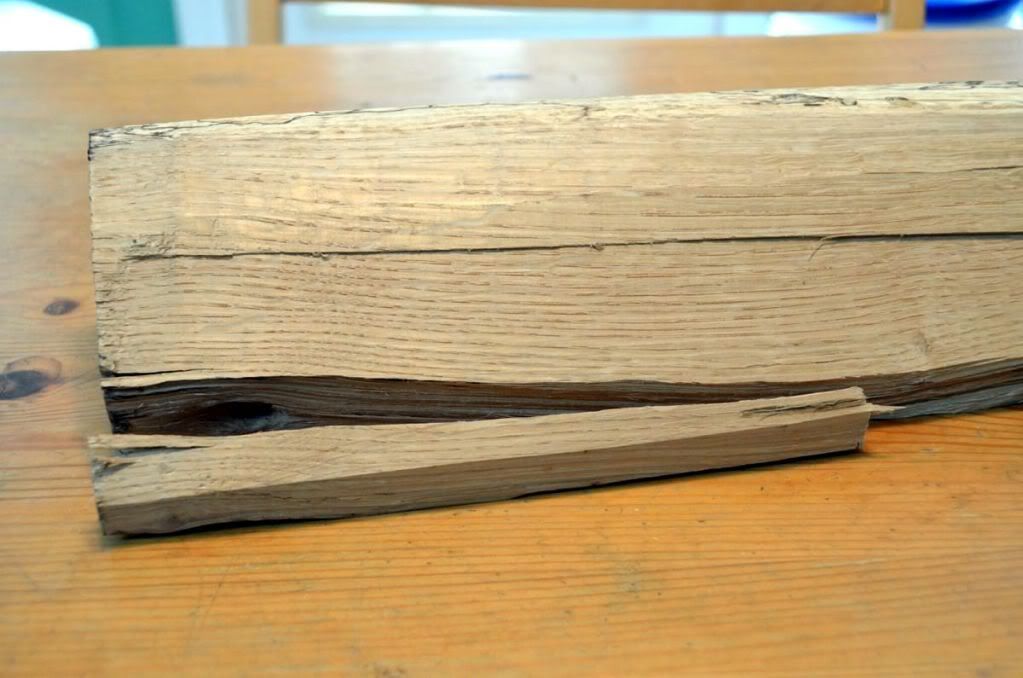

it's actually not that bad and will taste really good after aging on some oak then diluting down to 80 proof. my only problem with it is that it's called georgia moon but made in kentucky!

it's actually not that bad and will taste really good after aging on some oak then diluting down to 80 proof. my only problem with it is that it's called georgia moon but made in kentucky!