I was considering setting the mash tun into a larger pot with a sous vide to maintain temperature, but that also won't do steps. I'd have to take the mash tun out, heat it up on the stove, and then set it back into the sous vide (which would hopefully have hit new target temperate by then). And I'm not even sure if that would work, because with the tun removed, the water level would probably be too low to operate the sous vide.You oven won’t do 113, 147, 152, etc.

I just looked at the manual for that crock pot. It says in probe mode you can set the temp between 100 and 200 F.

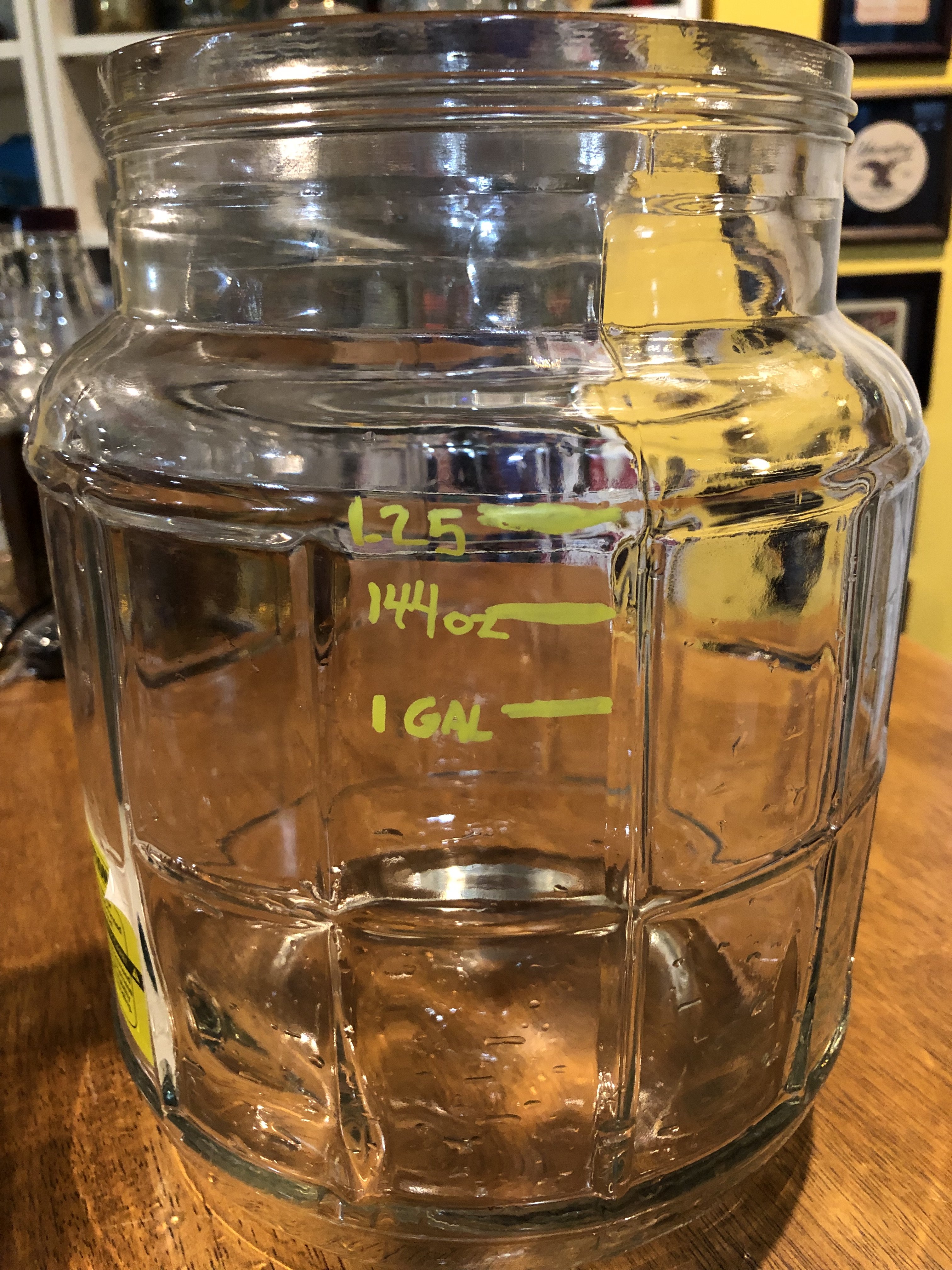

$50. This looks like it would work for grain for 1 gallon batches with a bag

Maybe a crock pot could work.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)