user 246304

Well-Known Member

- Joined

- Aug 24, 2017

- Messages

- 8,290

- Reaction score

- 9,851

I thought rather than taking another member's thread up with this issue, I'd post it here. Basically the issue is of solving venting issues with a system using the Banjo burner and a wind/heat shield; too close to the vessel bottom without a means to vent you get exhaust pooling and interference with the flame; you also get the potential for flame wrap around, and so heating your valves, thermos, etc.

One solution I've seen, as triggered in a conversation with day_trippr, is to have the back horizontal member dropped 2" to allow the split-screen capability and mounting on the back dropped member, as shown on Brewershardware.com's site:

Seems obvious that it's a great solution. Pity the soul who stands in back of the rig!

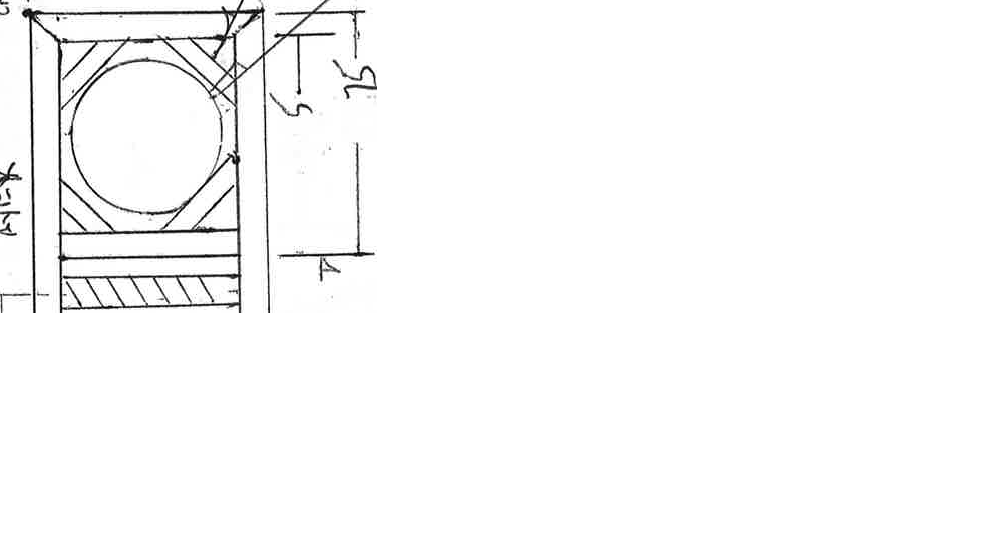

However, I'm nervous about losing that back member as a support for my 20 gallon vessels. In my design, I actually employ corner gussets as well (excuse the drafting and writing):

Inviting thoughts on venting, while keeping that back support member - or on why that support member is unnecessary. Because the split screen emptying out the back is a very elegant solution.

One solution I've seen, as triggered in a conversation with day_trippr, is to have the back horizontal member dropped 2" to allow the split-screen capability and mounting on the back dropped member, as shown on Brewershardware.com's site:

Seems obvious that it's a great solution. Pity the soul who stands in back of the rig!

However, I'm nervous about losing that back member as a support for my 20 gallon vessels. In my design, I actually employ corner gussets as well (excuse the drafting and writing):

Inviting thoughts on venting, while keeping that back support member - or on why that support member is unnecessary. Because the split screen emptying out the back is a very elegant solution.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)