suckerpunchltd

Well-Known Member

Hey all,

Reviewing kits, equipment, process, tools, ingredients now for some time. First forum I've joined for home brewing and just want to get a bit of feedback to make sure I'm not off my rocker...

I've kicked around extract vs. partial vs ag for a while now. I know the extract is the easiest to start with, but the on-going recipe and ingredients cost much more depending on where you get them from.

That said, I think I am going to just jump in head first with all grain.

As for equipment here's what I'm thinking:

Midwest has a decent starter kit right now for a good price (http://www.midwestsupplies.com/platinum-pro-beer-brewing-starter-kit.html) that comes with a 5-gallong kettle, buckets, bottler, auto-siphon and such. Mainly looking at this for the easy of getting fermentation, bottling, etc. from the get go in one purchase.

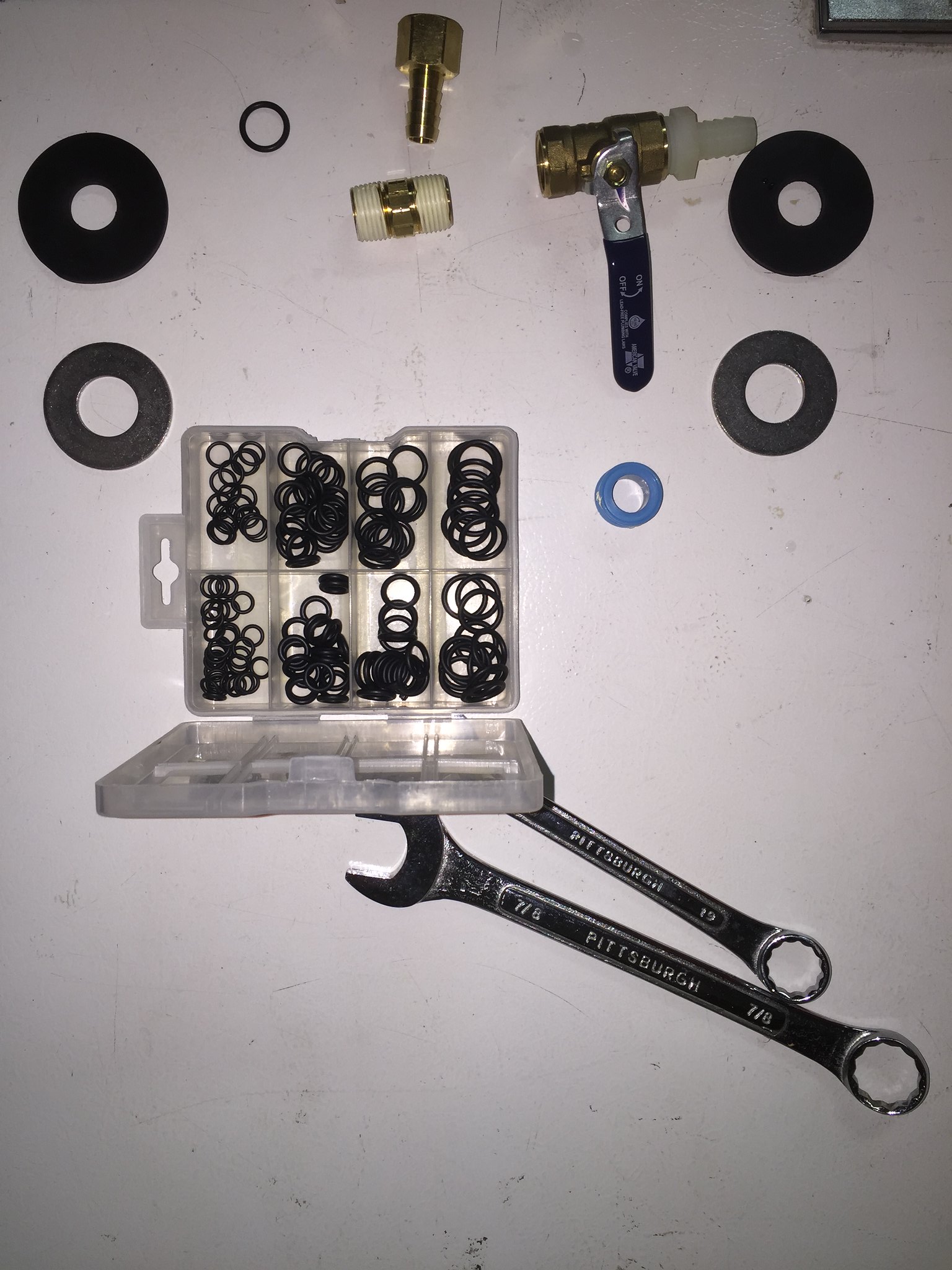

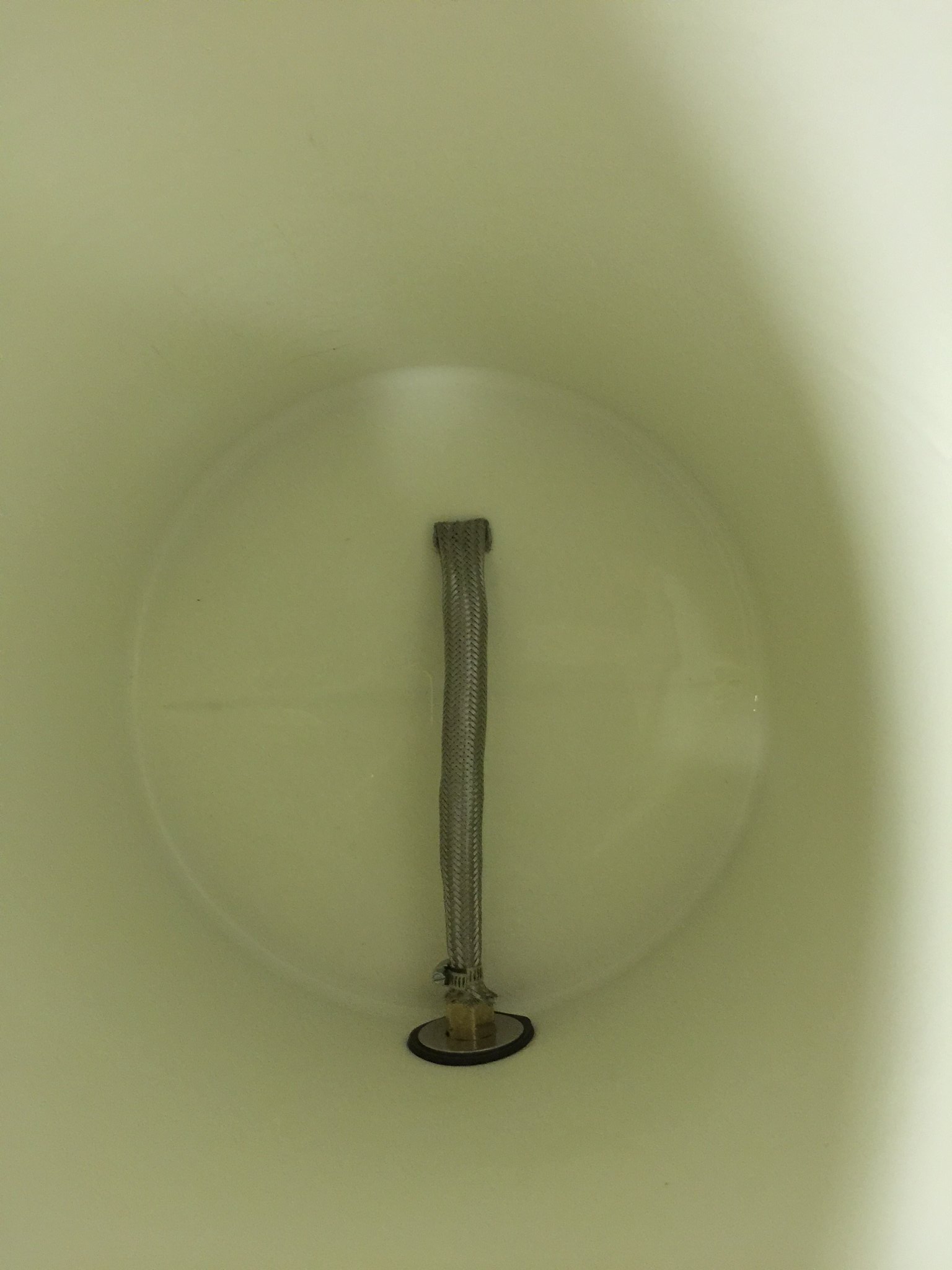

I have a 5-gallon igloo water cooler already on-hand I can convert to a MLT and either make or buy a false bottom or other system for lautering/sparging..

Thinking of a 36-quart kettle w/ propane burner for boiling wort and strike water and using the 5-gallon kettle from the kit for sparging. Will likely be doing batch sparging until I can make a sparge arm and hook up a flow system for that.

Keeping it to 5-gallon batches for the foreseeable future as it would seem to likely work best with the area I have to brew, ferment and store bottles at this time.

I've been reading quite a bit on recipes - measuring the temps during brewing, the original gravity, final gravity and even done some on water condition and how it changes the beer profile. Also been researching the different fermentables and hops to get an idea of what they may/may not impart, but still tons to learn.

So what do you all think? Seem okay to jump right to all-grain? Does the equipment and such I've put together seem a good starting point?

Thanks in advance for any insight or thoughts!

Reviewing kits, equipment, process, tools, ingredients now for some time. First forum I've joined for home brewing and just want to get a bit of feedback to make sure I'm not off my rocker...

I've kicked around extract vs. partial vs ag for a while now. I know the extract is the easiest to start with, but the on-going recipe and ingredients cost much more depending on where you get them from.

That said, I think I am going to just jump in head first with all grain.

As for equipment here's what I'm thinking:

Midwest has a decent starter kit right now for a good price (http://www.midwestsupplies.com/platinum-pro-beer-brewing-starter-kit.html) that comes with a 5-gallong kettle, buckets, bottler, auto-siphon and such. Mainly looking at this for the easy of getting fermentation, bottling, etc. from the get go in one purchase.

I have a 5-gallon igloo water cooler already on-hand I can convert to a MLT and either make or buy a false bottom or other system for lautering/sparging..

Thinking of a 36-quart kettle w/ propane burner for boiling wort and strike water and using the 5-gallon kettle from the kit for sparging. Will likely be doing batch sparging until I can make a sparge arm and hook up a flow system for that.

Keeping it to 5-gallon batches for the foreseeable future as it would seem to likely work best with the area I have to brew, ferment and store bottles at this time.

I've been reading quite a bit on recipes - measuring the temps during brewing, the original gravity, final gravity and even done some on water condition and how it changes the beer profile. Also been researching the different fermentables and hops to get an idea of what they may/may not impart, but still tons to learn.

So what do you all think? Seem okay to jump right to all-grain? Does the equipment and such I've put together seem a good starting point?

Thanks in advance for any insight or thoughts!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)