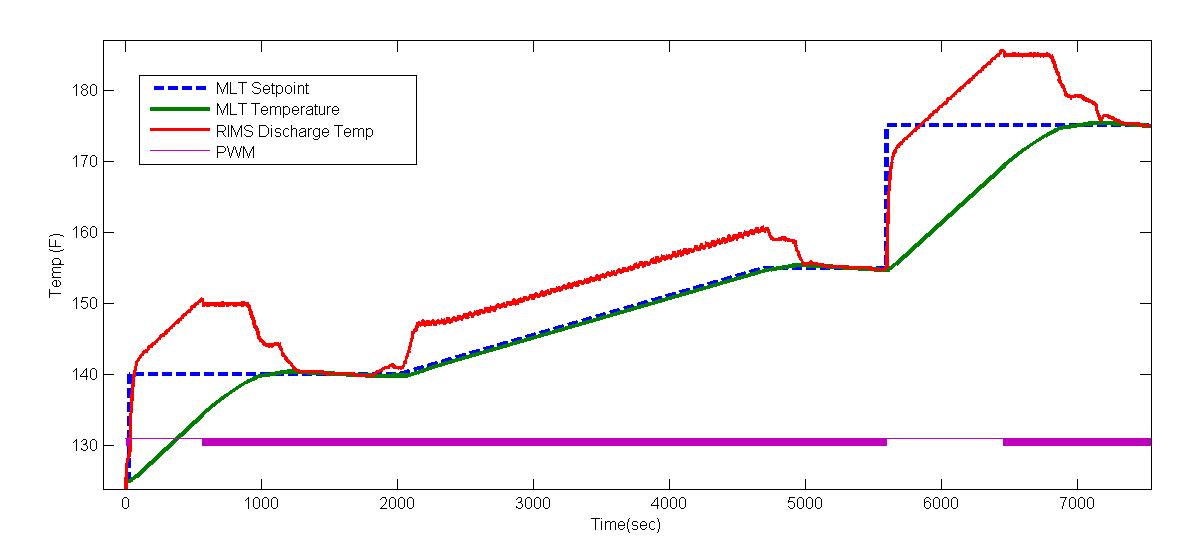

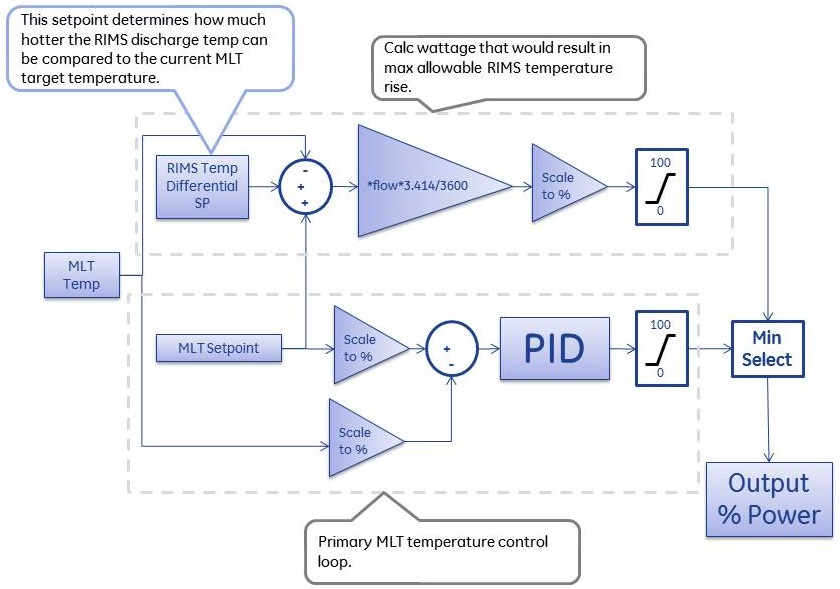

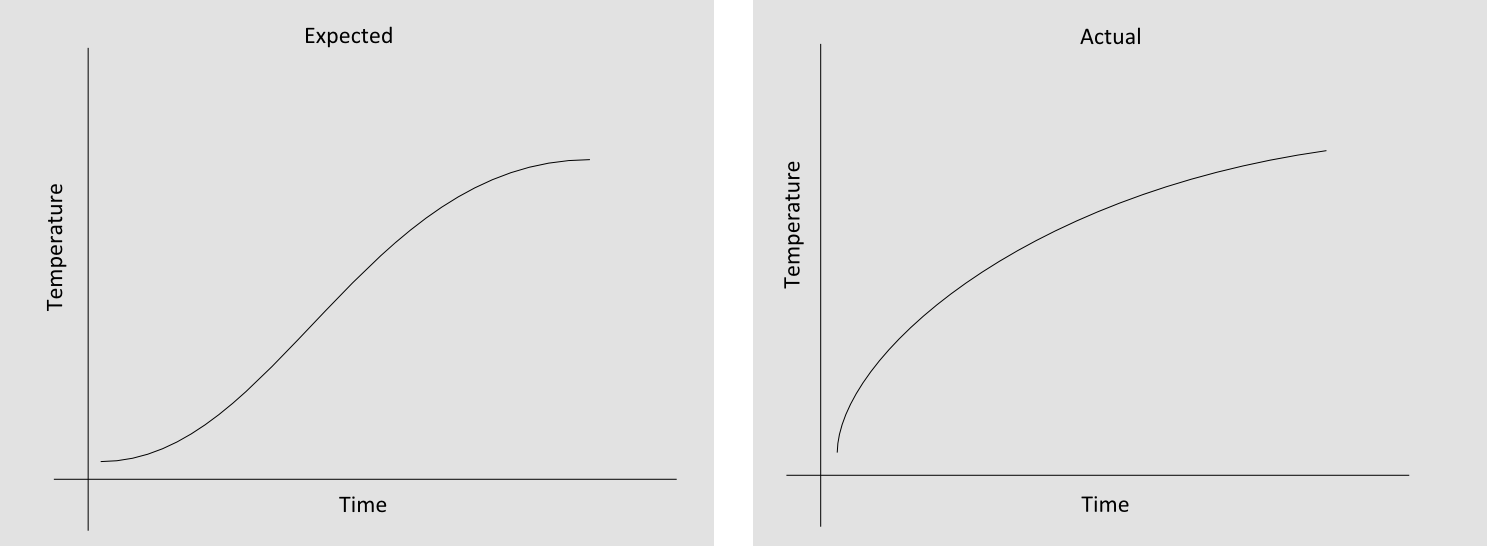

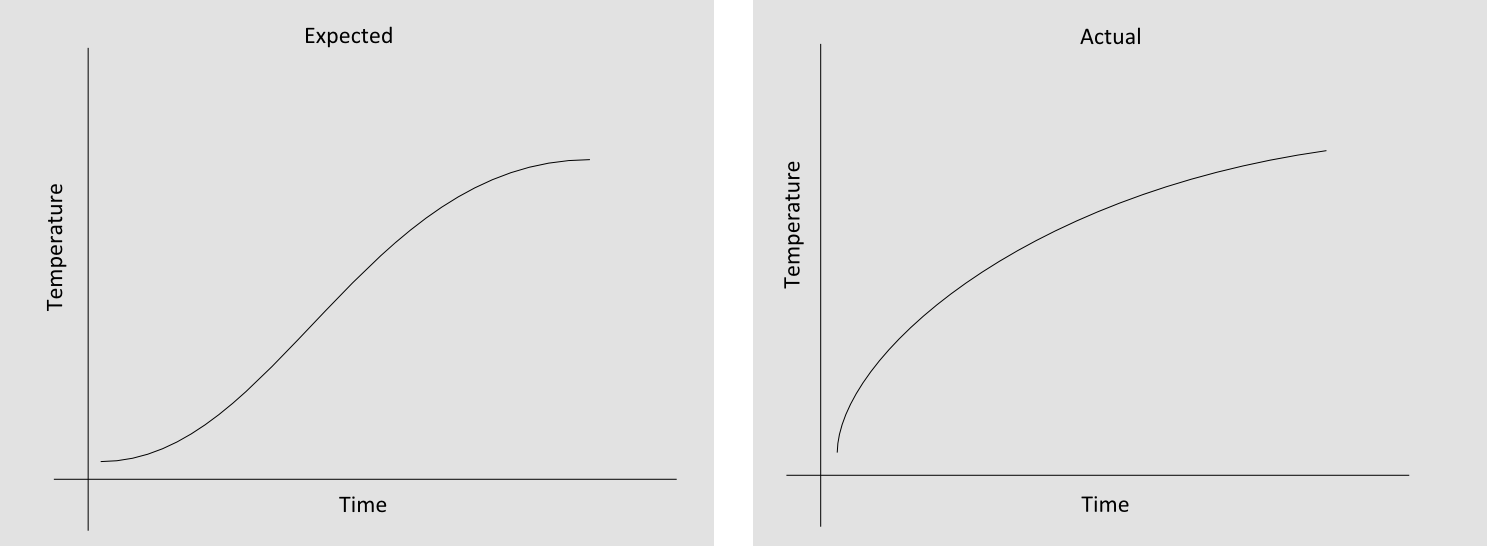

I'm building a homebrew PID controller for my RIMS tube with an arduino. I was running some tests the other day to calibrate and found that the system doesn't behave like I expected. When I increase the the power output of the heating element, instead of heat slowly ramping up because of 'dead-time' like I would expect it does the opposite! After bumping up the heat the temp shoots up really quickly, then gradually slows and starts to heat at a normal pace. Here is a quick drawing to try and illustrate what I'm talking about:

I have no real world experience with this kind of stuff, I can't think of why the system behaves this way vs the way I expected. Can any one enlighten me?

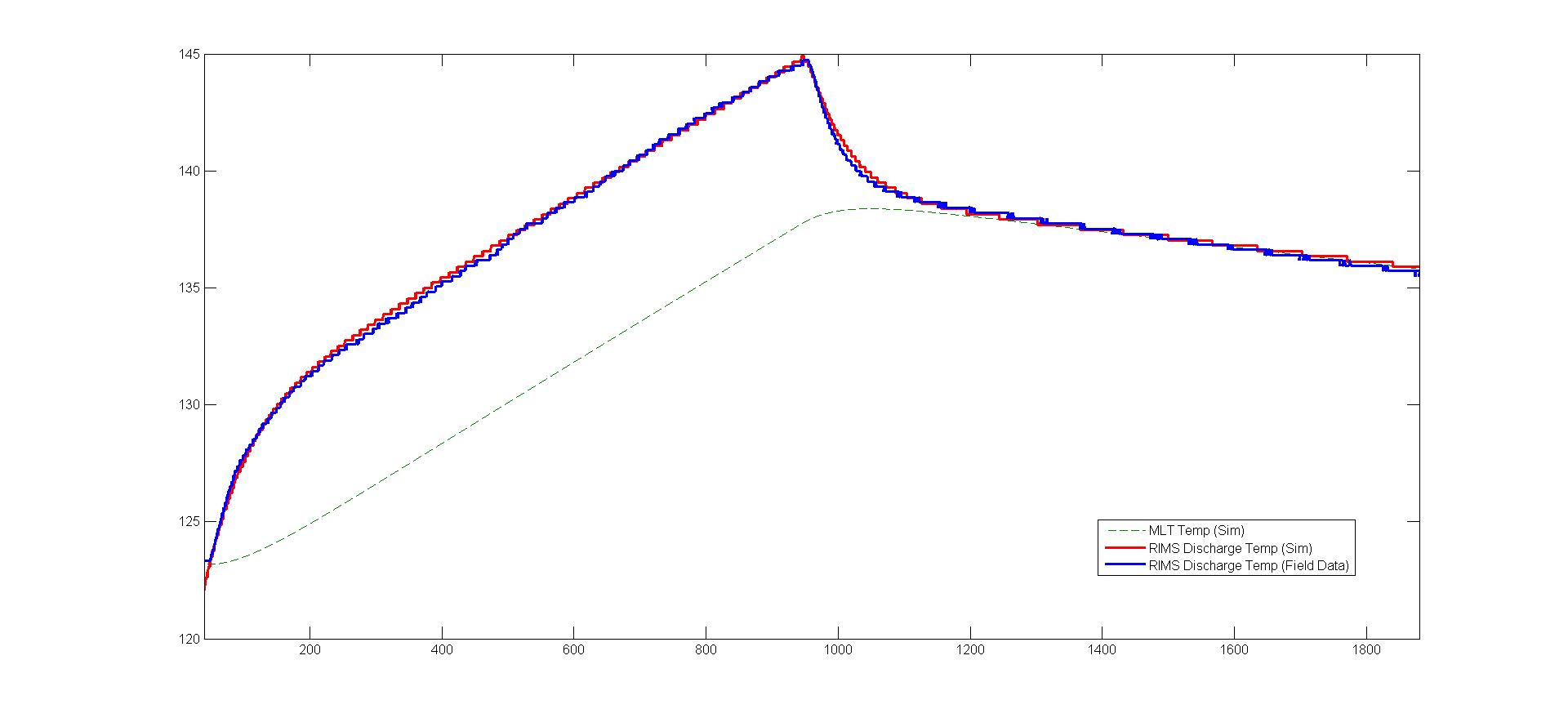

[Edit] These are temp readings taken from inside the RIMS tube 2 - 3 inches from the end of the heating element, after wort has passed over the element.

I have no real world experience with this kind of stuff, I can't think of why the system behaves this way vs the way I expected. Can any one enlighten me?

[Edit] These are temp readings taken from inside the RIMS tube 2 - 3 inches from the end of the heating element, after wort has passed over the element.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)