alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Hi!

I thought I'd give a short recap for new viewers.

As most of us know, the STC-1000 is a cheap but very useful dual stage thermostat. The aim of the STC-1000+ project is to implement a firmware better suited for fermentation control and the means to update the controller firmware in a cheap and easy manner.

I may be biased, but I think those goals have been met and then some. If you are able to do some light soldering, you can build a programmer and flash your controller for as little as $5 and the process should not take more than an hour.

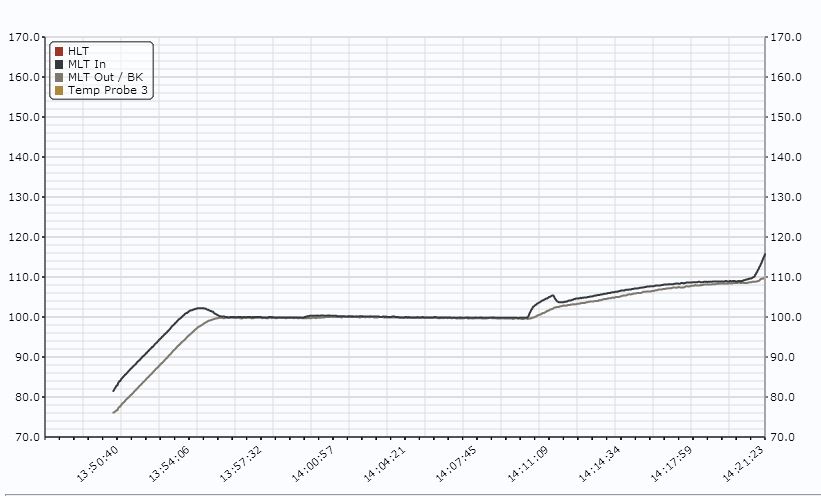

Early on in the process, I had an idea to also build a firmware with a PID regulation algorithm, that would be more suitable for mash control. I eventually settled on a PI regulation scheme instead (as the derivative action is more trouble than benefit in this application). Unfortunately, limited time to spare (and with the STC-1000+ project using up most of it) and technical difficulties has delayed this firmware. But now, the STC-1000+ firmware is reaching a point where I think it is pretty decent and I have also solved some issues, so I think it is time get this project rolling.

The project page; https://github.com/matsstaff/stc1000pi

(note: at this point there is not much there, as no 'official' release is out yet, but the current state of work can be found in the work branch)

Cheers!

I thought I'd give a short recap for new viewers.

As most of us know, the STC-1000 is a cheap but very useful dual stage thermostat. The aim of the STC-1000+ project is to implement a firmware better suited for fermentation control and the means to update the controller firmware in a cheap and easy manner.

I may be biased, but I think those goals have been met and then some. If you are able to do some light soldering, you can build a programmer and flash your controller for as little as $5 and the process should not take more than an hour.

Early on in the process, I had an idea to also build a firmware with a PID regulation algorithm, that would be more suitable for mash control. I eventually settled on a PI regulation scheme instead (as the derivative action is more trouble than benefit in this application). Unfortunately, limited time to spare (and with the STC-1000+ project using up most of it) and technical difficulties has delayed this firmware. But now, the STC-1000+ firmware is reaching a point where I think it is pretty decent and I have also solved some issues, so I think it is time get this project rolling.

The project page; https://github.com/matsstaff/stc1000pi

(note: at this point there is not much there, as no 'official' release is out yet, but the current state of work can be found in the work branch)

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)