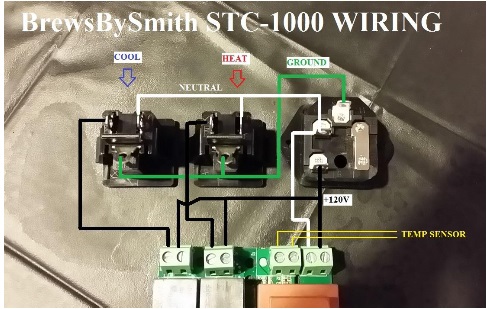

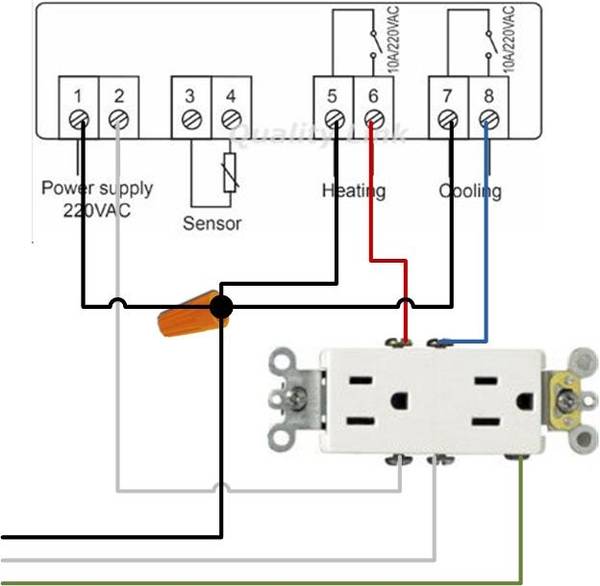

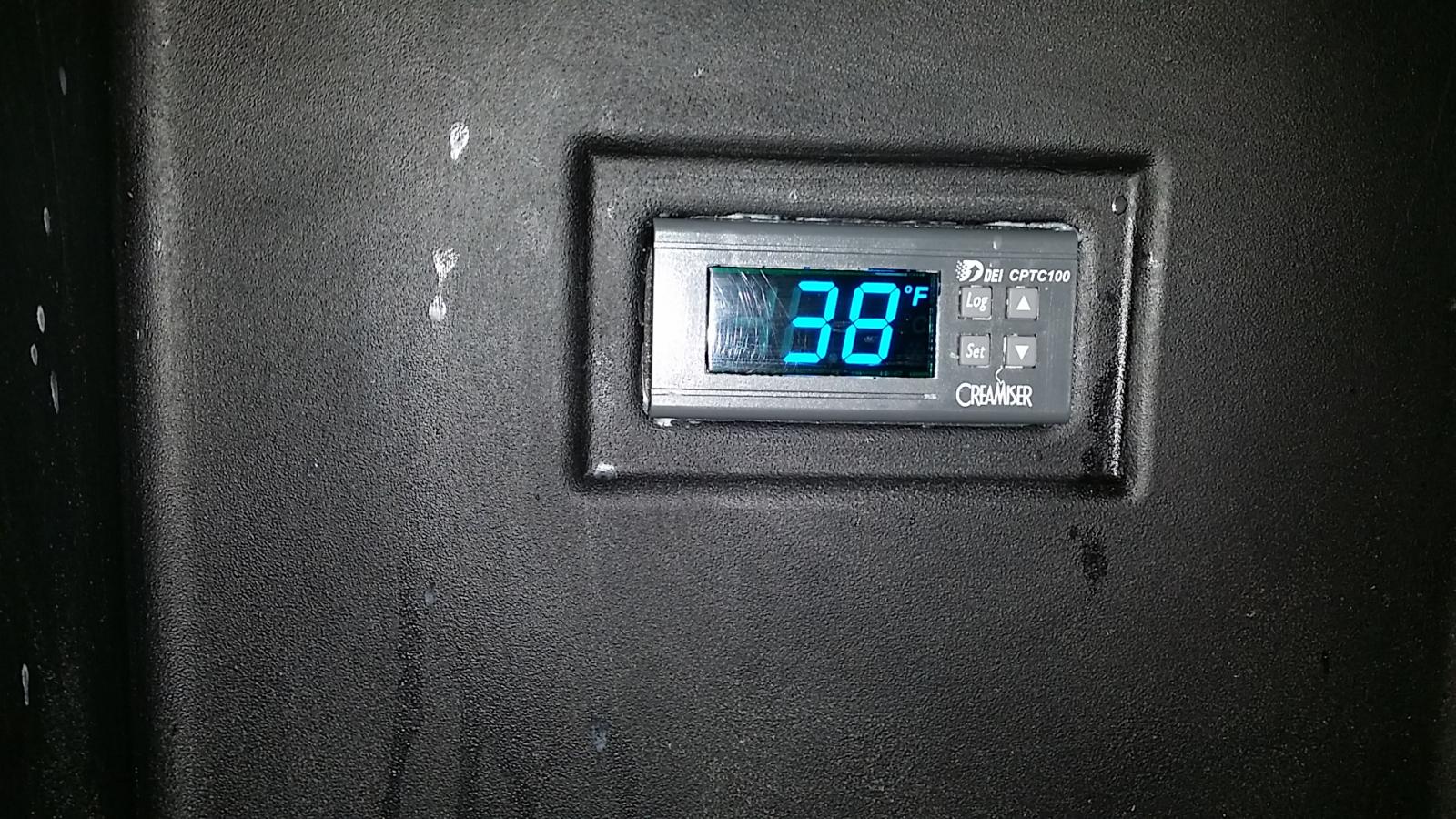

I flashed 2 STC 1000 controllers today, thought I'd share my experiences for the next to follow suit. First, however a HUGE thanks to Alpha for this upgrade, great work I can't wait to get it installed on my new ferm chamber. Then, thanks go out to Wil Conrad, for his You tube tutorial. The documentation by alpha is top notch, and the video added quite a value to us newbies too, so thanks!

I work in finance and have worked within an IT environment on numerous projects, but never on hardware, so I'm as newbie as they come! (I googled, and wiki'd everything from PID to PWM and more!). Here's my observances:

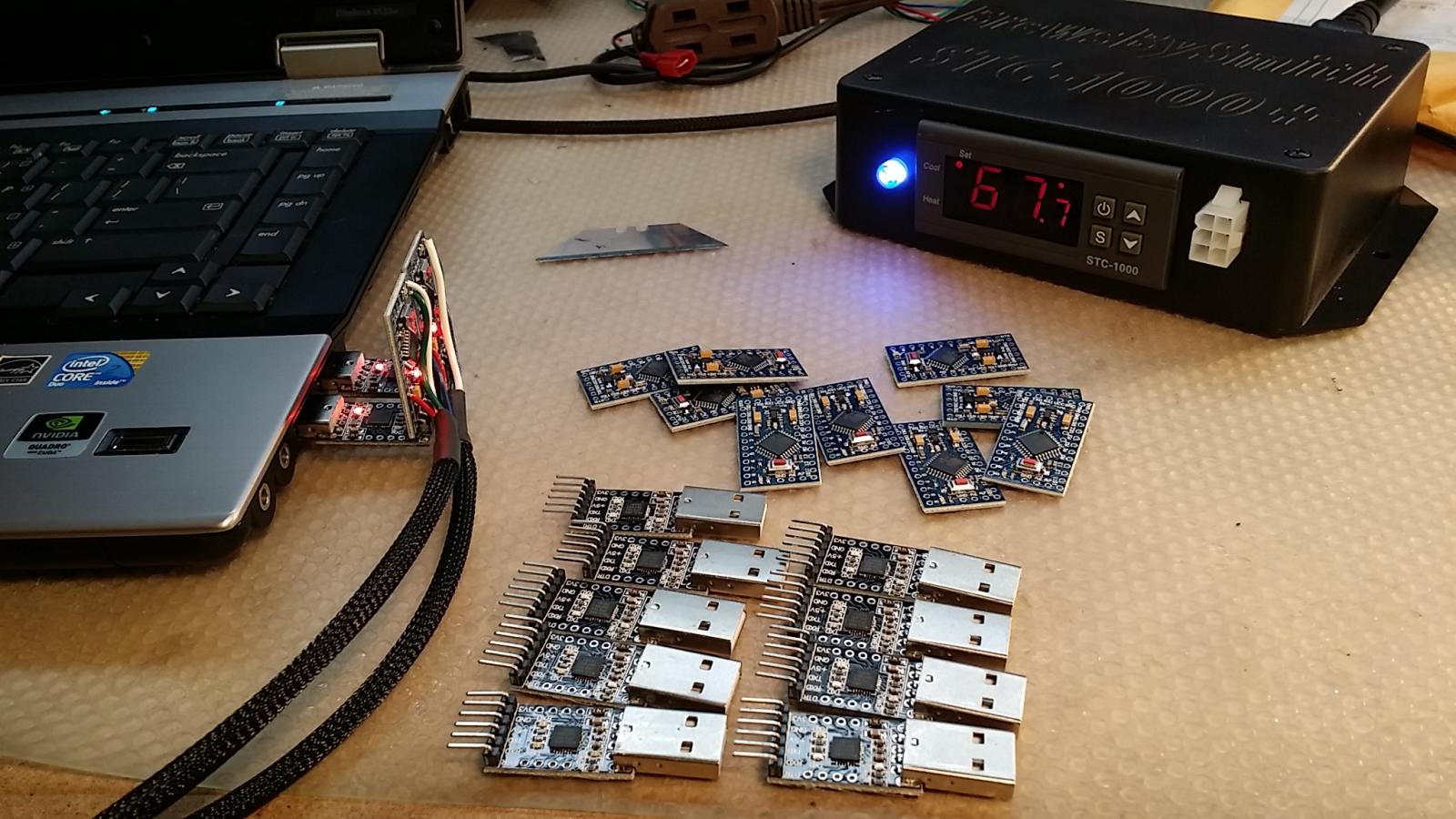

Flashed STC 1000+ using an Arduino Uno I picked up at Radio Shack, $27, had some old Amex Gift cards lying around so it was cheap! I wired it in with jumper cables as RS didn't have DuPont cables (I could've waited for Amazon of course too), and I didn't have a pin head, so fashioned this by wiring it up (via the aforementioned great documentation from Alpha) from the Arduino first, then straightening out the ends and cutting them to all come out to the same length. I chose not to solder, just hold after cleaning the solder with alcohol and scratching a bit w/my screwdriver. I attached all 5 wires onto some duct tape (and folded over). Voila! A somewhat stable pin header. I had to fuss with it to get to the right width a bit, but ended up ok. After a few trial and errors to flash (my laptop kept dropping my com port the Arduino was hooked to, and at one time I found one of my wires disconnected from the Arduino) I finally got it to "see" the STC 1000 and flash away. I was surprised when an alarm went off (not terribly loud) as I had the sensor probe hooked up. When I was done, after the mosquito noise, (spoiler alert, skip to the end!) I had to laugh at the line of output that read "writing magic". Very funny! Then I decided to flash the 2nd STC, and as I was unhooking the temp probe (used the same one) that's when I noticed one end had come free- thus the sound. But I checked the 1st one and the temp read Farenheit, so seems ok. I flashed the 2nd one in ....well, a flash! Had the laptop drop out the com port but replug and away I went. This time no buzzer noise, the temp probe stayed in. I'm very happy with the ease of this, and can't wait to use in the new ferm chamber. Thanks to all here as well who wrote about their experiences!